Smelting and separating method of noble lead

A separation method and precious lead technology, which is applied in the field of precious lead smelting and separation, can solve the problems of sulfur waste gas and waste water polluting the environment, difficulties in comprehensive recovery, etc., and achieve the goals of increasing direct yield, improving the production environment, and shortening the oxidation blowing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

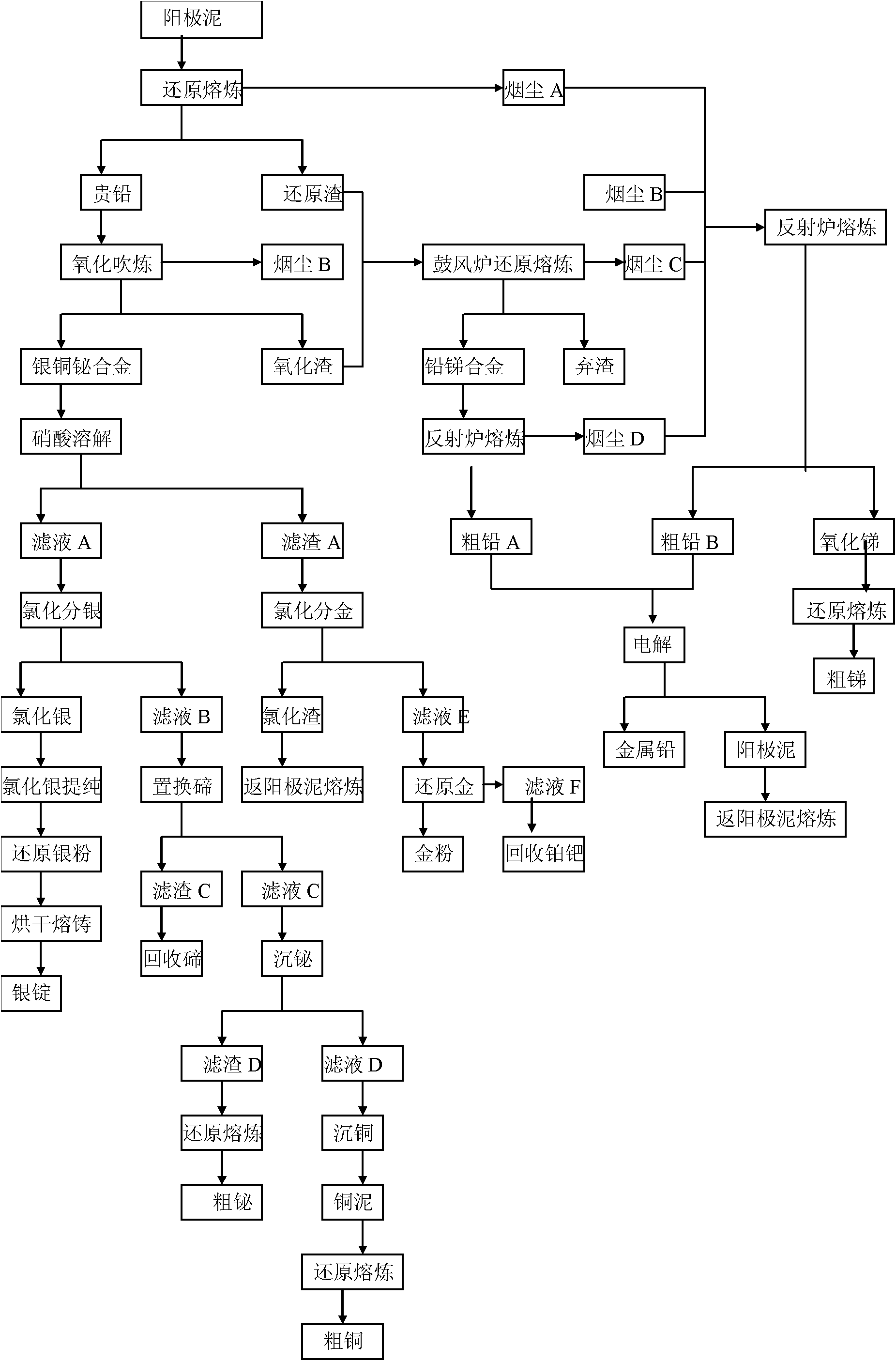

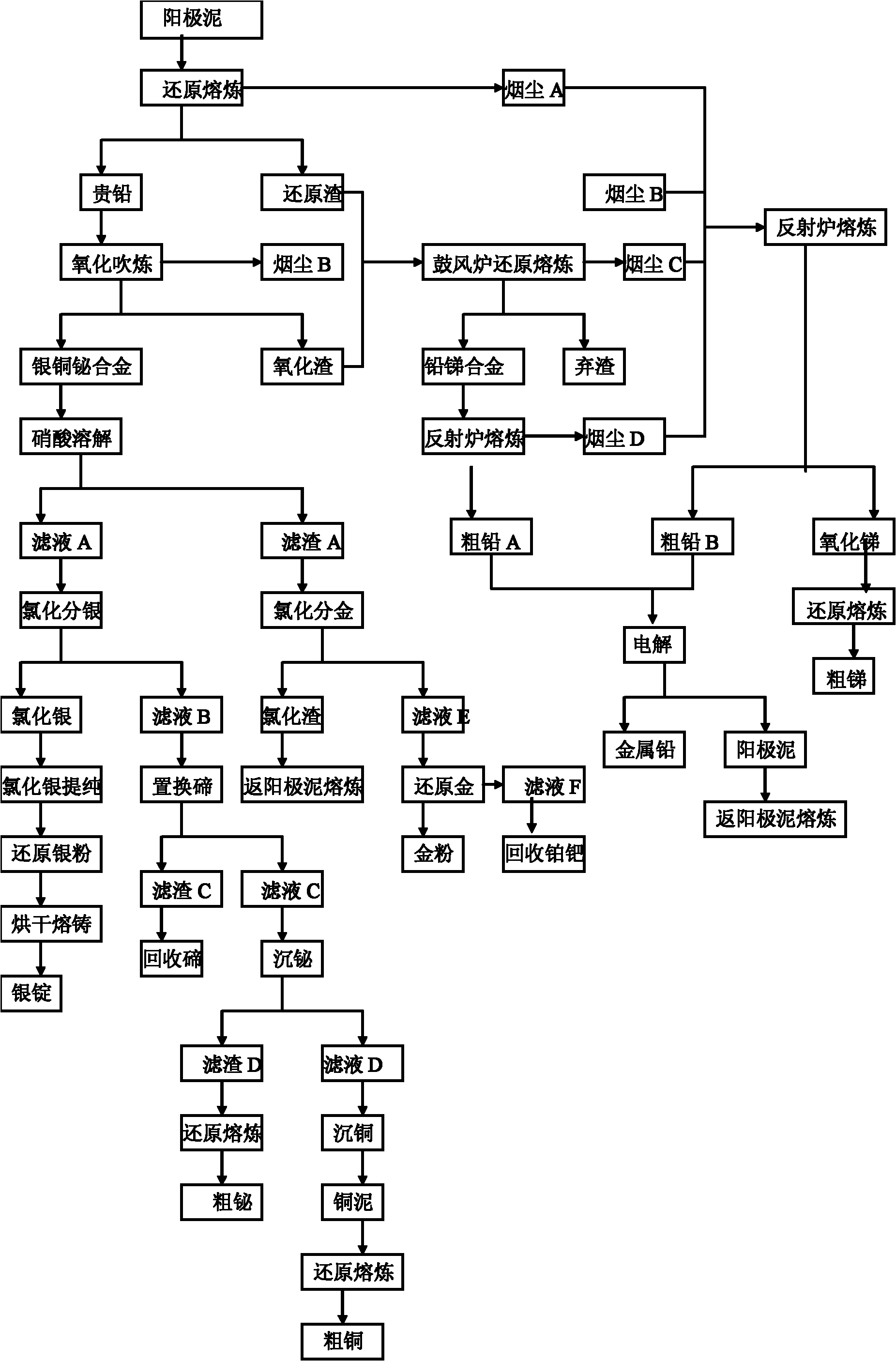

Method used

Image

Examples

Embodiment 1

[0015] Smelting of copper anode slime

[0016] (1) The composition of copper anode slime is about: 0.5-1wt% gold, 10-15wt% silver, 10wt% copper, 20-25wt% lead, 15-20wt% antimony, 5wt% bismuth, and <5wt% silicon dioxide , selenium<0.3wt%, tellurium 0.5wt%, water 15wt%. During smelting, 8-15wt% of sodium carbonate, 3-5wt% of fluorite powder, 6-10wt% of pulverized coal, and 2-4wt% of iron filings are added to the total weight of the copper anode slime.

[0017] (2) Put evenly proportioned copper anode slime into the smelting furnace, reduce and smelt at 1000-1200°C to form precious lead rich in gold and silver, and reduction slag and soot A mainly containing silicon dioxide, lead and antimony. The main components of noble lead are: gold 0.8-1.6wt%, silver 15-25wt%, lead 35wt%, antimony 10-20wt%, copper 18wt%, bismuth 8wt%, tellurium 0.8wt%, reduction slag and soot A The lead and antimony smelting system recovers lead and antimony.

[0018] (3) Add the noble lead produced in st...

Embodiment 2

[0026] Embodiment 2, the smelting of lead anode slime

[0027] (1) The composition of lead anode slime is about: gold 0.05wt%, silver 5-10wt%, copper 3-5wt%, lead 20-25wt%, antimony 10-30wt%, bismuth 5-10wt%, tellurium 0.1-0.5 wt%, silicon dioxide <5wt%, water 20wt%. During smelting, 3-5wt% of sodium carbonate and 2-3wt% of pulverized coal are added to the total weight of the lead anode slime.

[0028] (2) Add uniformly proportioned lead anode slime into the smelting furnace, reduce and smelt at 1000-1150°C, and produce noble lead. The main components are: gold 0.1wt%, silver 10-20wt%, copper 5-10wt% %, lead 30-40wt%, antimony 20-40wt%, bismuth 10-20wt%, tellurium 0.2-1wt%, and also produce reduction slag and soot A mainly lead-antimony and silicon dioxide.

[0029] (3) Add the precious lead produced in step (2) into the converter, and moderately oxidize and blow at 700-900°C to remove the antimony-lead until the silver-copper-bismuth alloy containing gold, silver, copper, b...

Embodiment 3

[0037] Embodiment 3: the smelting of noble lead

[0038] (1) The total processing of precious lead raw materials is 15 tons, and its composition is approximately: silver 5wt%, copper 9wt%, lead 53wt%, antimony 18wt%, bismuth 14.5wt%, gold 0.2wt%. Add noble lead into the converter, oxidize and blow antimony lead at 700-1000°C to produce silver-copper-bismuth alloy with the sum of lead and antimony content less than 5%, gold, silver, copper and bismuth are basically enriched in silver-copper-bismuth alloy Antimony enters oxide slag and soot B.

[0039](2) the silver-copper-bismuth alloy produced by step (1) is dissolved with nitric acid, wherein the silver-copper-bismuth dissolves into the solution substantially, and the solution is filtered to obtain filtrate A and filter residue A, and filtrate A adds 25g / L sodium chloride solution to precipitate Silver, filtered to obtain filtrate B and silver chloride, the silver chloride is washed and purified with boiling dilute acid wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com