Carbonaceous organic material pressurized-gasification solid wet deslagging device and method

A technology for pressurized gasification and organic matter, which is applied in fixed bed gasification, granular/powder fuel gasification, production of combustible gas, etc. Valve wear and other problems, to achieve the effect of suitable slag discharge temperature, elimination of wear and improvement of operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

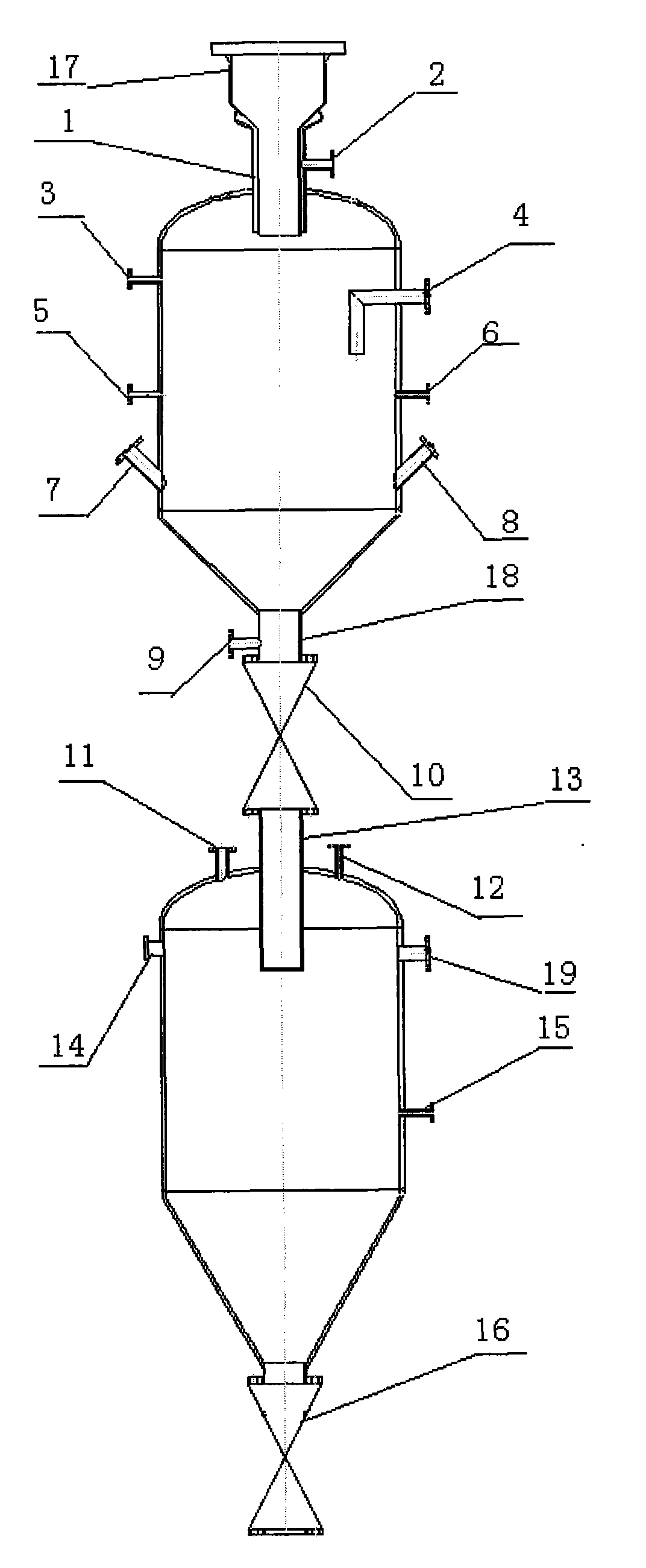

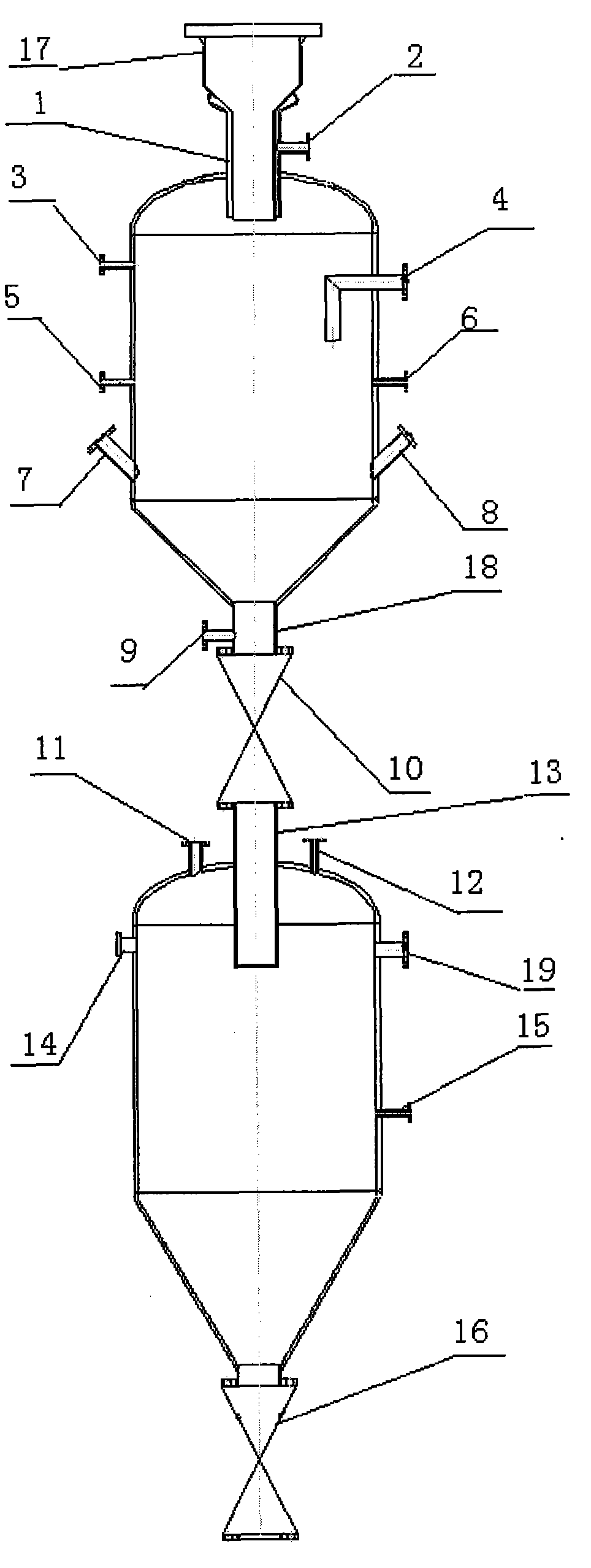

[0025] The slag discharge device is composed of an upper slag hopper and a lower slag hopper. There is a high-temperature ash inlet pipe 17 on the top of the upper slag hopper. There is a jacket pipe 1 outside the high-temperature ash inlet pipe 17. There is water or water on the jacket pipe 1. The low-temperature gas inlet 2, the lower end of the annulus of the jacket pipe 1 is an opening, the upper slag hopper temperature measuring port 6, the upper installation port 3 of the liquid level gauge, the lower installation port 5 of the liquid level gauge and the high pressure water overflow port 4 in the middle of the upper slag hopper , the height of the high-pressure water overflow port 4 is located below the upper installation port 3 of the liquid level gauge, there is a high-pressure water inlet 7 and a circulating water inlet 8 at the lower part of the upper slag hopper, and an upper slag hopper slag discharge pipe 18 is located at the bottom of the upper slag hopper. There ...

Embodiment 2

[0030] The high-temperature ash inlet pipe 17 of the slagging device of the present invention is connected to the slag outlet of the gasifier, and the high-temperature ash discharged from the slag outlet of the gasifier enters the high-temperature ash inlet pipe 17, and the slag from the jacket pipe 1 CO2, entraining ash and slag at a speed of 30m / s, falls into the upper slag hopper, and is cooled to 60°C in contact with high-pressure water. The temperature in the upper slag hopper is controlled by the high-pressure water entering the upper slag hopper high-pressure water inlet 7, and the flow rate is 120t / h, the liquid level of the water in the upper slag hopper is controlled by adjusting the high-pressure water discharged from the high-pressure water overflow port 4. In order to ensure that the ash and slag smoothly fall into the lower slag hopper, the water circulation of 15t / h is discharged from the lower slag hopper circulating water outlet 19 Enter the upper slag hopper ...

Embodiment 3

[0032] The high-temperature ash inlet pipe 17 of the slagging device of the present invention is connected to the slag outlet of the gasifier, and the high-temperature ash discharged from the slag outlet of the gasifier enters the high-temperature ash inlet pipe 17, and the slag from the jacket pipe 1 Water vapor (270°C) entrains ash and slag at a speed of 60m / s and falls into the upper slag hopper, contacts with high-pressure water and is cooled to 80°C, and enters the lower slag hopper through the upper valve 10 of the lower slag hopper with the downward water flow; The temperature in the slag hopper is controlled by the high-pressure water entering the high-pressure water inlet 7 of the upper slag hopper, and the flow rate is 200t / h. The slag falls into the lower slag hopper smoothly, and the 30t / h water discharged from the circulating water outlet 19 of the lower slag hopper circulates through the circulating water inlet 8 and enters the upper slag hopper, forming a downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com