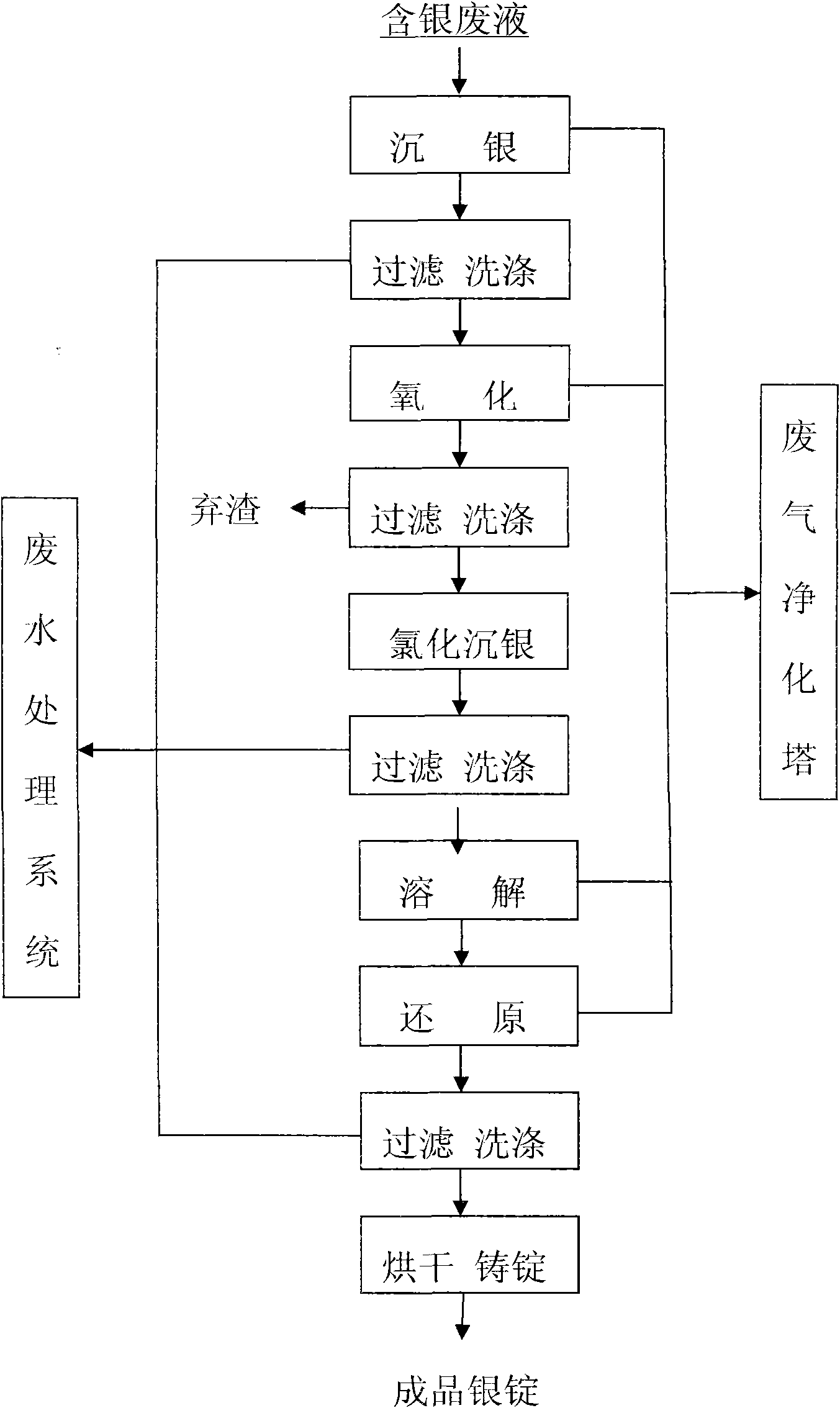

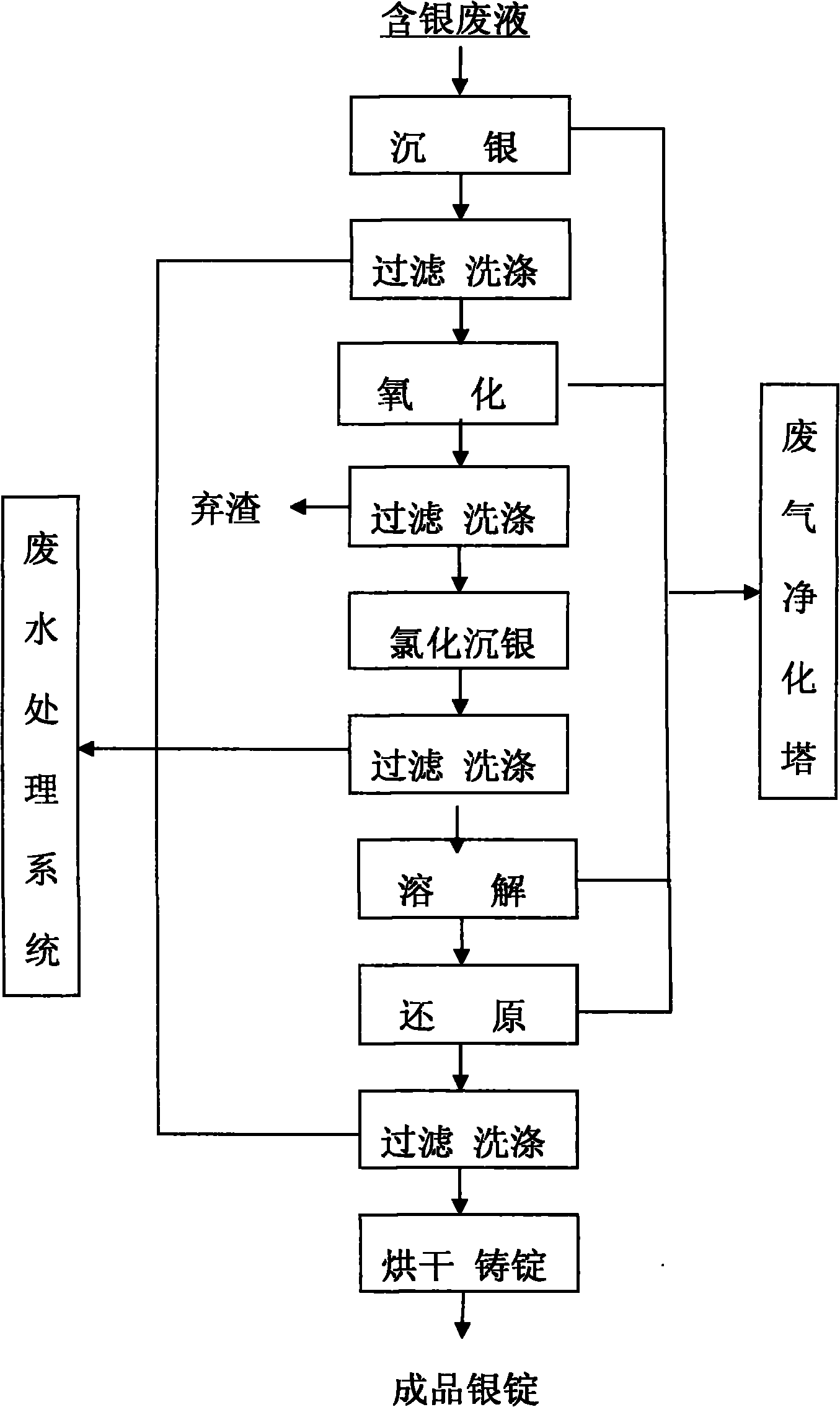

Method for preparing high-purity silver from silver-containing waste liquid

A waste liquid and high-purity technology, applied in chemical instruments and methods, improvement of process efficiency, water/sludge/sewage treatment, etc., can solve the problem of low purity of the final product, achieve high silver recovery rate and good product quality , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1.3L of silver-containing waste liquid, add 2 times the amount of theoretically required silver sinking agent, stir for 30 minutes and then filter. The obtained silver-containing solid is first washed and filtered twice with 1:1 alcohol, and then replaced with hot water at 70°C Washing and filtering are carried out 3 times, and the waste water generated in the process is sent to the waste water treatment system for treatment and discharged after reaching the standard.

[0024] Put it into the reaction kettle after two stages of washing, then use 98% sulfuric acid, and then oxidize it for 30min at a temperature of 120°C, L / S=15:1, and the amount of surfactant added is 1.5% of the silver mud weight. , After the reaction is finished, filter and wash. During the reaction, the reaction kettle maintains negative pressure. The waste gas generated is absorbed and treated by the waste gas purification tower. The filter residue generated is discarded, and the silver-containin...

Embodiment 2

[0028] Take 1.5L of silver-containing waste liquid, add 3 times the amount of theoretically required silver sinking agent, stir for 30 minutes and then filter. The obtained silver-containing solid is first washed and filtered twice with 1:1 alcohol, and then hot water at 70°C is used. Washing and filtering are carried out 3 times, and the waste water generated in the process is sent to the waste water treatment system for treatment and discharged after reaching the standard.

[0029] Put it into the reaction kettle after two stages of washing, then use 60% nitric acid, and then oxidize it for 20min at a temperature of 100°C, L / S=25:1, and the amount of surfactant added is 5% of the silver mud weight. , After the reaction is finished, filter and wash. During the reaction, the reaction kettle maintains negative pressure. The waste gas generated is absorbed and treated by the waste gas purification tower. The filter residue generated is discarded, and the silver-containing solutio...

Embodiment 3

[0033] Take 1.0L of silver-containing waste liquid, add 2.5 times the amount of theoretically required silver sinking agent, stir for 30 minutes and then filter. The obtained silver-containing solid is first washed twice with 1:1 alcohol and filtered, and then replaced with hot water at 70°C Washing and filtering are carried out 3 times, and the waste water generated in the process is sent to the waste water treatment system for treatment and discharged after reaching the standard.

[0034] Put it into the reaction kettle after two stages of washing, then use 25% nitric acid, and then oxidize it for 60min at a temperature of 80°C, L / S=50:1, and the amount of surfactant added is 2.0% of the silver mud weight , After the reaction is finished, filter and wash. During the reaction, the reaction kettle maintains negative pressure. The waste gas generated is absorbed and treated by the waste gas purification tower. The filter residue generated is discarded, and the silver-containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com