Method for preparing anode catalyst of direct methanol fuel cell

A methanol fuel cell and catalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the catalytic activity of the catalyst cannot be fully utilized, it is difficult to achieve uniform dispersion and molecular scale, small ratio Surface area and other issues, to achieve good application prospects, good electrocatalytic oxidation activity and efficiency, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

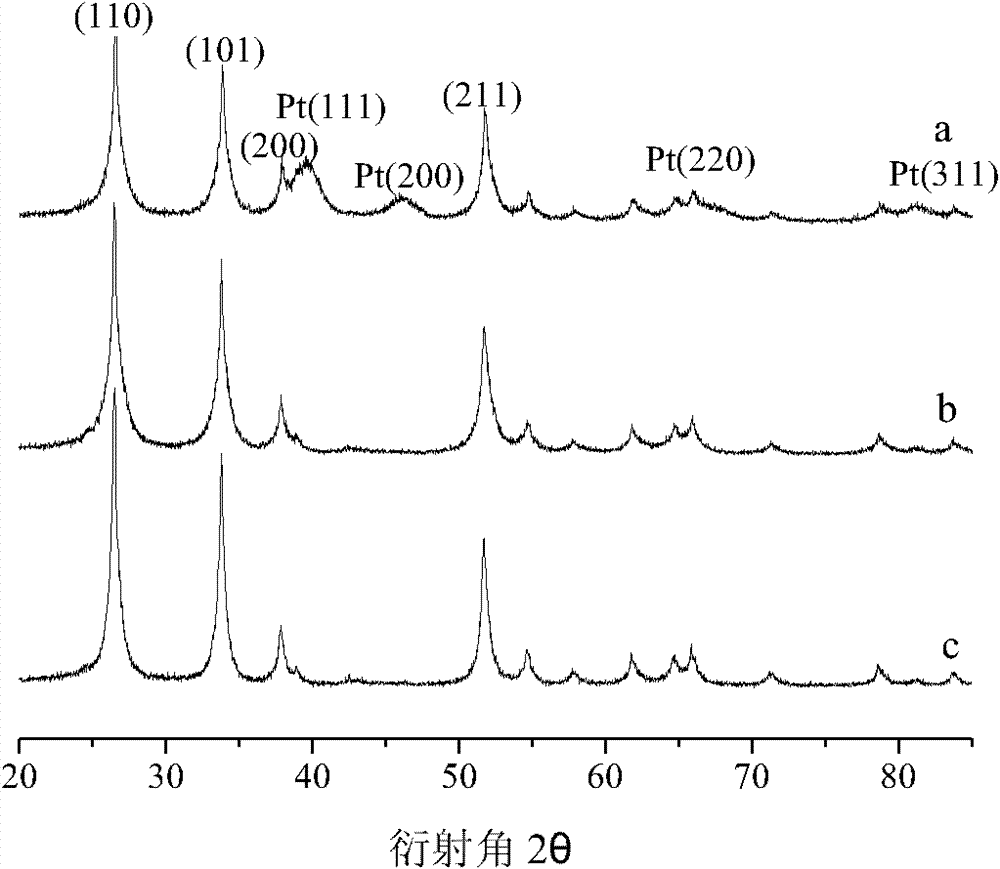

Embodiment 1

[0020] Take 2.0 g of SnCl 4 ·5H 2 O, 0.05 g SbCl 3 and 3.0 g of carbon black were dissolved in 200 ml of absolute ethanol, and stirred well. Then NaOH solution was added dropwise to the mixed solution until pH=9.0. After two hours of reaction, it was filtered, washed three times with absolute ethanol, dried at 100°C in an air atmosphere for 2 hours, and then calcined in a muffle furnace at 600°C for 2 hours to obtain an ATO / C mixture. Take 3.0 g H 2 PtCl 6 ·xH 2 O was dissolved in 100 ml of ethylene glycol containing 0.1 M, and reacted in an inert gas atmosphere at 140 °C for 30 minutes to obtain a sol containing elemental Pt. Then the reacted slurry was mixed with ATO / C, stirred for 2 hours, and then the pH value was adjusted to 7.0 with 1 M sulfuric acid solution. After filtration, it was dried in an oven at 130° C. for 2 hours to obtain the catalyst Pt-ATO / C.

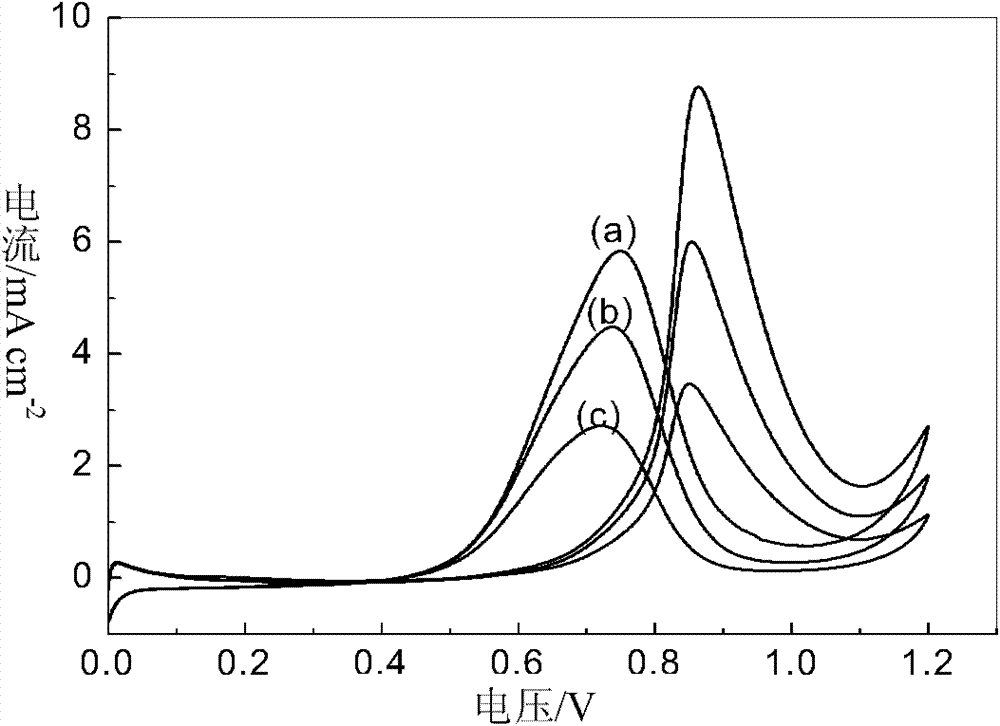

[0021] pass figure 2 It can be concluded that, with Pt-SnO 2 / C Compared with the commercial catalyst P...

Embodiment 2

[0023] Take 7.0 g of SnCl 4 ·5H 2 O, 0.45 g SbCl 3 and 30.0 g of carbon black were dissolved in 400 ml of absolute ethanol, and stirred evenly. Then 0.2M NaOH solution was added dropwise to the mixed solution until the pH value = 10.0. After reacting for two hours, it was filtered, washed three times with absolute ethanol, dried in a vacuum oven at 80°C for 2 hours, and then calcined in a muffle furnace at 750°C for 2 hours to obtain an ATO / C mixture. Take 9.0 g H 2 PtCl 6 ·xH 2 O was dissolved in 200 ml of ethylene glycol containing 0.1M NaOH, reacted in an inert gas atmosphere at 130 °C for 30 minutes, then mixed the reacted slurry with ATO / C, stirred for 2 hours, and then washed with 1M nitric acid solution Adjust the pH to 6.0. Then filter and dry in an oven at 120° C. for 2 hours to obtain the catalyst Pt-ATO / C.

Embodiment 3

[0025] Take 10.0 g of SnCl 4 ·5H 2 O, 0.65 g SbCl 3 and 11.0 g of carbon black were dissolved in 400 ml of absolute ethanol, and stirred evenly. Aqueous ammonia was then added dropwise to the mixed solution until the pH value = 5.0. After reacting for 2 hours, filter, beat and wash with deionized water three times, dry in air atmosphere at 100°C for 2 hours, and then calcinate in a muffle furnace for 2 hours to obtain an ATO / C mixture. Take 18.0 g H 2 PtCl 6 ·xH 2 O was dissolved in 500 ml of ethylene glycol containing 0.1M NaOH, reacted in an inert gas atmosphere at 130 °C for 40 minutes, then mixed the reacted slurry with ATO / C, stirred for 2 hours, and then washed with 1M sulfuric acid solution Adjust the pH to 5.0. Then filter and dry in an oven at 120° C. for 2 hours to obtain the catalyst Pt-ATO / C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com