Method for preparing hydrogenated natural rubber by emulsion method

A technology of natural rubber and emulsion method, which is applied in the field of modified natural rubber and used in the preparation of modified natural rubber, and can solve the problems such as difficulty in obtaining high hydrogenation degree HNR.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

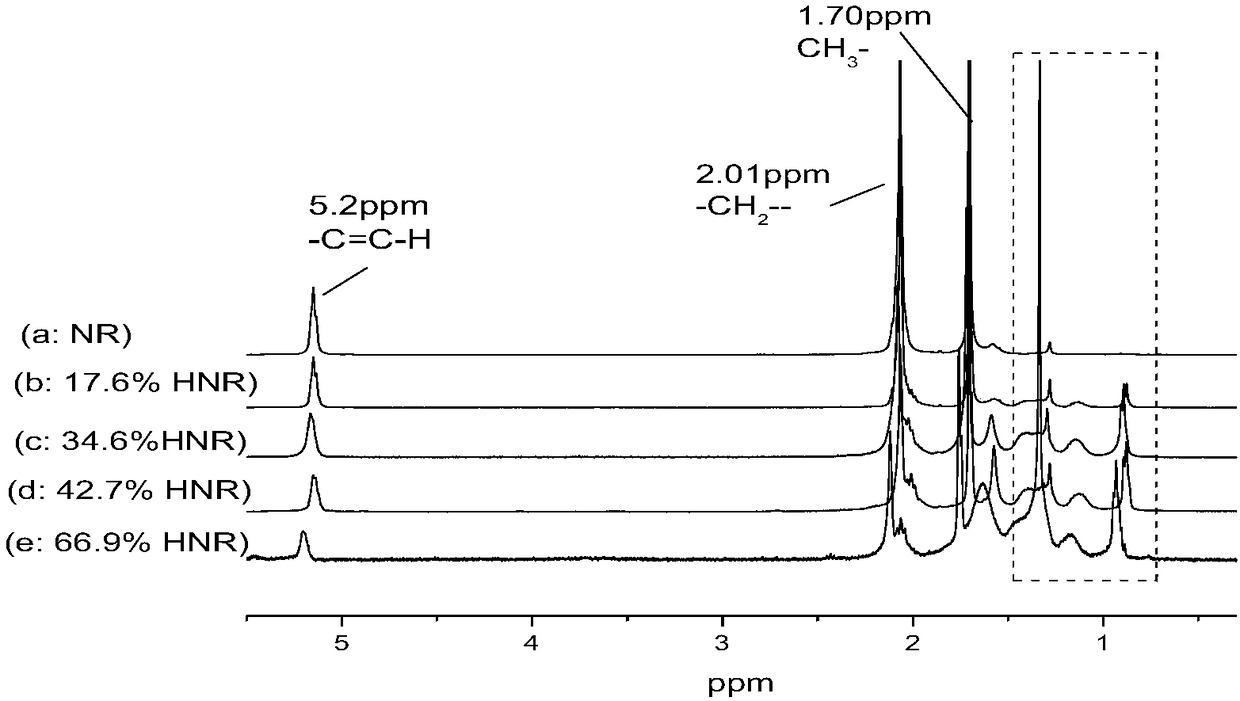

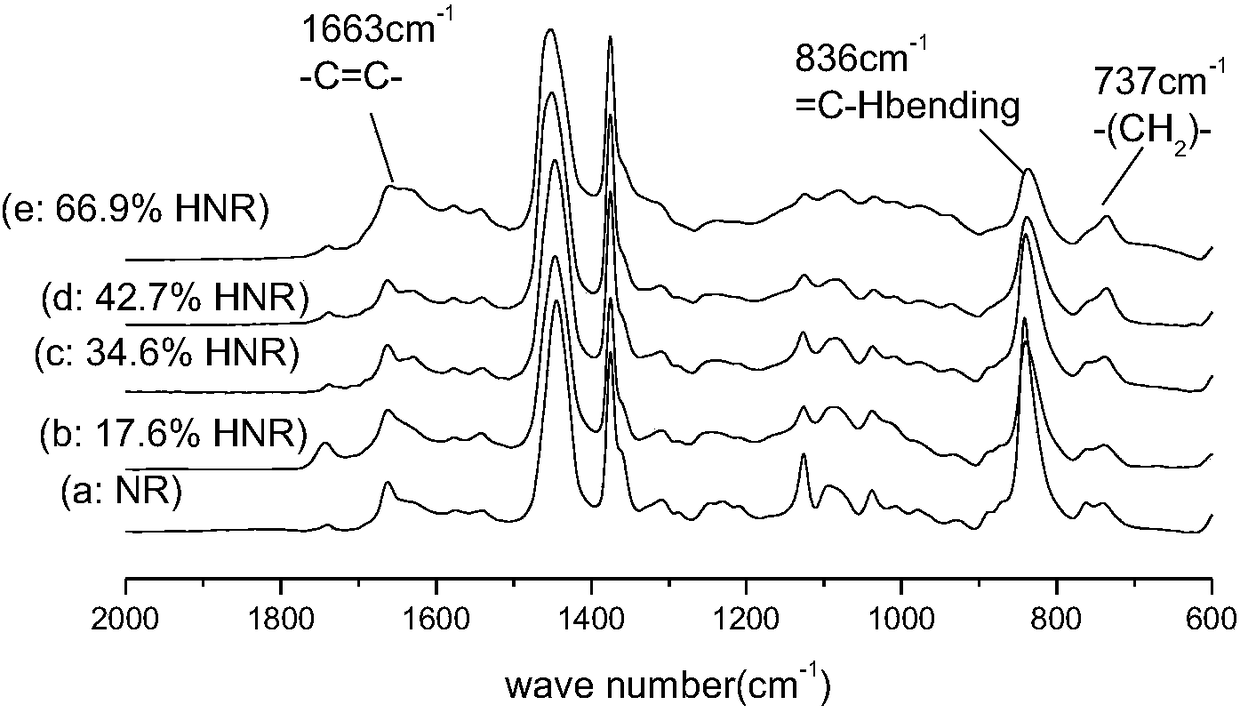

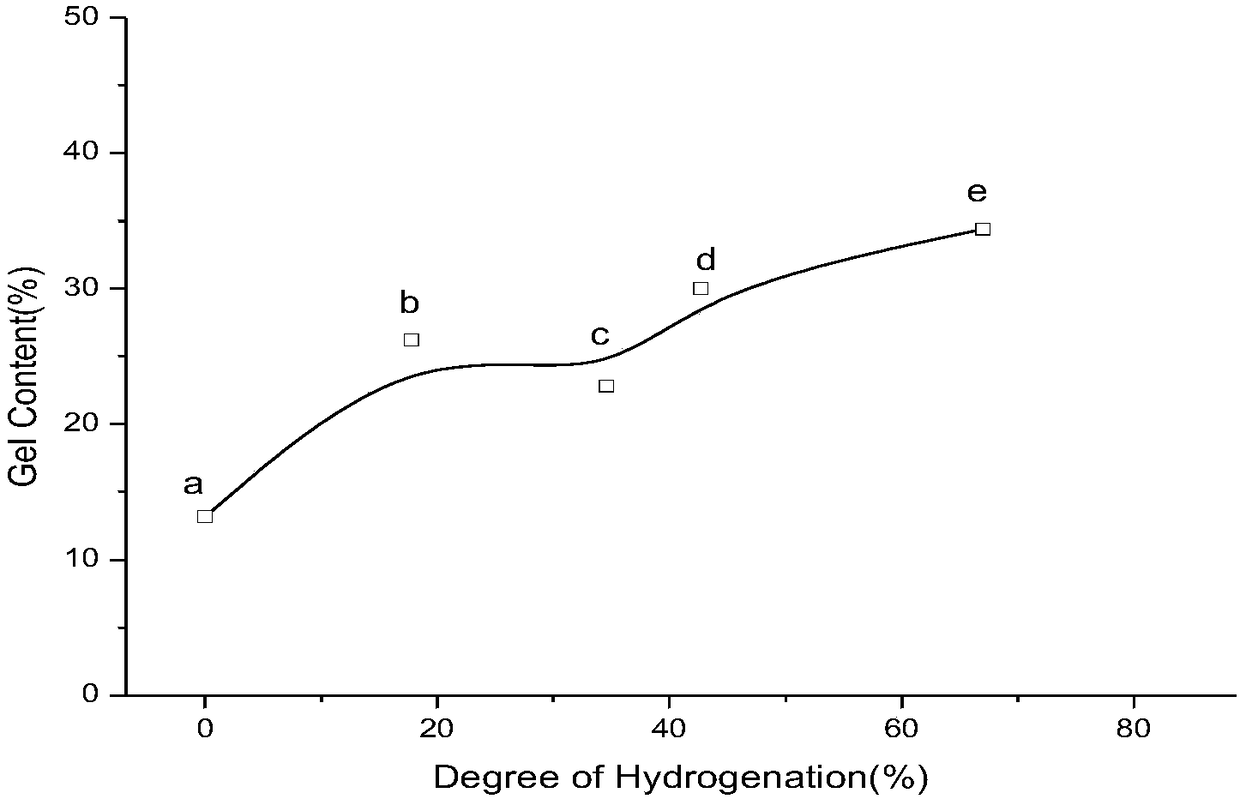

[0037] Add natural rubber latex to a four-neck flask equipped with a condenser, a mechanical stirrer and a thermometer, turn on the mechanical stirring paddle, heat the latex to 55°C, then add hydrazine hydrate; accurately weigh a certain amount of boric acid and dissolve it in deionized water After adding to the reaction system; add an appropriate amount of H at a constant rate 2 o 2 When the reaction system was reached, the reaction was continued for 1 hour after 7 hours of dripping, and the reaction was stopped. C=C:N in NR 2 h 4 :H 2 o 2 The molar ratio is 1:1:1, and the amount of boric acid added is 0.1M. The reactant was taken out and demulsified with 2% calcium chloride aqueous solution, the hydrogenated product was washed with deionized water, and vacuum-dried in an oven at 60°C for 24 hours to obtain HNR raw rubber with a hydrogenation degree of 17.6%.

Embodiment 2

[0039] Add natural rubber latex to a four-neck flask equipped with a condenser, a mechanical stirrer and a thermometer, turn on the mechanical stirring paddle, heat the latex to 55°C, then add hydrazine hydrate; accurately weigh a certain amount of boric acid and dissolve it in deionized water After adding to the reaction system; add an appropriate amount of H at a constant rate 2 o 2 When the reaction system was reached, the reaction was continued for 1 hour after 7 hours of dripping, and the reaction was stopped. C=C:N in NR 2 h 4 :H 2 o 2The molar ratio is 1:2:1.5, and the amount of boric acid added is 0.1M. The reactant was taken out and demulsified with 2% calcium chloride aqueous solution, the hydrogenated product was washed with deionized water, and vacuum-dried in an oven at 60°C for 24 hours to obtain HNR raw rubber with a hydrogenation degree of 34.6%.

Embodiment 3

[0041] Add natural rubber latex to a four-neck flask equipped with a condenser, a mechanical stirrer and a thermometer, turn on the mechanical stirring paddle, heat the latex to 55°C, then add hydrazine hydrate; accurately weigh a certain amount of boric acid and dissolve it in deionized water After adding to the reaction system; add an appropriate amount of H at a constant rate 2 o 2 When the reaction system was reached, the reaction was continued for 1 hour after 7 hours of dripping, and the reaction was stopped. C=C:N in NR 2 h 4 :H 2 o 2 The molar ratio is 1:3:4.5, the amount of boric acid added is 0.1M, the reactant is taken out and demulsified with 2% calcium chloride aqueous solution, the hydrogenated product is washed with deionized water, and vacuum-dried in an oven at 60°C for 24 hours to obtain a hydrogenation degree of 42.7% HNR raw rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com