Environmental-function nano material Cu-Fe/TiO2 nanotube array, and preparation and application thereof

A nanotube array and functional nanotechnology, applied in the field of photocatalysis, can solve the problems of insufficient specific surface area, only absorption, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

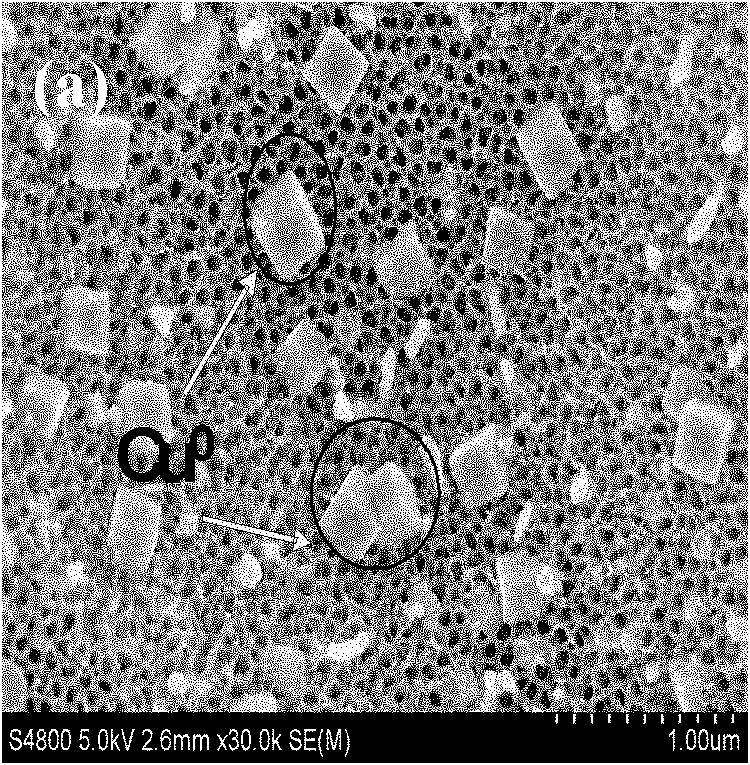

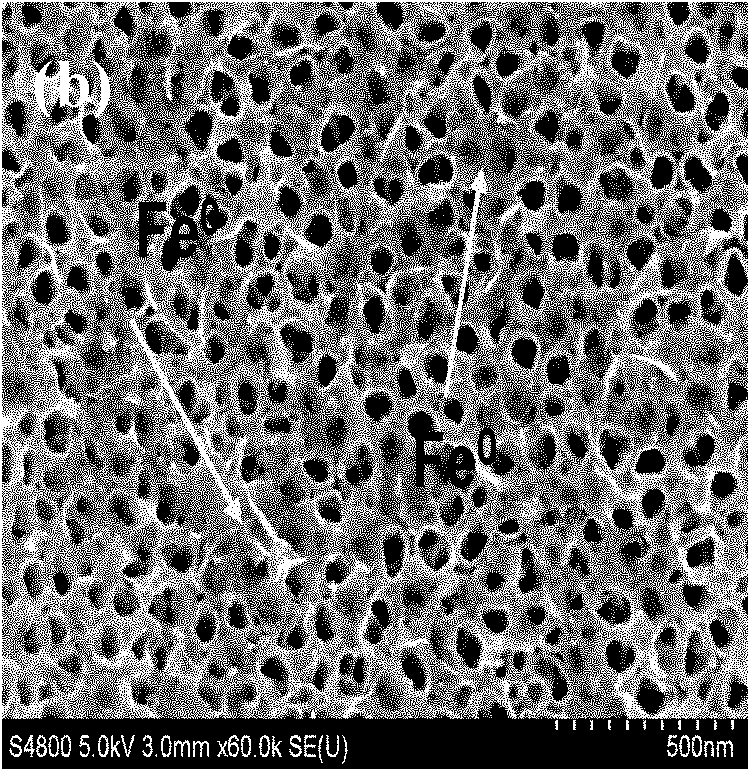

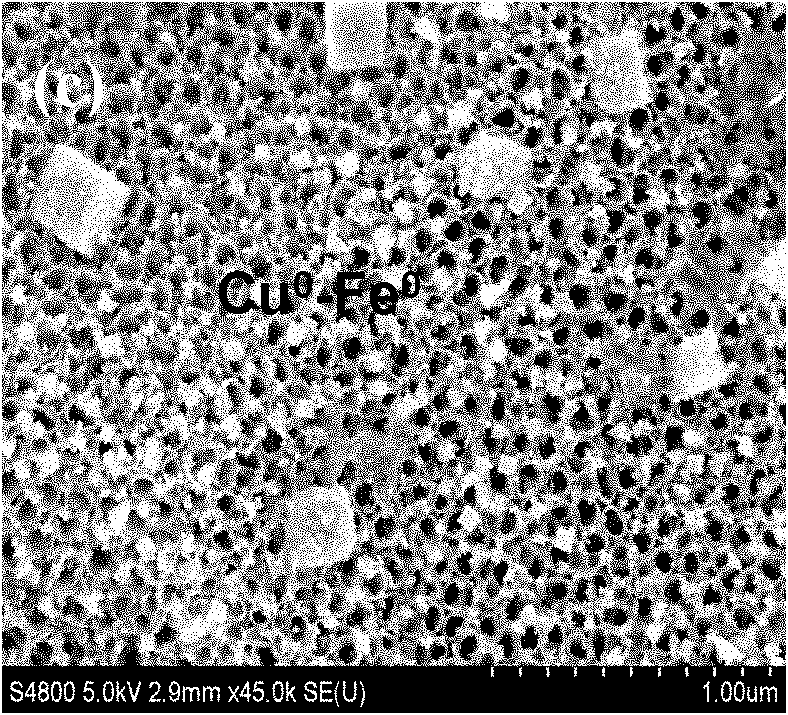

Image

Examples

Embodiment 1

[0021] (1) Grinding the surface of the base material, cleaning it for later use;

[0022] (2) Preparation of organic electrolyte: the electrolyte is prepared by dissolving 0.5-3% hydrofluoric acid, 0.25-0.5% dimethyl sulfoxide or NH4F in ethylene glycol by mass percentage become;

[0023] (3) Under 25-100V DC voltage, using pure titanium or titanium alloy as the anode and platinum sheet as the cathode, electrolytically prepare titanium oxide nanotubes in the electrolyte;

[0024] (4) Calcining the titanium oxide nanotube array prepared above under aerobic conditions at 400°C-500°C for 4-6h to crystallize it into a TiO2 nanotube array.

[0025] (5) Preparation of copper and iron modified titania nanotube arrays:

[0026] ① Place the above TiO2 nanotube array in 5mmol-20mmol CuSO4 solution, and in a standard three-electrode system, electrodeposit copper on the TiO2 nanotube array to obtain a Cu / TiO2 composite nanotube array

[0027] ② Use 5mmol-20mmol FeSO4 as the electroplat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com