Preparation method for stannic oxide/carbon composite hollow balls

A tin dioxide and carbon composite technology, applied in the field of material science, can solve problems such as low output and cumbersome steps, and achieve the effect of simplifying process steps, reducing costs, and realizing mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) 200 mg of tin balls with a diameter of about 100 nanometers were added to 40 ml of 0.25 mol / L glucose aqueous solution, and ultrasonicated for 10 minutes.

[0022] (2) Transfer the mixed solution obtained in step (1) to a 50 ml hydrothermal reaction kettle, raise the temperature to 180° C., keep the temperature for 180 minutes, cool down to room temperature, centrifuge and dry.

[0023] (3) The product obtained in step (2) is heat-treated in a nitrogen atmosphere at a temperature of 500° C. and kept for 180 minutes to obtain the final product, which is a tin dioxide / carbon composite hollow sphere.

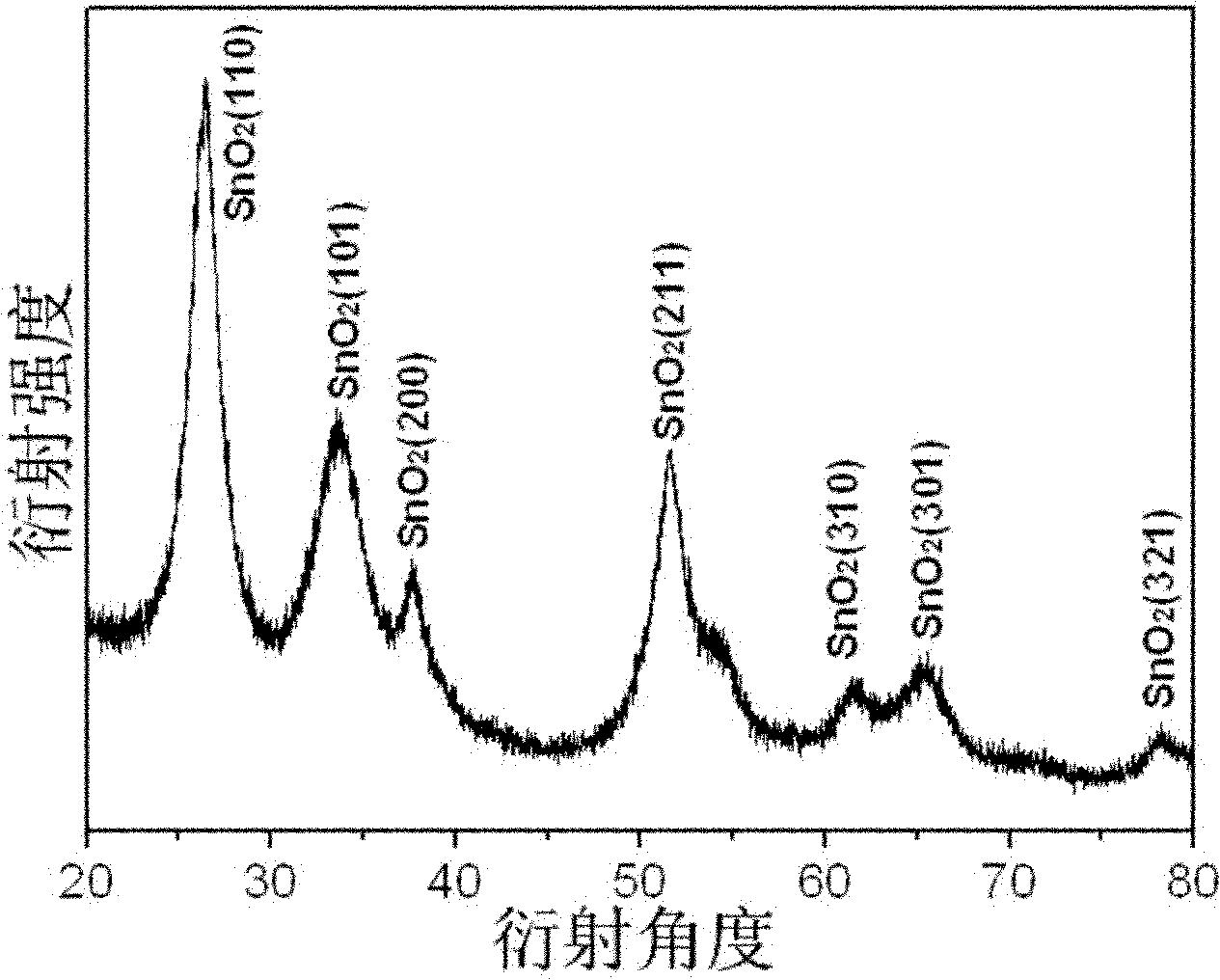

[0024] figure 1 , figure 2 and image 3 These are the scanning electron micrographs, transmission electron micrographs and X-ray diffraction patterns of the tin dioxide / carbon composite hollow spheres synthesized in this example, respectively. From Figure 1~3 It can be seen that the diameter of the obtained composite hollow sphere is 100-200 nanometers, the thickne...

Embodiment 2

[0026] (1) Add 60 mg of tin balls with a diameter of about 10 nanometers into 40 ml of 0.01 mol / L glucose aqueous solution, and sonicate for 1 minute.

[0027] (2) Transfer the mixed solution obtained in step (1) to a 50 ml hydrothermal reaction kettle, raise the temperature to 160° C., keep the temperature for 720 minutes, cool down to room temperature, centrifuge and dry.

[0028] (3) heat-treating the product obtained in step (2) in a nitrogen atmosphere at a heat treatment temperature of 400° C. for 300 minutes to obtain the final product, which is a tin dioxide / carbon composite hollow sphere. The result is similar to Example 1.

Embodiment 3

[0030] (1) 20 mg of tin balls with a diameter of about 1000 nm were added to 40 ml of 0.25 mol / L glucose aqueous solution, and ultrasonicated for 20 minutes.

[0031] (2) Transfer the mixed solution obtained in step (1) to a 50 ml hydrothermal reaction kettle, raise the temperature to 170° C., keep the temperature for 360 minutes, cool down to room temperature, centrifuge and dry.

[0032] (3) heat-treating the product obtained in step (2) in a nitrogen atmosphere at a heat treatment temperature of 450° C. and keeping it warm for 200 minutes to obtain the final product, which is a tin dioxide / carbon composite hollow sphere. The result is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com