Method for preparing low temperature epoxy fatty acid branched-chain alcohol ester improver for biodiesel and application thereof

A technology of epoxy fatty acid and branched chain alcohol ester, which is applied in the production of fatty acid, esterification of fatty acid, chemical modification of fatty acid, etc., can solve the problems of low cold filter point effect of biodiesel, and achieve high industrial application value and viscosity. Reduced, high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

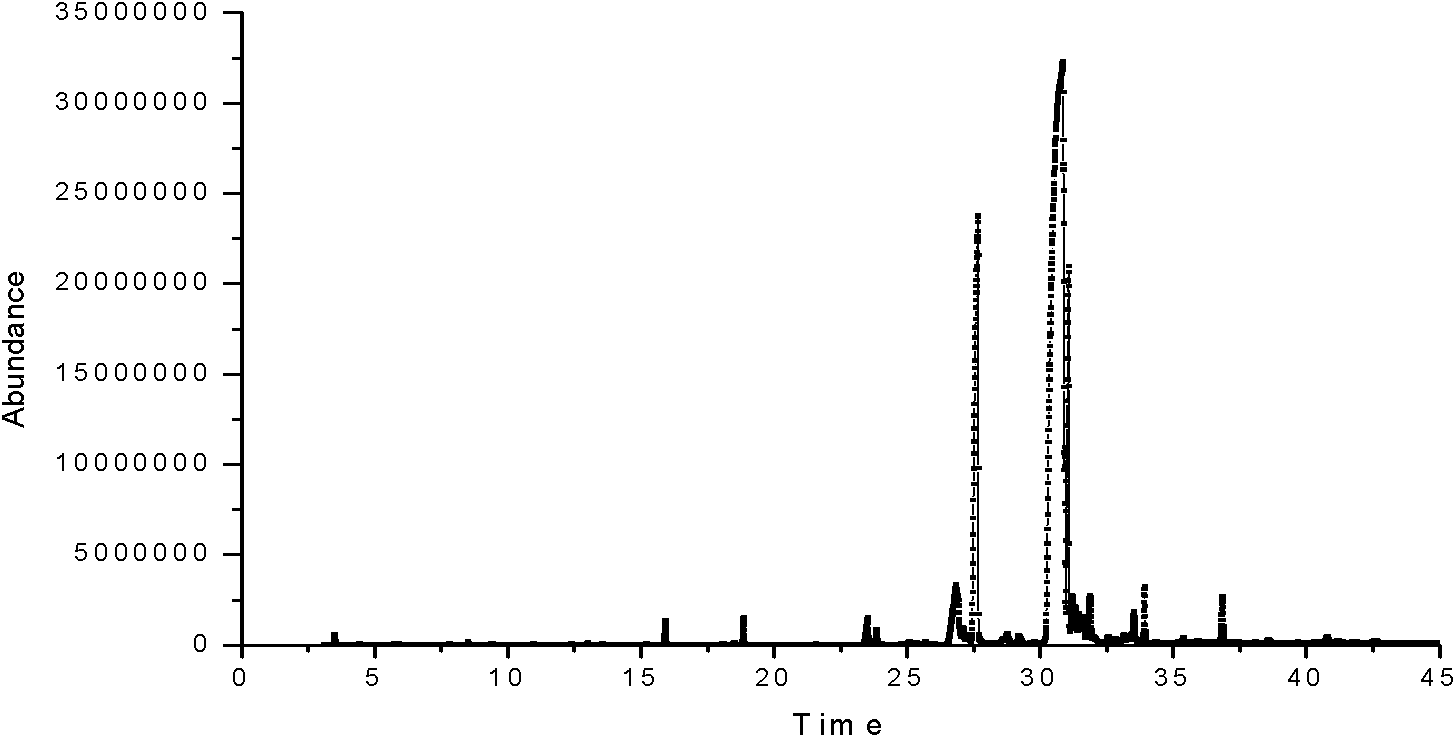

Image

Examples

preparation example Construction

[0031] After the prepared epoxy fatty acid branched chain alcohol ester low-temperature improver is mixed with biodiesel, the low-temperature flow performance is significantly improved, and the condensation point and cold filter point can be reduced by 5-15°C.

[0032] The mass of epoxy fatty acid branched chain alcohol ester accounts for 0.5-3% of biodiesel, and has high industrial application value.

[0033] The natural oils include: soybean oil, cottonseed oil, rapeseed oil, camellia oil, palm oil, catalpa oil, pistachio oil, smooth skin oil, and the content of saturated fatty acid in the raw material is ≤20%wt.

[0034] Described branched chain alcohol is: C3 branched chain alcohol: isopropanol; C4 type branched alcohol: isobutanol sec-butanol; C5 type branched alcohols: 2-methyl-1-butanol, 3-methyl-1-butanol, 2-pentanol, 3-pentanol; C6 type branched chain alcohol: 3,3-dimethyl-1-butanol, 2,3,-dimethyl-1-butanol, 2-ethyl-1-butanol, 2-methyl-1- Pentanol, 3-methyl-1-...

Embodiment 1

[0040] Step 1: Mix natural oil and branched chain alcohol, add catalyst, and react at 45-100°C for 20-120 minutes to obtain fatty acid branched-chain alcohol ester. Among them, the branched alcohol is primary alcohol or secondary alcohol, the number of carbon atoms in the alkyl group is between 3 and 8, and there is no branch on the α carbon atom of the secondary alcohol; the catalyst is an acid such as sulfuric acid, phosphoric acid, p-toluenesulfonic acid, or a catalyst It is an alkali metal hydroxide or an alkoxide of an alkali metal branched alcohol. The molar ratio of the natural oil to the branched alcohol used in the reaction is 1:1-10, and the amount of the catalyst accounts for 0.8-5% of the weight of the oil. The crude product is subjected to conventional vacuum distillation to separate the unreacted branched chain alcohol for recycling, and the remaining product is separated and separated to obtain the upper layer of fatty acid branched chain alcohol ester and the l...

Embodiment 2

[0045] Step 1: Take 100g of soybean oil with an acid value of 0.5 mgKOH / g, 92mL of isopropanol and 1g of concentrated sulfuric acid and put them into a 500mL three-necked flask. Heating to 75°C, reacting for 1.5h, distilling off unreacted alcohol under reduced pressure to obtain fatty acid isopropanol ester.

[0046] Step 2: Take 50g of fatty acid isopropanol ester and 10g of formic acid in a 250 mL three-necked flask, add 1g of concentrated sulfuric acid, stir and heat up to 45°C, then add 60g of 35% hydrogen peroxide dropwise at a rate of 20mL / h; Afterwards, the temperature was raised to 60°C, and the reaction was kept for 4 hours; the crude product was subjected to static phase separation, neutralization, and dehydration to obtain isopropanol ester of epoxy fatty acid.

[0047] Step 3, take 1g of epoxy fatty acid isopropanol ester and 100g of soybean oil biodiesel, mix well, and measure its kinematic viscosity at 40°C as 3.8mm 2 / s, the density at 20°C is 825Kg / m 3 , The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com