Method for producing water-white hydrogenated rosin

A technology of hydrogenated rosin and production method, applied in the direction of chemical modification of natural resin, can solve problems such as difficulty in practical operation, and achieve the effects of reducing poisoning factors, low abietic acid and low unsaturated double bond content in the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

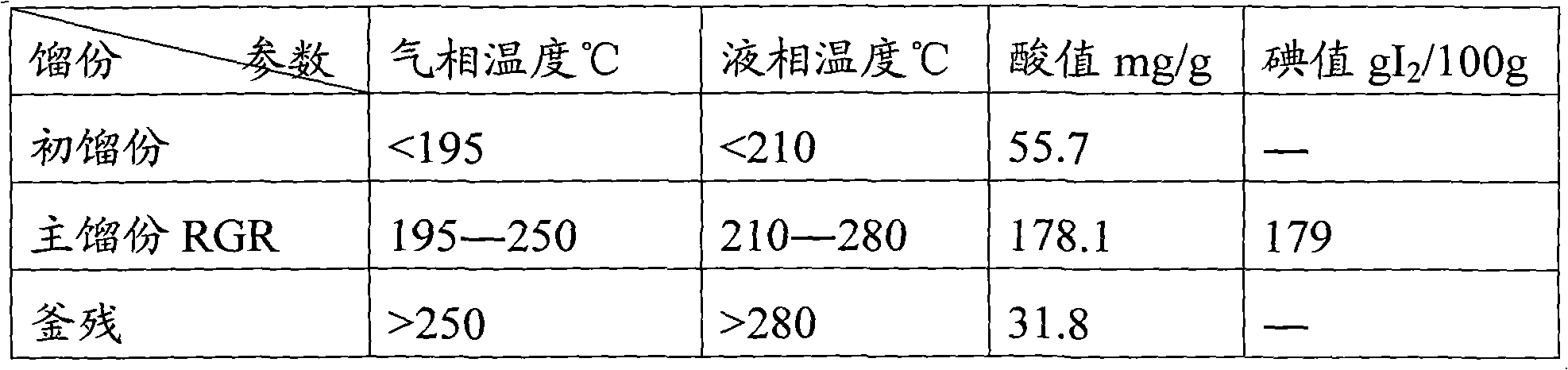

[0052] Distillation and purification: put the rosin with an acid value of 170, an iodine value of 179, a softening point of 76, and a color of first-grade (WW) or extra-grade (X) into the still, and carry out high-vacuum distillation according to the following conditions to obtain the initial Fractions, main fractions, residues.

[0053]

[0054] Hydrogenation by solvent method: add the main fraction RGR and solvent pinane to the melting pot, melt at 100-150°C, and prepare a rosin solution with a concentration of 30-60% by weight, with a flow rate of 600-1000l / h. The amount of material enters the hydrogenation system, and is preheated to 100-200°C and mixed with hydrogen, and then enters the granular palladium-carbon or Raney nickel, the dosage is 1.0m 3 In each batch of fixed-bed reactors, the temperature of each reactor is controlled at 180-260°C, the temperature difference between each section of the reactor is less than 10°C, and the distribution is increasing, the hydr...

Embodiment 2

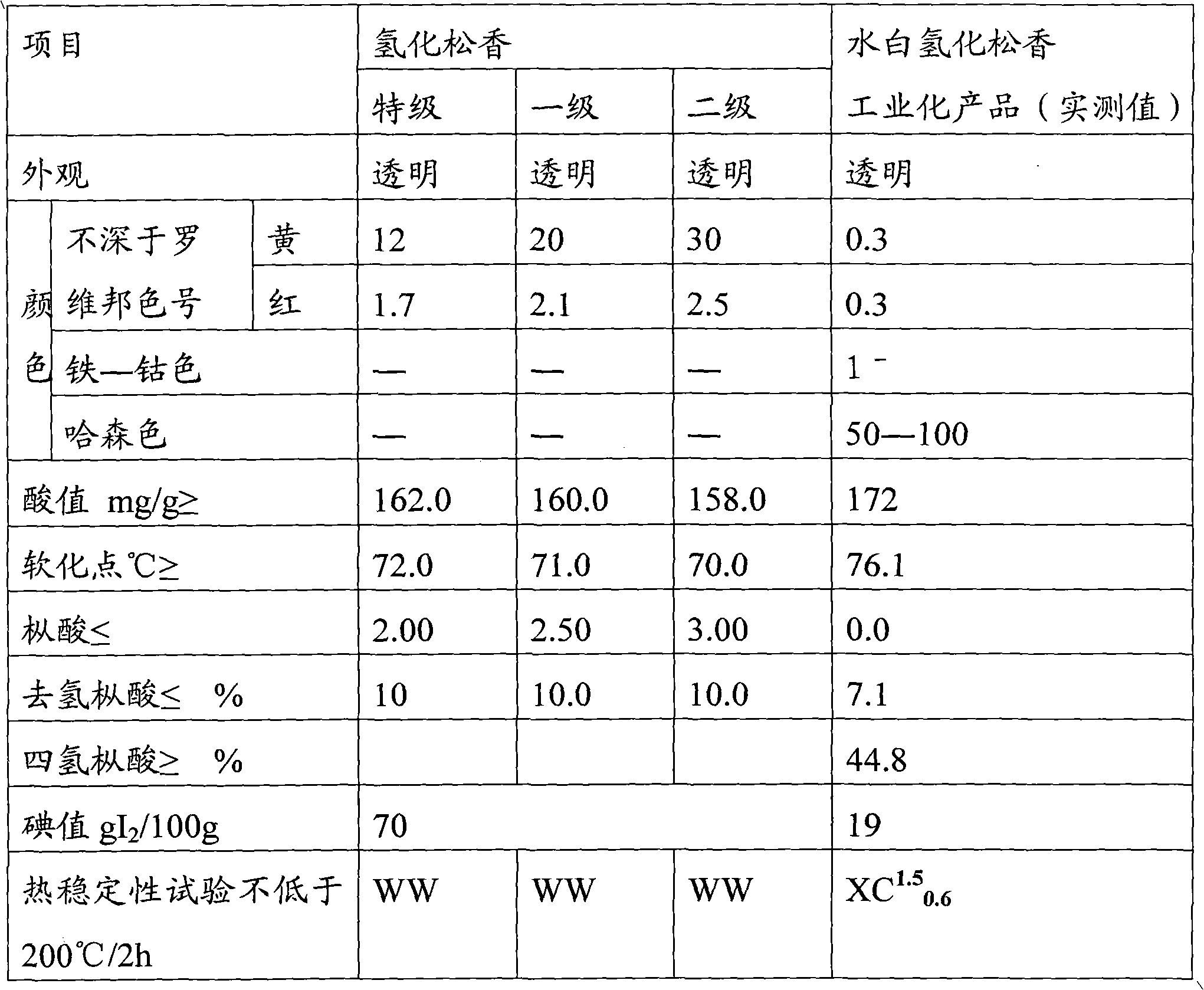

[0057] Add the refined rosin into the dissolving pot, add pinane to adjust the concentration of rosin by weight to 60-80%, the flow rate to 200-600l / h., control the temperature of the reactor to 180-260°C, and the temperature difference of each reactor to be less than 10 °C, increasing distribution, hydrogen pressure between 5.0-15MPa, gas-liquid ratio greater than 2000, reaction time 2-3 hours, and the rest of the process is the same as the embodiment. The product index is: Color: (Luo Weibang) XC 0.5 0.3 , softening point: 77.5°C, acid value: 173mg / g, abietic acid: 0.0%, tetrahydroabietic acid: 56.2%, dehydroabietic acid: 8.0%, iodine value: 16gI 2 / 100g.

Embodiment 3

[0059] The solvent in Example 1 is replaced with turpentine, a mixture of turpentine and pinane, and the temperature of each reactor is mainly controlled at 180-260° C., and all the other processes are the same as in Example 1. The product index is: Color: (Luo Weibang) XC 0.6 0.3 , softening point: 78.9°C, acid value: 172mg / g, abietic acid: 0.0%, tetrahydroabietic acid: 54.2%, dehydroabietic acid: 8.4%, iodine value: 27gI 2 / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com