Improved process for smelting metallic titanium by electro-deoxidation method

A metal titanium and electro-deoxidation technology, applied in the fields of metallurgy and electrochemistry, can solve problems such as prolonging production time, decreasing production efficiency, and increasing resistance to deep deoxidation, and achieves the effects of improving current efficiency, shortening reaction time, and simple process structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Take 100g of titanium dioxide fine powder (≥99%), add 10g of 5% polyvinyl alcohol (PVA) aqueous solution, stir evenly, press it into Φ20mm*5mm discs in batches under 15Mpa molding pressure, process a Φ3mm hole in the center, and shape The finished cathode sheet was dehydrated at 100° C. for 24 hours, and sintered at 1300° C. for 4 hours in a hydrogen atmosphere to obtain a cathode sheet with a porosity of 19%. The sintered cathode sheets are connected in series with resistance wires to form cathode rods, the total amount of titanium dioxide cathode sheets is about 100g, and the distance between cathode and anode is 200mm. Protective gas argon flow rate is set to 5L / min, molten salt CaCl 2 The depth is 140mm, and the electrolysis is carried out at 950°C for 48h. The product is gray-black in color, and there is a small amount of gray dense layer inside. After testing, it is mainly intermediate products TiO, Ti 2 O ingredients. The product was crushed, pickled and clean...

example 2

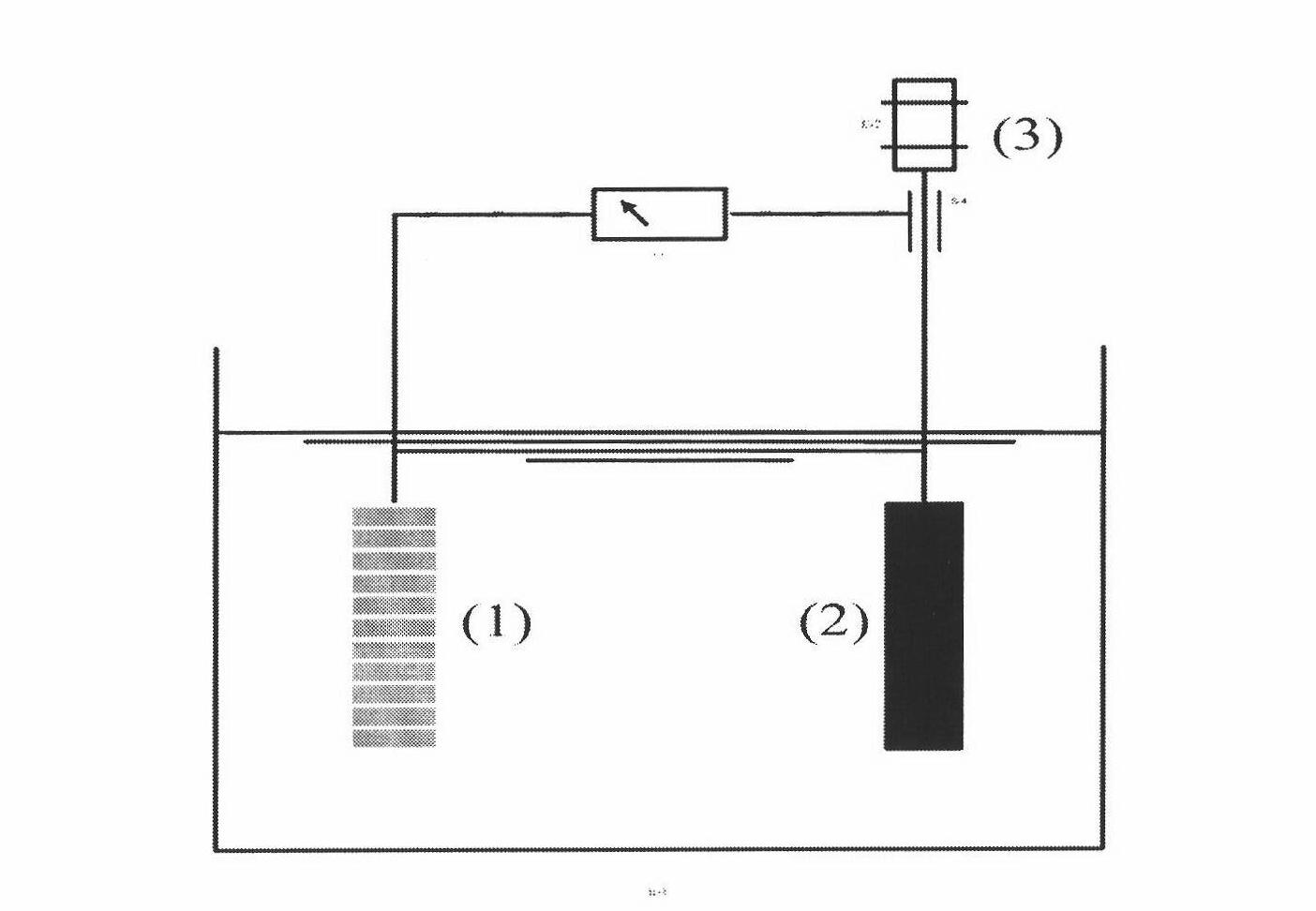

[0021] Take 100g of titanium dioxide fine powder (≥99%), add 25g of 10% polyvinyl alcohol (PVA) aqueous solution, stir evenly, press it into Φ20mm*5mm discs in batches under 15Mpa molding pressure, process a Φ3mm hole in the center, and shape The finished cathode sheet was dehydrated at 130° C. for 48 hours, and sintered at 1100° C. for 4 hours in a hydrogen atmosphere to obtain a cathode sheet with a porosity of 25%. The sintered cathode sheets are connected in series with resistance wires to form cathode rods, the cathode rods are wrapped with stainless steel mesh, and the amount of titanium dioxide added is about 100g / group. The distance between cathode and anode is 200mm, the anode rod is connected to the motor through the transmission shaft, the speed is set at 120rpm, and the electrode configuration is as follows: figure 1 shown. Argon flow is set to 5L / min, molten salt CaCl 2 The control depth is 140mm, and the electrolysis is carried out at 950°C for 36h. In additio...

example 3

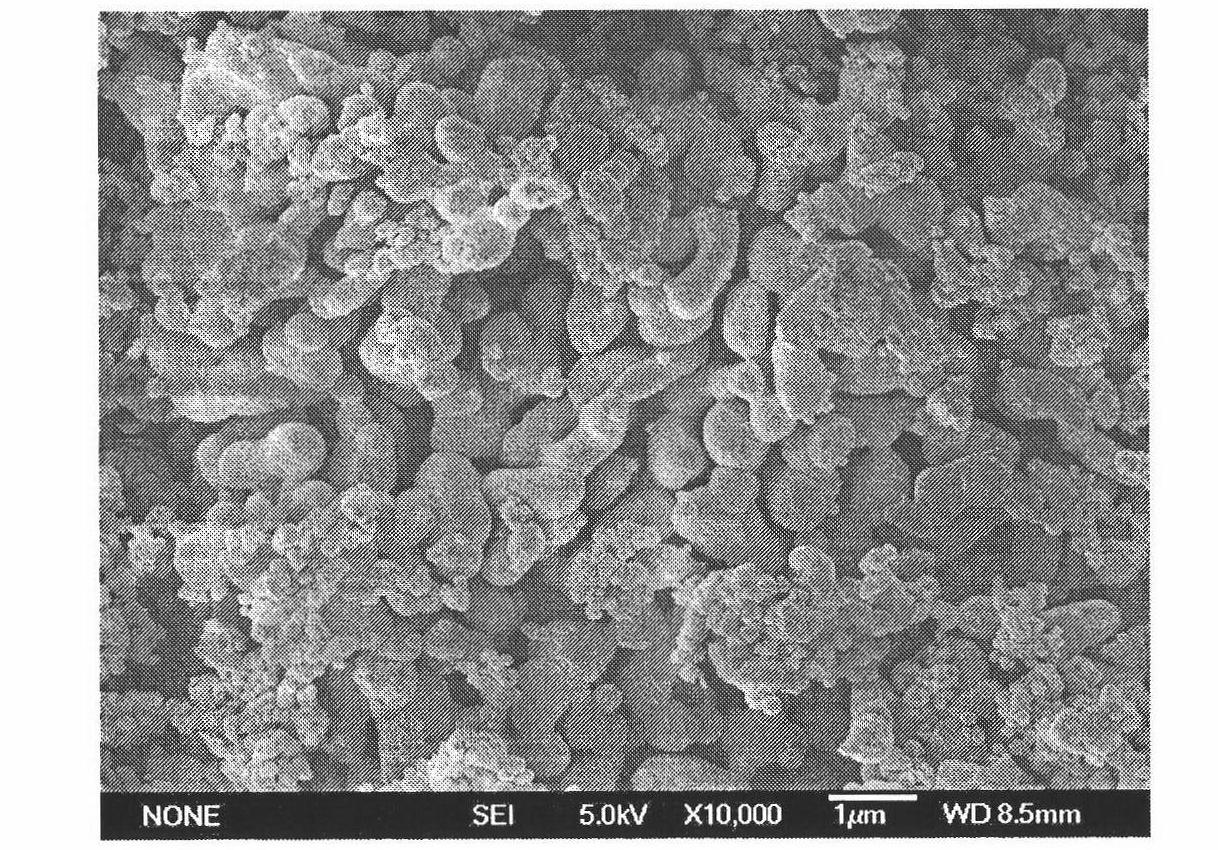

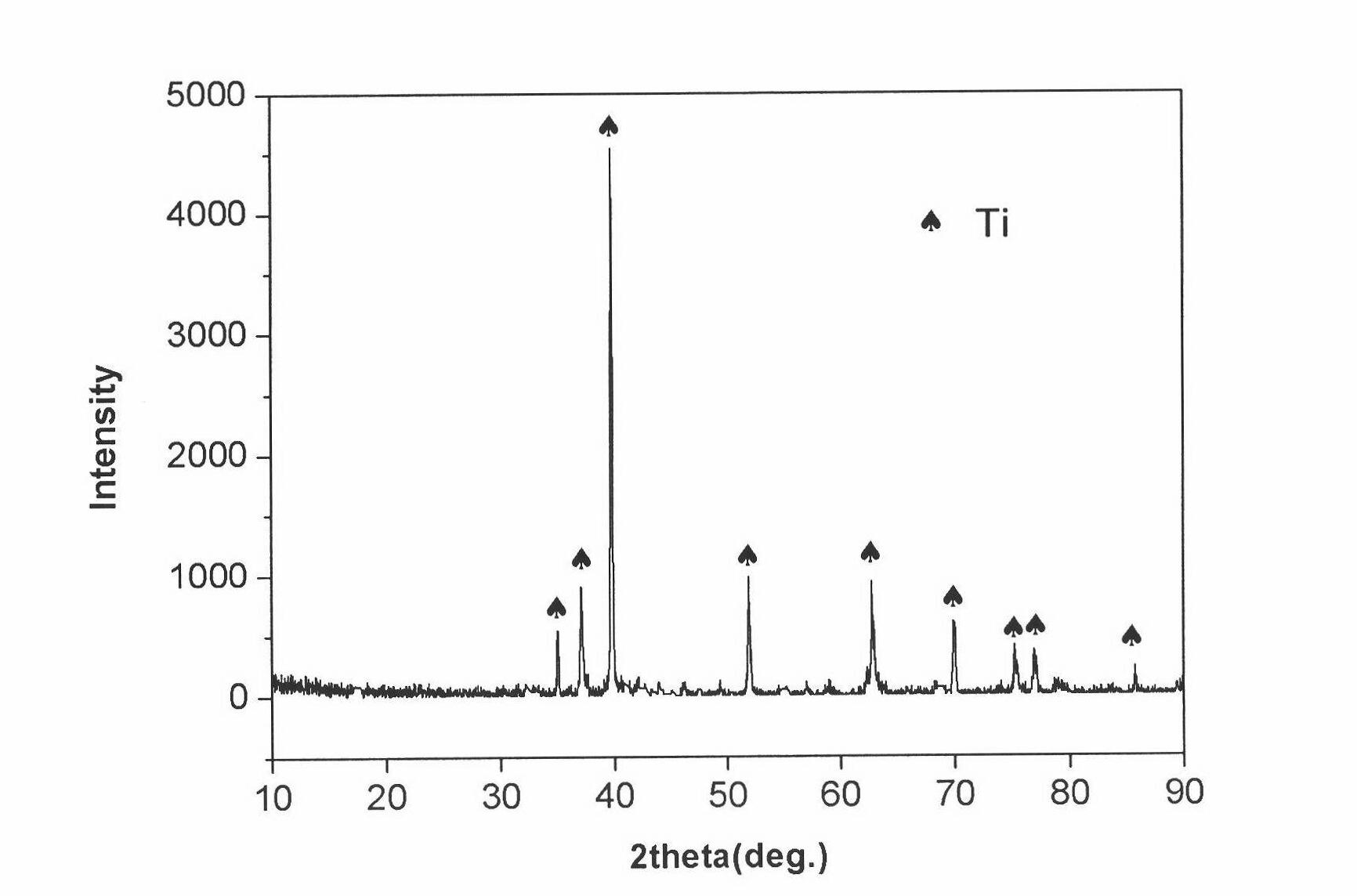

[0023] Take 100g of titanium dioxide fine powder (≥99%), mix with 10g of activated carbon powder (100-200 mesh), mix evenly, add 20g of 15% polyvinyl alcohol (PVA) aqueous solution, stir evenly, and batch under 20Mpa molding pressure Pressed into a disc body of Φ20mm*5mm, with a Φ3mm opening in the center, the formed cathode sheet was dehydrated at 120°C for 36 hours, and sintered at 1200°C for 4 hours in a hydrogen atmosphere to obtain a cathode sheet with a porosity of 35%. After sintering, the cathode sheet The SEM electron microscope topography of the film is shown in figure 2 . Connect the sintered cathode sheets in series with resistance wires to form a cathode rod. The total amount of titanium dioxide cathode sheets is about 100g, and the distance between cathode and anode is 200mm. The anode rod is connected to the motor through the transmission shaft, and the speed is set at 120rpm. figure 1 shown. Protective gas argon flow rate is set to 5L / min, molten salt CaCl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com