Microwire wire drawing machine for aluminum-silicon bonding wire

A wire drawing machine and micro-technology, applied in the field of metal wire drawing equipment, can solve the problem that the direction of wire movement is not perpendicular to the center of the die hole, etc., and achieve high production efficiency, quality assurance, and a smooth and straight surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

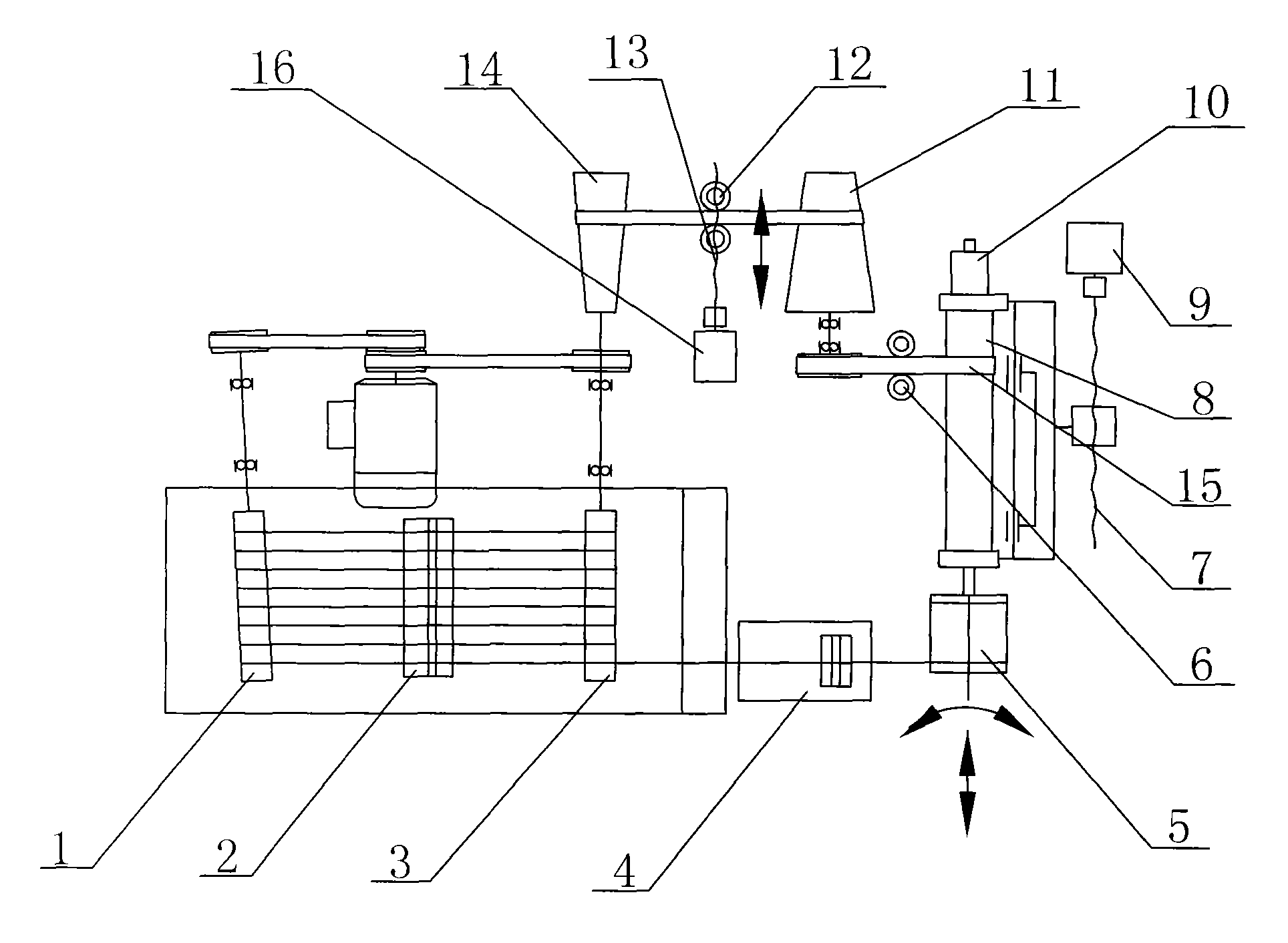

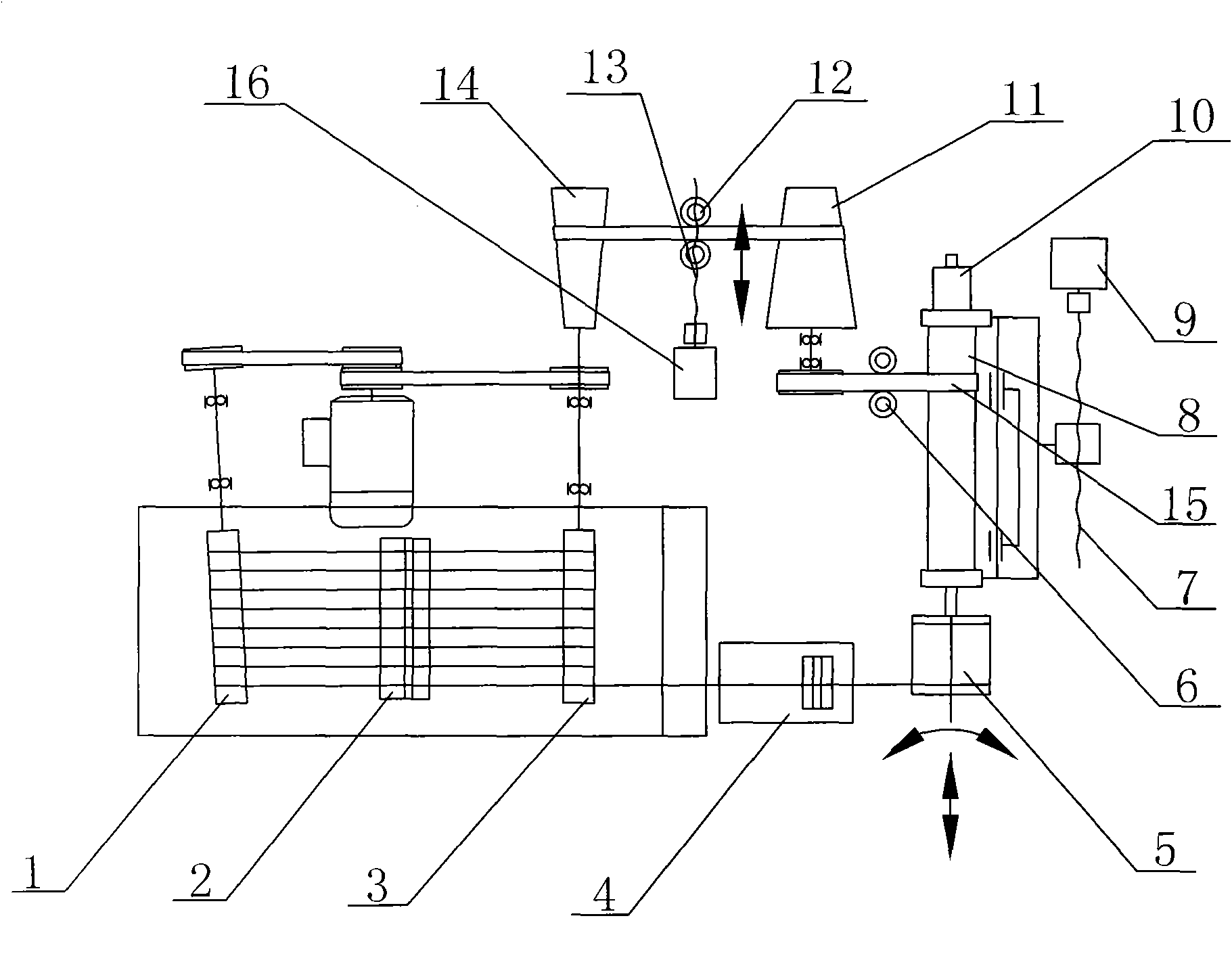

[0020] like figure 1 , a wire drawing machine for silicon-aluminum wire of the present invention includes a transmission system, a wire drawing mechanism and a wire receiving and discharging device, and the wire drawing mechanism is composed of a godet roller 1, a wire drawing die base 2, and a wire drawing roller 3 arranged in the horizontal direction in sequence. It is composed of a trimming die base 4, and the godet roller 1 and the wire drawing roller 3 form an angle of 1 to 5° inwardly in the horizontal direction. The winding wheel 5 and the encoder 10 are composed of the lower end and the upper end of the winding and discharging main shaft 8, and the winding power of the winding and discharging device is provided by a servo motor 16 arranged on one side of the winding and discharging device. The belt 15 transmits, and the power of the cable take-up and discharge device is provided by the stepping motor 9 arranged on the other side of the said take-up and discharge device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com