Catalyst component for ethylene polymerization and catalyst thereof

An ethylene polymerization and catalyst technology, applied in the field of catalyst components and catalysts, can solve the problems of complicated preparation process, increased catalyst cost, long cycle and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

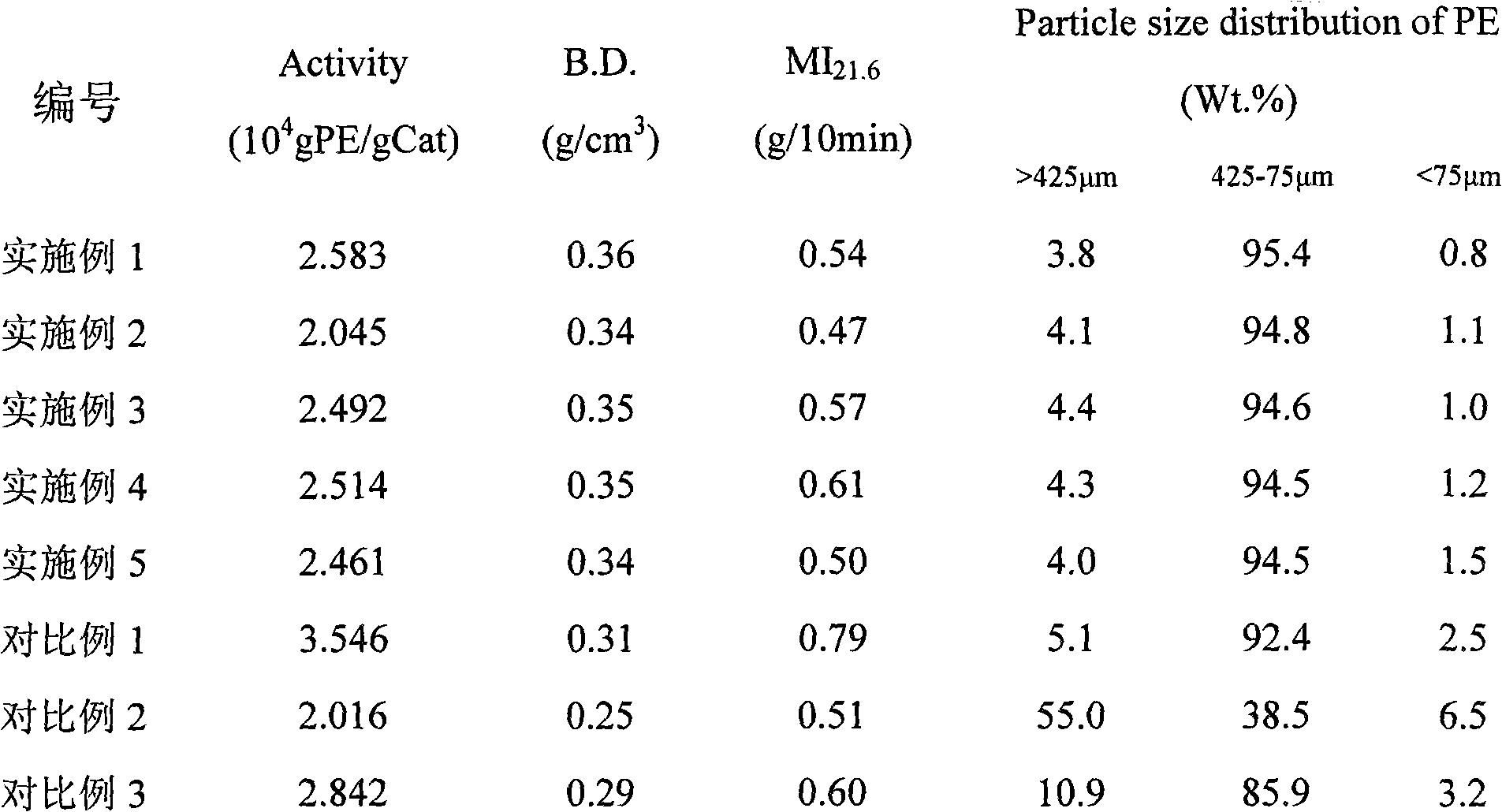

Examples

Embodiment 1

[0046] Preparation of solid titanium catalyst:

[0047] Add 2g (21mmol) of magnesium chloride and 13.7g (60mmol) of tetraethoxytitanium into 80ml of toluene, mix at room temperature for half an hour, then heat to 110°C for three hours to form a solution. 5g of silica gel (W.R.Grace & Co.-Com, 955, the pore volume is about 1.1-1.8cm 3 / g, the surface area is about 245-375m 2 / g) was added to the above solution and reacted at 40°C for 2 hours, then added 4ml of diethyl aluminum chloride solution (5mmol / ml) and reacted for 2 hours, left to settle to remove the mother liquor, washed 4 times with hexane, Then add 80ml of hexane and 10ml of titanium tetrachloride, react at 40°C for two hours, remove the upper layer of mother liquor after settling, and wash the lower layer of solid with hexane fully, and dry it to obtain catalyst powder. Ethylene polymerization:

[0048] A 2-liter autoclave was fully replaced with high-purity nitrogen, and then replaced with hydrogen. Under the co...

Embodiment 2

[0050]Add 2g (21mmol) of magnesium chloride and 13.7g (60mmol) of tetraethoxytitanium into 80ml of toluene, mix at room temperature for half an hour, then heat to 110°C for three hours to form a solution. 5g of silica gel (W.R.Grace & Co.-Com, 955, the pore volume is about 1.1-1.8cm 3 / g, the surface area is about 245-375m 2 / g) was added to the above solution, and 4ml of diethyl aluminum chloride solution (5mmol / ml) was added simultaneously, and after reacting for 4 hours at a temperature of 40°C, the mother liquor was left to settle to remove, washed 4 times with hexane, and then Add 80ml of hexane and 10ml of titanium tetrachloride, react at 40°C for two hours, remove the upper layer of mother liquor after settling, and wash the lower layer of solid with hexane to obtain catalyst powder after drying. The catalyst was polymerized in the same manner as in Example 1, and the results are listed in Table 1.

Embodiment 3

[0052] Add 2g (21mmol) of magnesium chloride and 13.7g (60mmol) of tetraethoxytitanium into 80ml of toluene, mix at room temperature for half an hour, then heat to 110°C for three hours to form a solution. With 5g of silica gel (PQ Corporation, MS3050, the pore volume is about 2.4-3.7cm 3 / g, the surface area is about 410-620m 2 / g) was added to the above solution and reacted at 80°C for 2 hours, then added 4ml of diethyl aluminum chloride solution (5mmol / ml) and reacted for 2 hours, left to settle to remove the mother liquor, washed 4 times with hexane, Then add 80ml of hexane and 10ml of titanium tetrachloride, react at 40°C for two hours, remove the upper layer of mother liquor after settling, and wash the lower layer of solid with hexane fully, and dry it to obtain catalyst powder. The catalyst was polymerized in the same manner as in Example 1, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com