Carbon composite material, and preparation method and application thereof

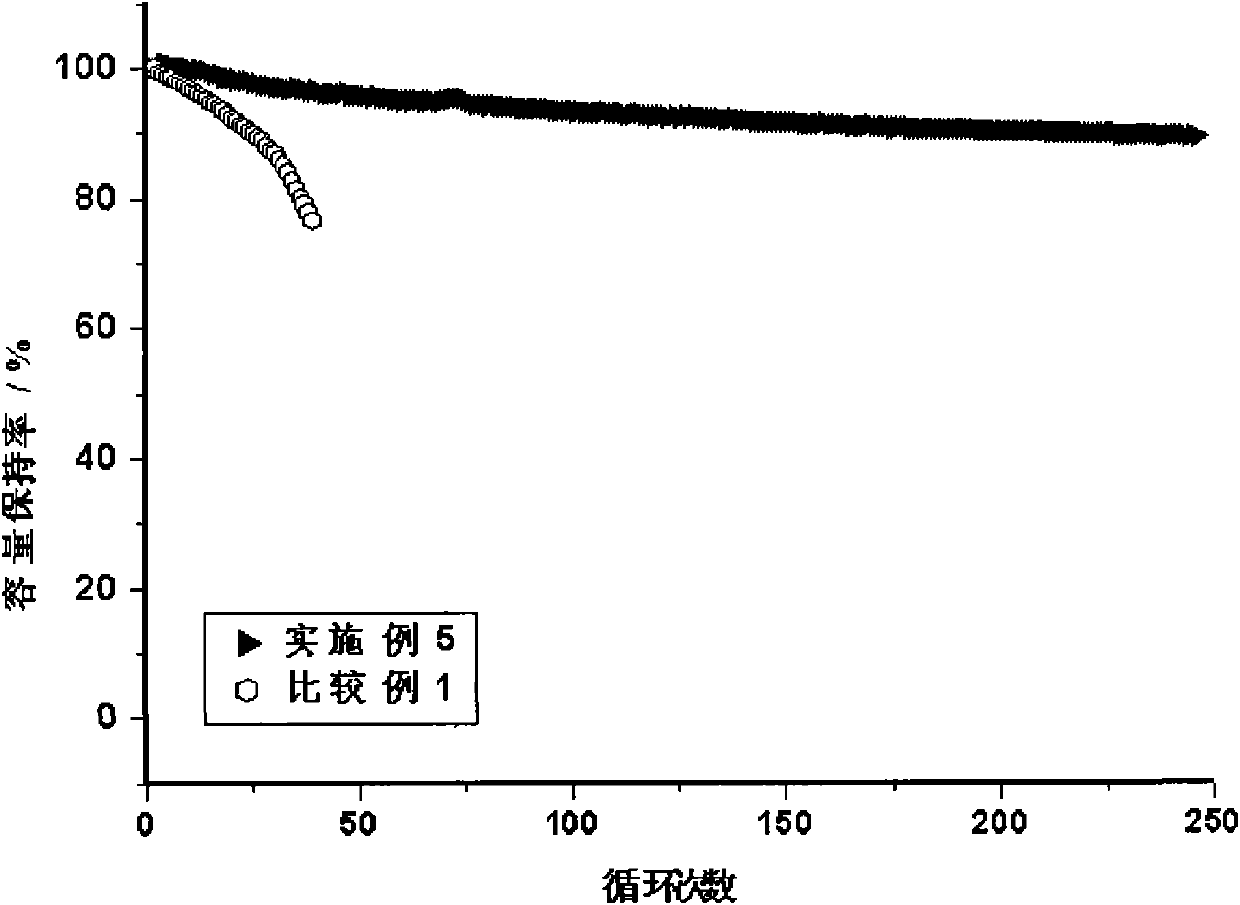

A carbon composite material and slurry technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of uneven coating of the coating layer, imperfect carbon composite material morphology, and unsatisfactory coating effect, etc. The effect of improving low temperature performance and improving high current discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention further provides a method for preparing the above-mentioned carbon composite material, the steps comprising:

[0028] a. Add graphite to the carbon-coated precursor aqueous solution, and mix the slurry;

[0029] b, the slurry obtained in step a is subjected to hydrothermal treatment, and then dried;

[0030] c. heat-treating the product obtained in step b under an inert atmosphere or vacuum condition, and the heat treatment includes carbonization treatment and graphitization treatment. The prepared material has a more perfect shape, a more uniform covering layer, easier control of the particle size of the material, and better high-current performance of the material. Further preferred steps include

[0031] a. Add graphite to the carbon-coated precursor aqueous solution, and mix the slurry;

[0032] b, the slurry obtained in step a is subjected to hydrothermal treatment, and then dried;

[0033] c, the product obtained in step b is subjected to...

Embodiment 1

[0050] (1) Carbon composite materials

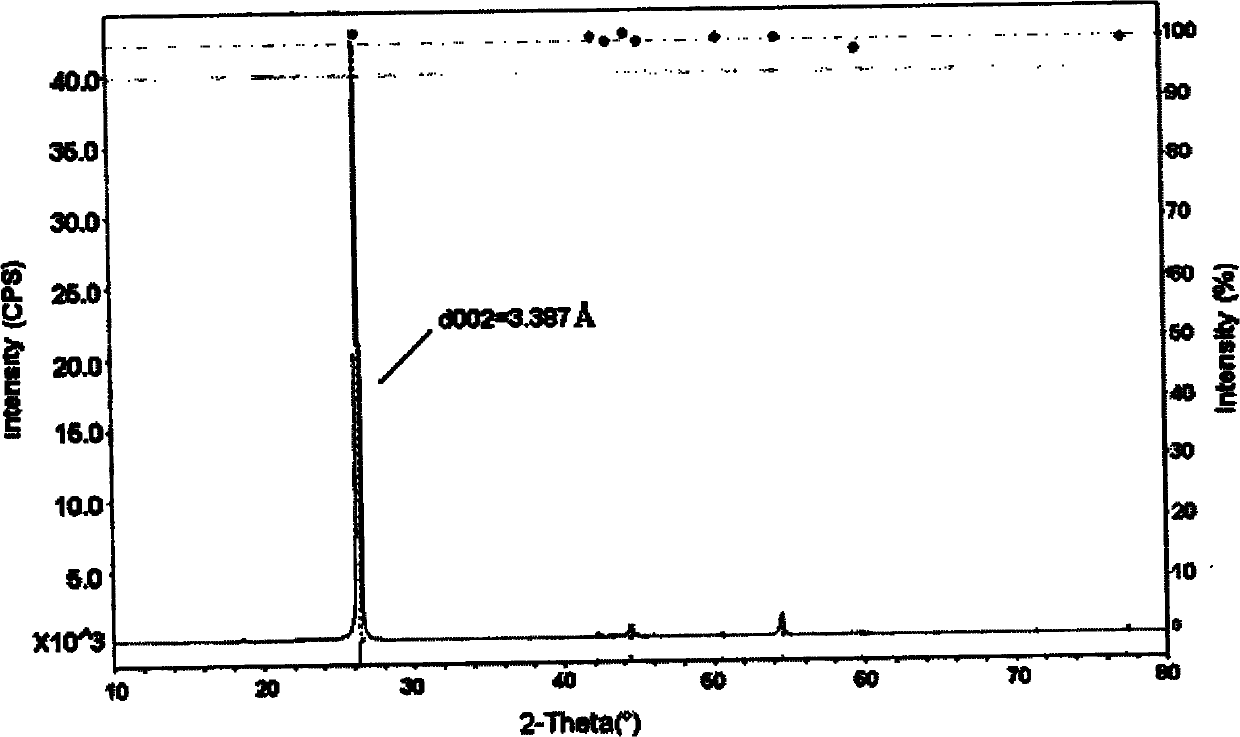

[0051] 250 g of sucrose was dissolved in water, and stirred thoroughly for 1 hour to prepare an aqueous solution of sucrose with a mass concentration of 5 wt%. The average particle size is 12.3μm, the interlayer distance (d002) is 1000g of domestic natural flake graphite (fixed carbon content 99.5%) with a particle size distribution of 3.1-35.2 μm was slowly added to a 5wt% sucrose solution, and then fully stirred for 5 hours to obtain a uniform slurry.

[0052] The slurry was transferred to an autoclave, subjected to a hydrothermal dehydration treatment at 190° C. and 500 rpm for 5 hours under a pressure of 15 mPa, washed and dried to obtain a black powder.

[0053] Put the black powder obtained above into the 2 In a protected high-temperature furnace, the temperature was raised to 1000°C at a rate of 120°C / h, and kept at a temperature of 6 hours, and then naturally cooled to room temperature to obtain a black powder.

[0054] Put t...

Embodiment 2

[0061] The carbon composite material and simulated battery were prepared by the same method as in Example 1, except that the precursor solution was 5% carboxymethyl cellulose aqueous solution.

[0062] The average particle size of the prepared carbon composite material was measured by the same method as in Example 1 to be 12.5 μm. Layer spacing (d002) is The specific surface area is 2.31m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com