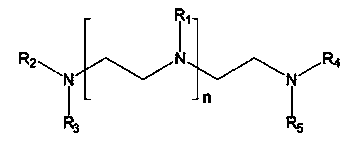

Reproducible polytertiaryamine sulfur dioxide absorbent and preparation method thereof

A technology of polybasic tertiary amines and sulfur dioxide, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of high industrial cost and operation cost, easily oxidized absorbent, unfavorable practical application, etc., and achieve high absorption , low toxicity, large absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of renewable polyvalent tertiary amine sulfur dioxide absorbent comprises the following steps:

[0026] Connect the three-necked flask to a reflux condenser, a constant pressure dropping funnel, and a stirring device. Add triethylenetetramine to the three-necked flask, add excess formic acid, add formaldehyde aqueous solution dropwise according to the molar ratio of triethylenetetramine to formaldehyde 1:6, and reflux for 48 hours. After the reaction was finished, excess formic acid and water were removed by normal pressure distillation, and the reaction product was evaporated by vacuum distillation. The product is a colorless transparent liquid, and the product is placed in a desiccator for later use.

[0027] Accurately weigh the above product with a balance, dissolve it in a certain amount of water, add a small amount of hydroquinone, a small amount of methylethanolamine, and an appropriate amount of phosphoric acid, and the composition of the...

Embodiment 2

[0031] The preparation method of renewable polyvalent tertiary amine sulfur dioxide absorbent comprises the following steps:

[0032] Connect the three-necked flask to a reflux condenser, a constant pressure dropping funnel, and a stirring device. Add diethylenetriamine to the three-necked flask, add excess formic acid, add formaldehyde aqueous solution dropwise according to the molar ratio of diethylenetriamine and formaldehyde of 1:5, and reflux for 24 hours. After the reaction was finished, excess formic acid and water were removed by normal pressure distillation, and the reaction product was evaporated by vacuum distillation. The product is light yellow transparent liquid, put the product in a desiccator for later use.

[0033] Accurately weigh pentamethyldiethylenetriamine with a balance, dissolve it in a certain amount of water, add a small amount of hydroquinone, a small amount of methylethanolamine, and an appropriate amount of sulfuric acid, and the composition of th...

Embodiment 3

[0037] The preparation method of renewable polyvalent tertiary amine sulfur dioxide absorbent comprises the following steps:

[0038] Connect the three-necked flask to a reflux condenser, a constant pressure dropping funnel, and a stirring device. Add pentaethylene hexamine and a small amount of palladium-carbon catalyst in the three-necked flask, add formaldehyde solution dropwise according to the molar ratio of pentaethylene hexamine and formaldehyde of 1:8, and at the same time pass hydrogen into the reaction flask, and reflux for 48 hours. After the reaction was finished, after removing water and low-boiling impurities by distillation under normal pressure, the reaction product was evaporated by distillation under reduced pressure. The product is a colorless transparent liquid, and the product is placed in a desiccator for later use.

[0039] Accurately weigh the above product with a balance, dissolve it in a certain amount of water, add a small amount of hydroquinone, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com