Novel crystalline silicon solar cell and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as reducing surface recombination rate, limiting battery open circuit voltage, and reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

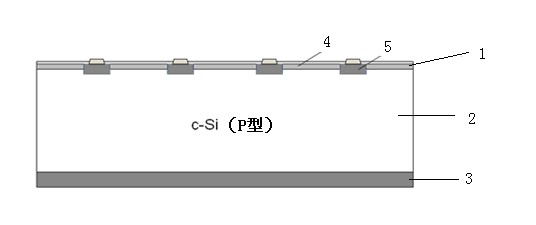

[0027] This invention is a design plan for the transformation efficiency of crystal silicon solar batteries to obtain the largest solar cell conversion efficiency.The matrix of the solar cell can use a light mixed single crystal silicon wafer with a resistance of 0.1 ~ 10 ω ?? CM is a polysilicon silicon wafer.The front surface of the substrate has a selective transmitting pole structure. This structure is a heavy diffusion under the metal grille line, and the area between the grid lines is lightly spread to obtain a low contact resistance.During the diffusion, the light diffusion zone and the heavy diffusion area have formed a conductivity that is opposite to the substrate (for example, the matrix is P type, the corresponding heavy diffusion zone and the light diffusion zone are N -type, and vice versa).A layer of reducing membrane (such as: silicon nitride or silicon dioxide, or silicon oxide and silica nitride stacks) are deposited on the front surface, and only the heavy diffu...

Embodiment 2

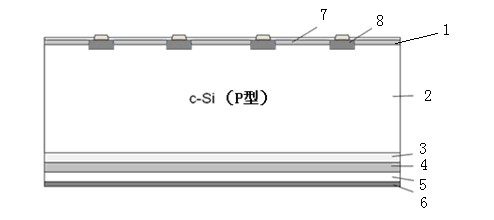

[0030] Figure 4 The solar battery structure diagram of the implementation method.A photovoltaic battery that can convert solar energy into electrical energy provided by this embodiment. The structure is as follows: a kind of conductive crystal silicon matrix, the matrix can be single crystal silicon wafers or polycrystalline silicon wafers.The front surface of the matrix has a transmitting polar structure. This structure is expanded under the metal grille line, and the regional expansion between the grid lines is lightly expanded.The first layer of reduction of the anticipation and a set of metal conductive electrode; there is a heterogeneous structure on the back of the substrate. This structure includes: the first layer covers the album of hydrococcinimum silicon (A-SI: H) membrane covering the entire back of the substrate.; The first layer adopts a doped agent with the same type of conductivity type for heavy doping of hydrogenated amorphous silicon (A-SI: H) membrane; the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com