Combined titanium alloy hammer

A titanium alloy and combined technology, applied in the field of combined titanium alloy hammers, can solve the problems of small differences, inability to achieve hardness differentiation, failure to meet requirements, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

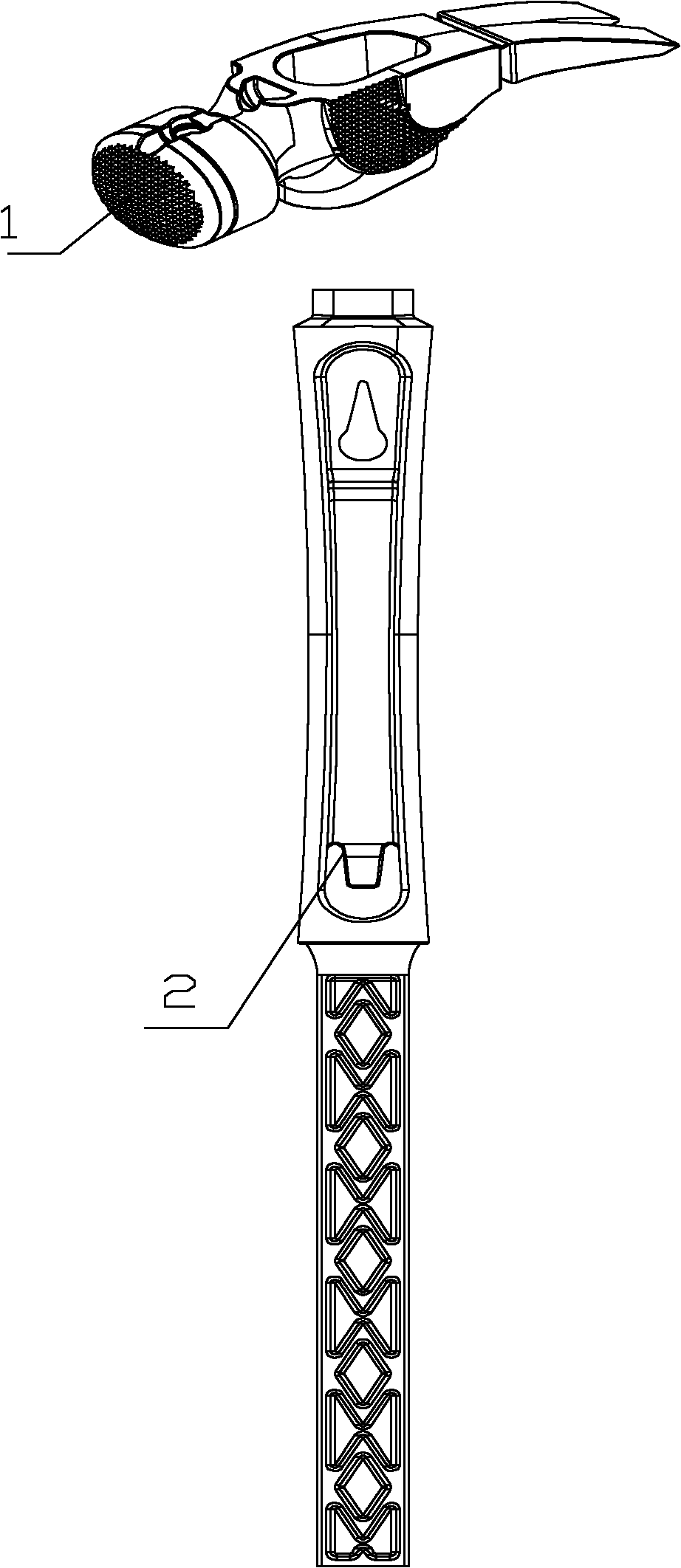

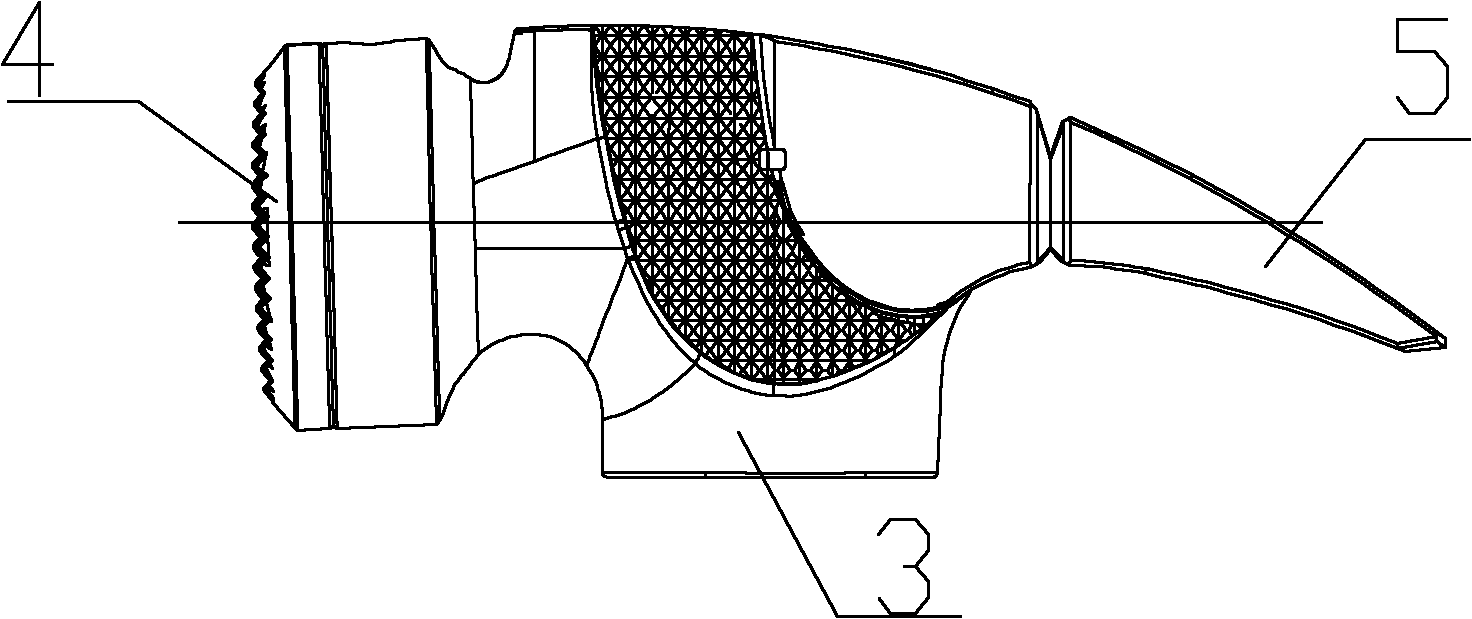

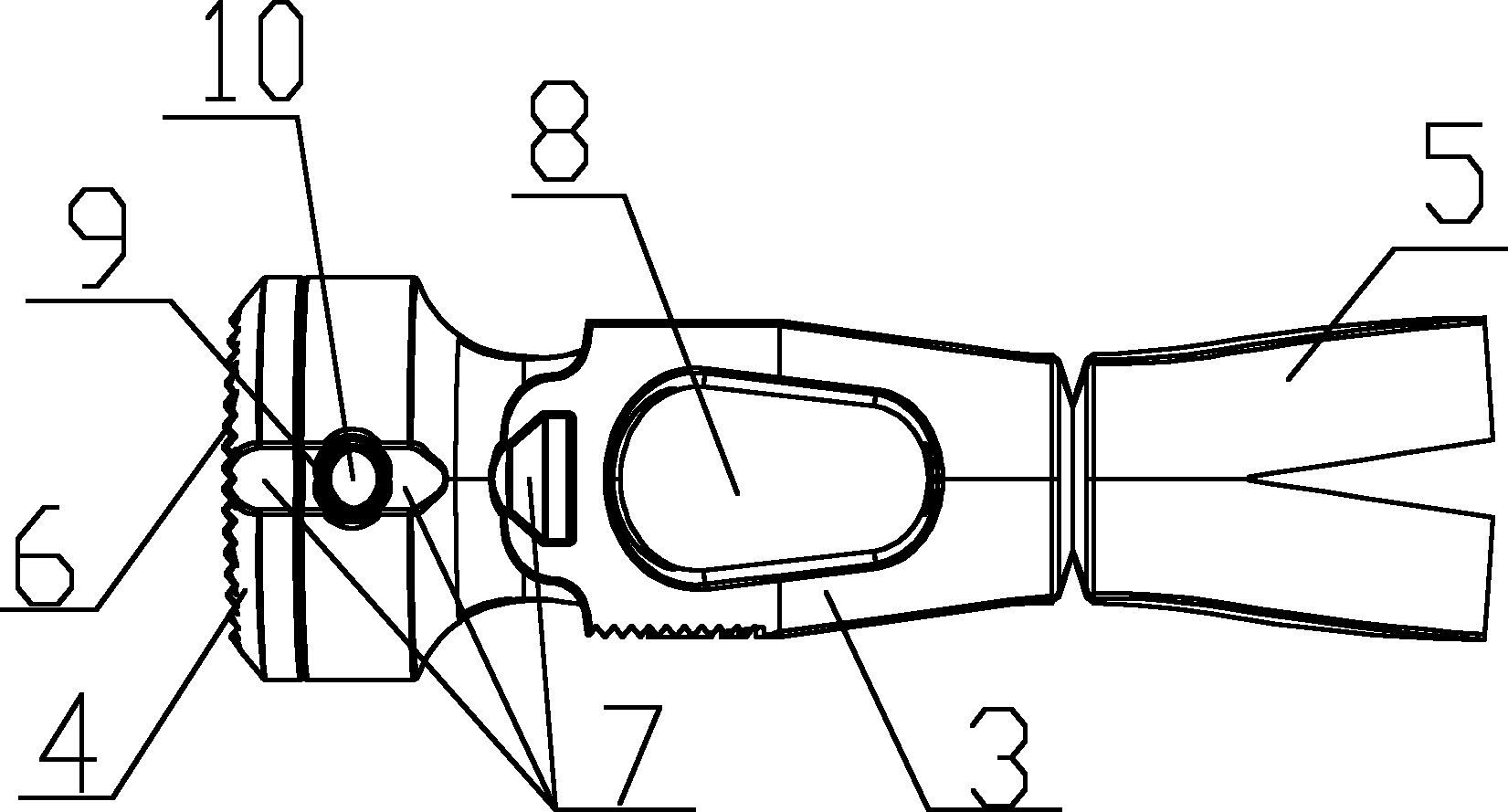

[0023] Attached below figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

[0024] The combined titanium alloy hammer has a hammer head 1 and a handle 2. The hammer head 1 is set on one end of the handle 2 through a connecting hole 8. The hammer head 1 is a split structure and consists of a body 3, a striking body 4 and a horn 5. The body 3 , The knocking body 4 and the croissant 5 adopt reliable and convenient connection methods according to different requirements: such as welding, bolt fastener connection, shrinkage connection, fixed pin connection and other methods. The knocking body 4 and horns 5 are made of forgings, the body 3 is a casting or forging and the hardness of the body 3 is lower than that of the knocking body 4 and horns 5, and the knocking body 4 and horns 5 are made of Ti-10V-3Al-2Fe , 15V-3Al-3Cr-3Sn, 4AL-22V, SP700, 13V11Cr, TC18, 2041 and other β or near β series titanium alloys, the measured tensile strength is usually between 895MPa-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com