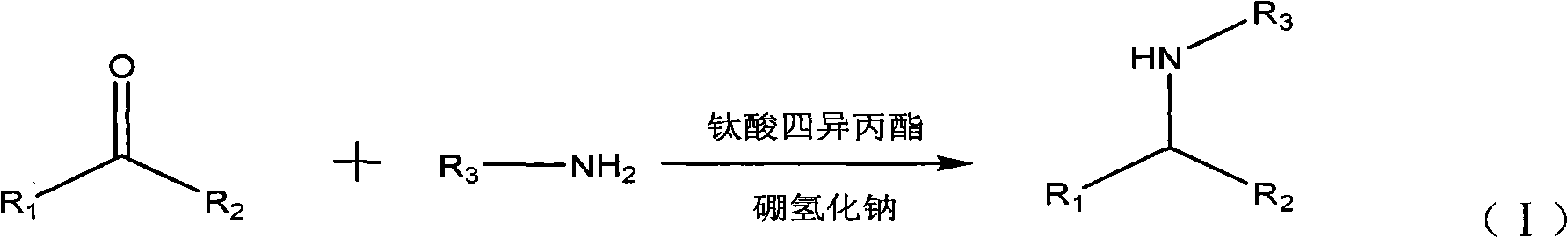

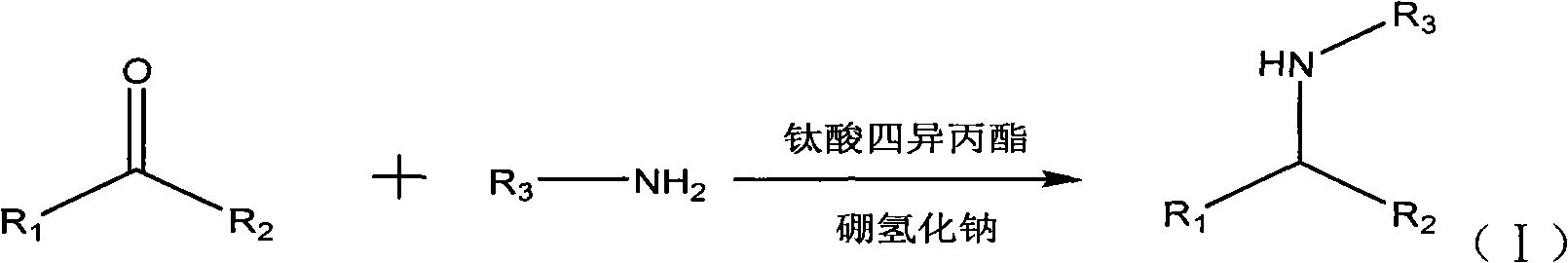

Method for synthesizing aliphatic amine compound

A technology of aliphatic amines and synthesis methods, which is applied in the field of synthesis of aliphatic compounds, can solve the problems of harsh reaction conditions, high risk, and high energy consumption, and achieve the effects of less side reactions, less three-waste emissions, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1. Add 6ml of tetraisopropyl titanate (20mmol), 25ml of anhydrous methanol, and 1.14g of 2-heptanone (10mmol) into a closed reaction vessel with an aeration device, and introduce stable ammonia into the mixed solution. Gas flow, the pressure is normal pressure, the reaction temperature is normal temperature 10 ° C, stirred for 3 hours, stop passing ammonia, the amount of ammonia added is about 100 mmol, then slowly add 0.6 g sodium borohydride (20 mmol) to the reaction system, and then react 6 hours;

[0027] Step 2, adopt silica gel thin-layer chromatography to track reaction, developing agent is ethyl acetate and sherwood oil, and the volume ratio of ethyl acetate and sherwood oil is 3: 7, and iodine is smoked to develop color; Add 15ml of 1mol / L sodium hydroxide solution in the reactor to terminate the reaction;

[0028] Step 3, filter and remove the white solid to obtain the filtrate, extract the filtrate with 30ml of anhydrous ether, and separate the water ph...

Embodiment 2

[0032] Step 1. Add 6ml of tetraisopropyl titanate (20mmol), 25ml of 3mol / L ethanol solution of ammonia, and 1.14g of 2-heptanone (10mmol) into a closed reaction vessel, the pressure is normal pressure, and the reaction temperature is normal temperature 20°C, stirred and reacted for 4 hours, then slowly added 0.6 g of sodium borohydride (20 mmol) to the reaction system, and reacted for another 7 hours;

[0033] Step 2, adopt silica gel thin-layer chromatography to track reaction, developing agent is ethyl acetate and sherwood oil, and the volume ratio of ethyl acetate and sherwood oil is 3: 7, and iodine is smoked to develop color; Add 15ml of 1mol / L sodium hydroxide solution in the reactor to terminate the reaction;

[0034] Step 3, filter and remove the white solid to obtain the filtrate, extract the filtrate with 30ml of anhydrous ether, and separate the water phase; extract the organic phase with 15ml of 1mol / L hydrochloric acid solution, and separate the organic phase; the...

Embodiment 3

[0038] Step 1. Add 6ml of tetraisopropyl titanate (20mmol), 0.55g of propargyl amine (10mmol), 1.14g of 2-heptanone (10mmol), and 30ml of absolute ethanol into a closed reaction vessel at normal pressure , the reaction temperature is normal temperature 20°C, stirred and reacted for 3 hours, then slowly added 0.6g sodium borohydride (20mmol) to the reaction system, and reacted for another 7 hours;

[0039] Step 2, adopt silica gel thin-layer chromatography to track reaction, developing agent is ethyl acetate and sherwood oil, and the volume ratio of ethyl acetate and sherwood oil is 3: 7, and iodine is smoked to develop color; Add 20ml of 1mol / L sodium hydroxide solution to the reactor to terminate the reaction;

[0040] Step 3, filter and remove the white solid to obtain the filtrate, extract the filtrate with 30ml of anhydrous ether, and divide the aqueous phase; extract the organic phase with 20ml of 1mol / L hydrochloric acid solution, and divide the organic phase; the aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com