Method for normal-pressure hydrogenation of unsaturated polymer using magnetic nano ferroferric oxide catalyst

A ferric oxide, magnetic nanotechnology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems affecting performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

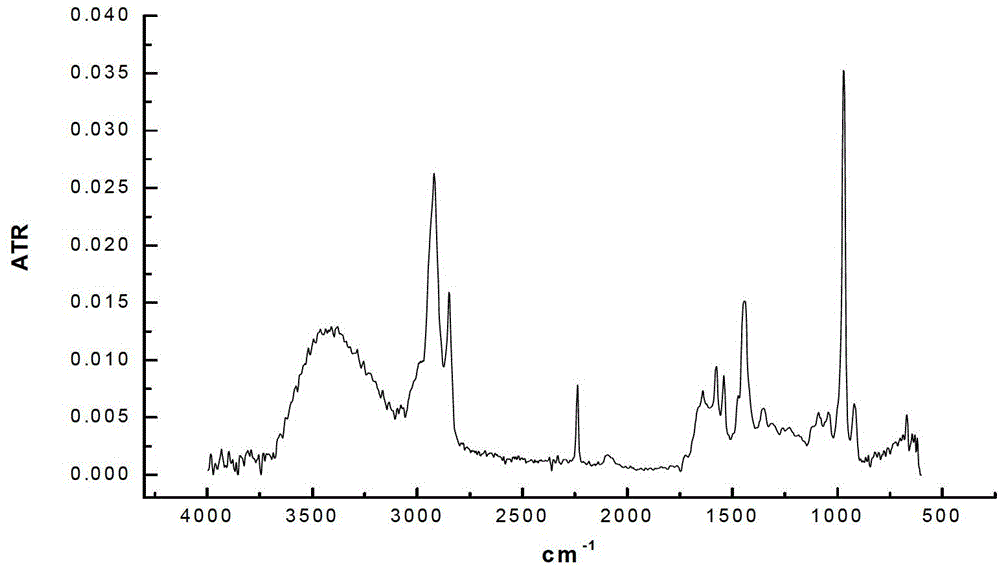

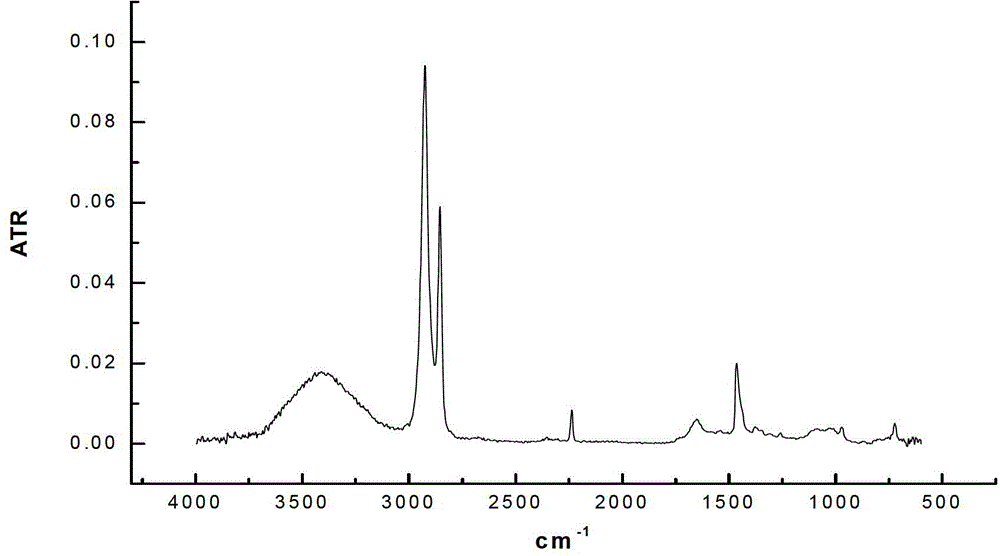

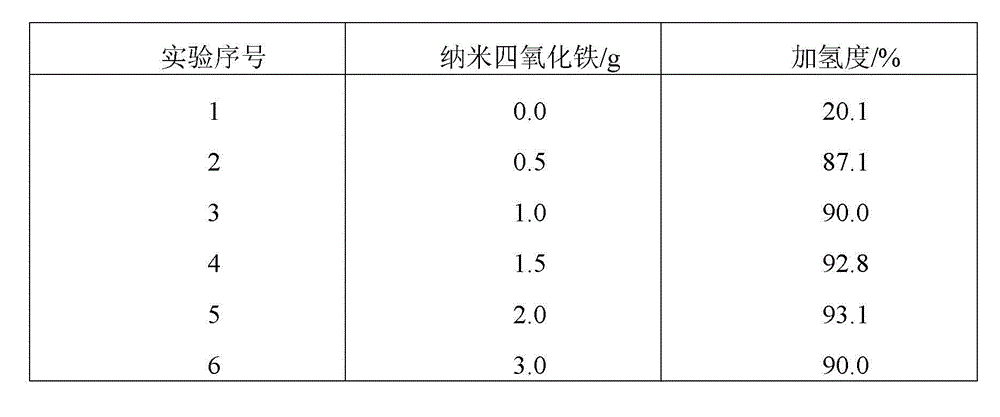

[0022] Add 100mL nitrile latex to the three-neck round bottom flask (system pH is 9.2, solid content is 40%), the reaction temperature is raised to 70°C, keep the temperature constant, add 23.6mL hydrazine hydrate (the molar ratio of hydrazine hydrate to carbon-carbon double bond 15:1), the addition amount of nano ferric oxide is 0.0g, 0.5g, 1.0g, 1.5g, 2.0g, 3.0g respectively, under the stirring speed of 400r / min, under air condition, react for 12h, After the hydrogenation reaction was completed, demulsify with isopropanol, dry, measure the infrared spectrum, and calculate the degree of hydrogenation. The results of the degree of hydrogenation are shown in Table 1.

[0023] Table 1 Effect of the addition amount of nano-Fe3O4 on the degree of hydrogenation

[0024]

Embodiment 2

[0026] Other conditions are the same as in Example 1, the addition of nanometer iron ferric oxide is 2.0g, change the mol ratio of hydrazine hydrate and carbon-carbon double bond, be respectively 3:1, 4:1, 5:1, 8:1,12 :1, 15:1, its hydrogenation degree results are shown in Table 2.

[0027] Table 2 Effect of the molar ratio of hydrazine hydrate to carbon-carbon double bond on the degree of hydrogenation

[0028]

Embodiment 3

[0030] Other conditions are the same as in Example 1, the addition amount of nanometer iron ferric oxide is 2.0g, the addition amount of hydrazine hydrate is 7.9mL (the molar ratio of hydrazine hydrate and carbon-carbon double bond is 5:1), change the stirring speed of the system, They are 200r / min, 300r / min, 400r / min, 500r / min respectively, and the hydrogenation degree results are shown in Table 3.

[0031] Table 3 Effect of stirring speed on degree of hydrogenation

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com