Heterogeneous two-component hydrogenation catalyst, hydrogenated nitrile butadiene rubber, and preparation methods of heterogeneous two-component hydrogenation catalyst and hydrogenated nitrile butadiene rubber

A hydrogenation catalyst and two-component technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of shortening product life cycle, waste of precious metal resources, Accelerate rubber aging and other problems, achieve high selectivity, reduce usage, and promote hydrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

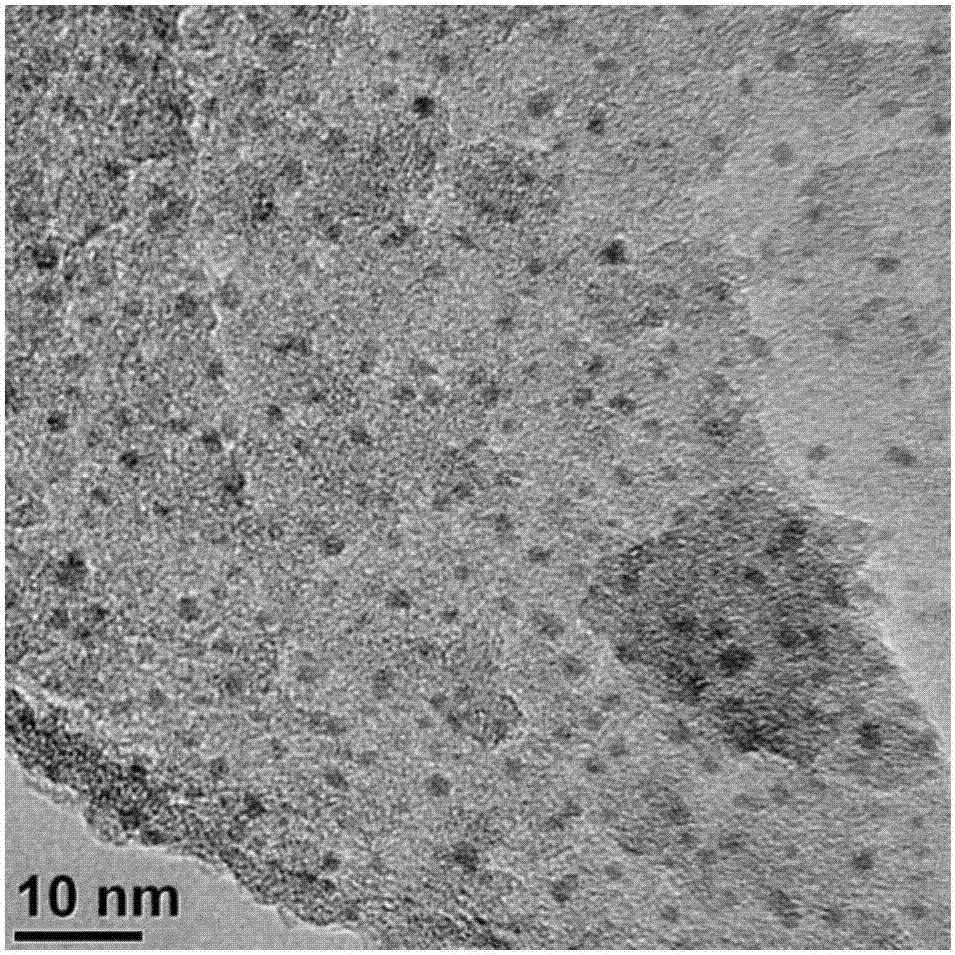

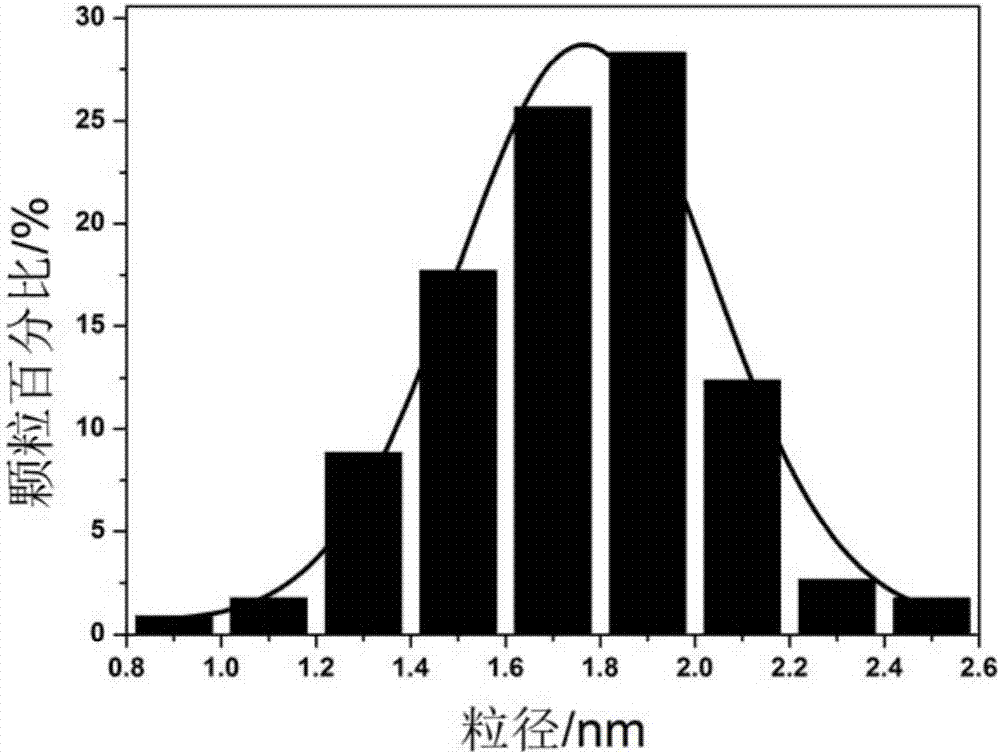

[0052] The specific embodiment of the present invention provides the preparation method of the heterogeneous two-component hydrogenation catalyst, and this preparation method specifically comprises the following steps:

[0053] The modification of SHMs can be carried out according to the following steps, but not limited thereto:

[0054] Take 1g of SHMs and dry at 100°C, cool to room temperature, and disperse in a certain solvent; dissolve a certain amount of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane to prepare a precursor liquid; Body fluid and SHMs dispersion were mixed, stirred at room temperature for 10 min, then transferred to a constant temperature water bath at 80°C for 24 h; after cooling to room temperature, centrifuged, washed with a solvent to remove unreacted substances on the surface of the carrier; after washing, the sample was dispersed in in ethanol, stirred in a 60°C water bath for 8h, cooled to room temperature, separated, and dried in an oven at 100°C t...

Embodiment 1

[0061] This embodiment provides a method for preparing a heterogeneous two-component hydrogenation catalyst, which comprises the following steps:

[0062] N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane amino-modified silica hollow microspheres SHMs, and then, using amino-modified SHMs as a carrier, Pd(OAc) 2 The solution is the precursor liquid of the active component, and Pd is loaded by chemical bonding method, and Zr(C 3 h 7 O) 4 The solution is the precursor liquid of the auxiliary component, and Zr is loaded by the solvent evaporation method to prepare a heterogeneous two-component hydrogenation catalyst Pd-Zr / SHMs with a total loading of 7wt% and a Pd:Zr atomic ratio of 7:1. .

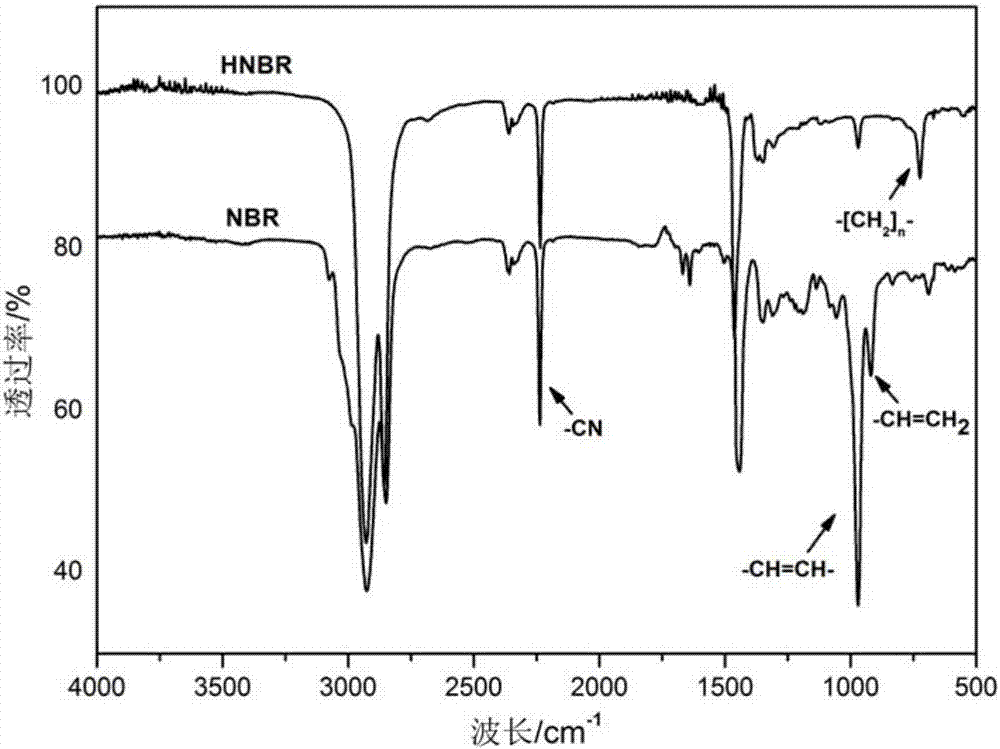

[0063] The present embodiment also provides the preparation method of HNBR, and this preparation method comprises the following steps:

[0064] Dissolve 1g of NBR in 100mL of acetone solvent to obtain glue, take 1g of heterogeneous two-component hydrogenation catalyst Pd-Zr / SHMs into the glue...

Embodiment 2

[0068] This embodiment provides a method for preparing a heterogeneous two-component hydrogenation catalyst, which comprises the following steps:

[0069] N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane amino-modified silica hollow microspheres SHMs, and then, using amino-modified SHMs as a carrier, Pd(OAc) 2 The solution is the precursor liquid of the active component, and Pd is loaded by chemical bonding method, and Zr(C 3 h 7 O) 4 The solution is the precursor liquid of the auxiliary component, and the Zr is loaded by the solvent evaporation method, and finally, after drying, H 2 Reduction and other treatments prepared a heterogeneous two-component hydrogenation catalyst Pd-Zr / SHMs with a total loading of 7wt% and a Pd:Zr atomic ratio of 5:1.

[0070] The preparation method of HNBR is as embodiment 1, and the hydrogenation degree of this method, selectivity and the Pd content that exist in the prepared HNBR are listed in table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com