Medical-grade thermoplastic elastomer industrial production device and production method

A technology for thermoplastic elastomers and production equipment, applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of low hydrogenation degree, poor transparency, high impurity content, etc., and achieve low ash content, hydrogenation The effect of high hydrogen degree and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

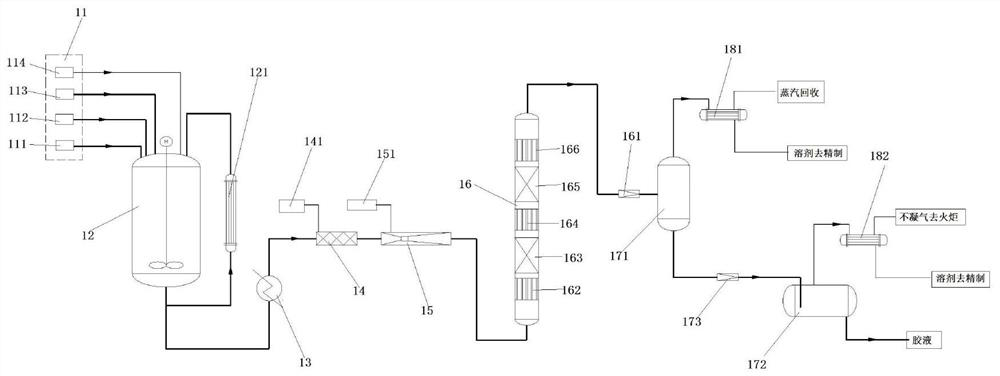

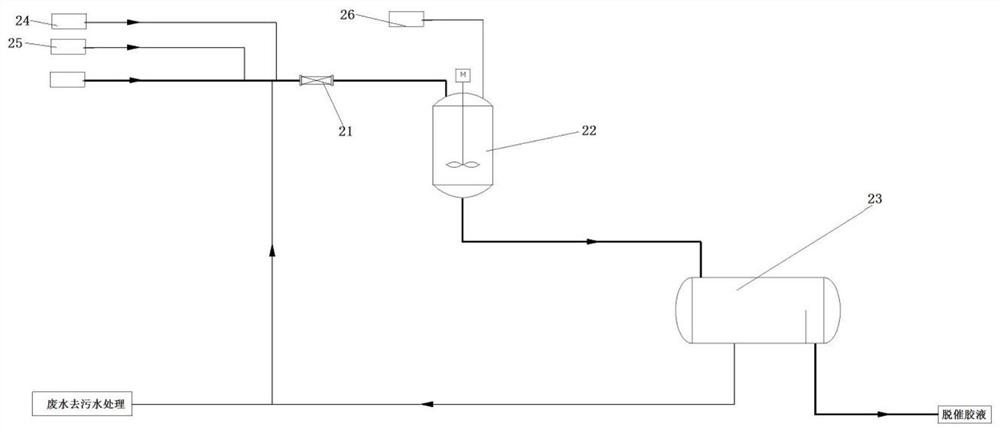

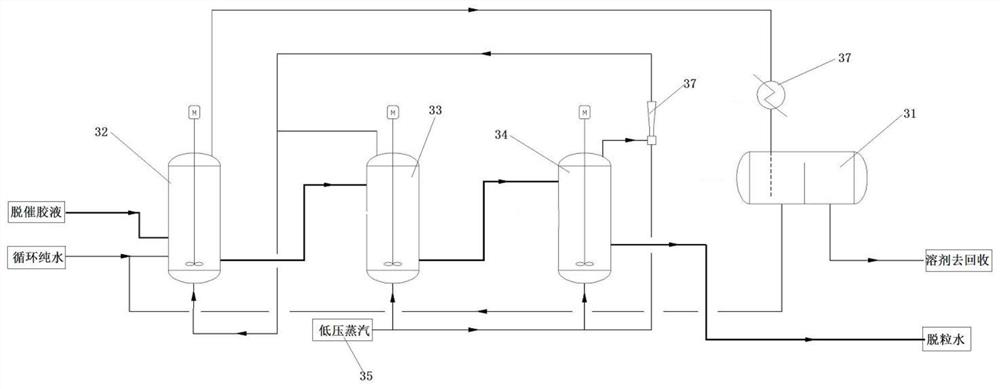

Method used

Image

Examples

Embodiment 1

[0089] First put 900 parts of cyclohexane solvent into the polymerization kettle, then respectively add 15 parts of refined styrene, 70 parts of refined butadiene, and 15 parts of refined styrene into the polymerization kettle for block polymerization reaction, and control the polymerization temperature ≤ 60°C, the initiator uses n-butyllithium (amount of 0.07g / 100g polymer), the activator uses tetrahydrofuran (amount of 0.05g / 100g polymer), and the regulator uses tetramethylethylenediamine (amount of 0.04g / 100g polymer material) to obtain a polymer glue solution with a molecular weight of 170,000 to 200,000; the hydrogenation reaction was carried out using an aged aluminum-titanium catalyst (aluminum-titanium ratio of 5:1), and the addition amount was 0.06mmolTi / 100g polymer, resulting in The product is obtained after subsequent processing.

Embodiment 2

[0091] First put 900 parts of cyclohexane solvent into the polymerization kettle, then respectively add 15 parts of refined styrene, 70 parts of refined butadiene, and 15 parts of refined styrene into the polymerization kettle for block polymerization reaction, and control the polymerization temperature ≤ 60°C, the initiator uses n-butyllithium (amount of 0.07g / 100g polymer), the activator uses tetrahydrofuran (amount of 0.05g / 100g polymer), and the regulator uses ethylene glycol dibutyl ether (amount of 0.05g / 100g polymer material) to obtain a polymer glue solution with a molecular weight of 170,000 to 200,000; the hydrogenation reaction was carried out by using an aged aluminum-titanium catalyst (aluminum-titanium ratio of 4:1), and the addition amount was 0.06mmolTi / 100g polymer. The product is obtained after subsequent processing.

Embodiment 3

[0093] First put 900 parts of cyclohexane solvent into the polymerization kettle, then respectively add 6 parts of refined styrene, 88 parts of refined butadiene, and 6 parts of refined styrene into the polymerization kettle for block polymerization reaction, and control the polymerization temperature ≤ 60°C, the initiator uses n-butyllithium (amount of 0.07g / 100g polymer), the activator uses tetrahydrofuran (amount of 0.05g / 100g polymer), and the regulator uses tetramethylethylenediamine (amount of 0.06g / 100g polymer material) to obtain a polymer glue solution with a molecular weight of 170,000 to 200,000; the hydrogenation reaction was carried out using an aged aluminum-titanium catalyst (aluminum-titanium ratio of 5:1), and the addition amount was 0.08mmolTi / 100g polymer. The product is obtained after subsequent processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com