Ink absorption medium for color inkjet printing paper and preparation method thereof

An ink adsorption, color inkjet technology, applied in chemical instruments and methods, papermaking, paper coatings, etc., can solve the problems of inferior inkjet printing materials, and achieve the effects of fast drying speed, vivid image effect and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

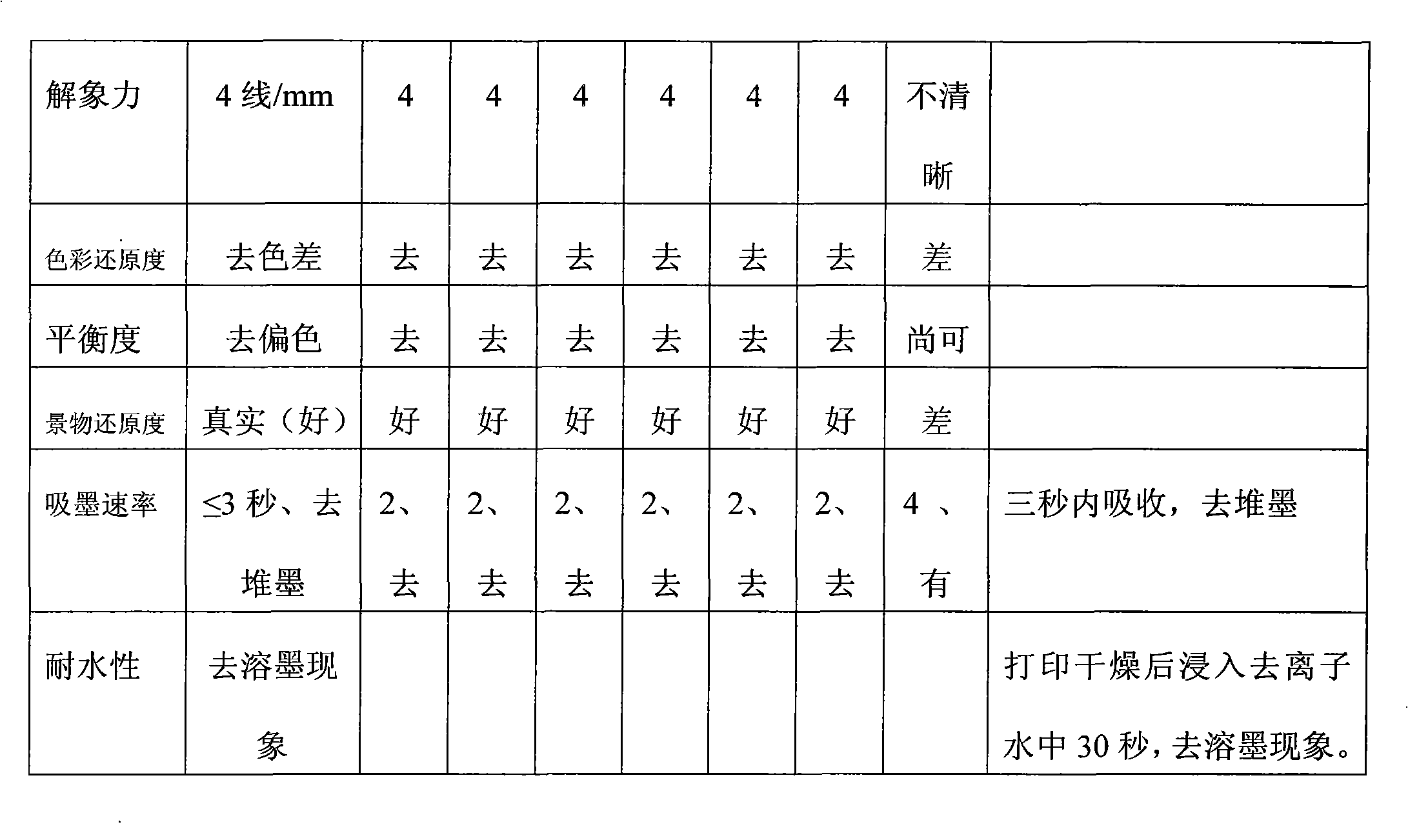

Examples

Embodiment 1

[0056] Component A: 50 parts of deionized water, 1 part of octadecyltrimethylammonium chloride, 3 parts of nonylphenol polyoxyethylene ether, 2 parts of 3-glycidyl etheroxypropyl trimethoxysilane, methylol 0.5 parts of base cellulose (weight average molecular weight is 1000), 0.2 parts of polyvinylpyrrolidone (weight average molecular weight is 2000), 20 parts of nano silicon dioxide, 0.2 parts of hydrochloric acid, 5 parts of vinyl acetate, 10 parts of methyl methacrylate , 10 parts of butyl acrylate, 0.1 part of dodecyl mercaptan, 0.5 parts of ammonium persulfate, and 2.5 parts of sodium sulfite.

[0057] Component B: 50 parts of deionized water, 3 parts of cetyltrimethylammonium chloride, 1 part of nonylphenol polyoxyethylene ether, 3 parts of 3-mercaptopropyltrimethoxysilane, hydroxymethyl cellulose 1.5 parts (weight-average molecular weight: 1000), 30 parts of nano-alumina, 0.3 parts of citric acid, 3 parts of acrylamide, 20 parts of butyl acrylate, 0.3 parts of ethyl thi...

Embodiment 2

[0067] Component A: 50 parts of deionized water, 1.5 parts of octadecyltrimethylammonium chloride, 2.5 parts of OP-2.5 parts of 3-glycidyl etheroxypropyl trimethoxysilane, 0.75 parts of hydroxymethyl cellulose (weight-average molecular weight is 2000), 0.3 parts of polyvinylpyrrolidone (weight-average molecular weight is 3000), 22 parts of nano silicon dioxide, 0.25 parts of hydrochloric acid, 6 parts of vinyl acetate, 9 parts of methyl methacrylate, 12 parts of butyl acrylate 0.15 parts of dodecyl mercaptan, 0.75 parts of ammonium persulfate, and 3.75 parts of sodium sulfite.

[0068] Component B: 50 parts of deionized water, 2.5 parts of cetyltrimethylammonium chloride, 1 part of nonylphenol polyoxyethylene ether, 2.5 parts of 3-mercaptopropyltrimethoxysilane, hydroxymethyl cellulose 1.25 parts (weight average molecular weight is 2000), 28 parts of nano-alumina, 0.35 parts of citric acid, 2.5 parts of acrylamide, 18 parts of butyl acrylate, 0.25 parts of ethyl thioglycolate,...

Embodiment 3

[0078] Component A: 50 parts of deionized water, 2 parts of octadecyltrimethylammonium chloride, 2 parts of nonylphenol polyoxyethylene ether, 3 parts of 3-glycidyl etheroxypropyl trimethoxysilane, methylol 1 part of base cellulose (weight average molecular weight is 3000), 0.4 part of polyvinylpyrrolidone (weight average molecular weight is 4000), 24 parts of nano silicon dioxide, 0.3 part of hydrochloric acid, 7 parts of vinyl acetate, 8 parts of methyl methacrylate , 16 parts of butyl acrylate, 0.2 parts of dodecyl mercaptan, 1 part of ammonium persulfate, and 5 parts of sodium sulfite.

[0079] Component B: 50 parts of deionized water, 2 parts of cetyltrimethylammonium chloride, 2 parts of nonylphenol polyoxyethylene ether, 3 parts of 3-mercaptopropyltrimethoxysilane, hydroxymethyl cellulose 1.5 parts (weight-average molecular weight: 3000), 26 parts of nano-alumina, 0.4 parts of citric acid, 2 parts of acrylamide, 16 parts of butyl acrylate, 0.2 parts of ethyl thioglycola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com