Surface metallization joint method of ceramic and aluminum or aluminum alloy

A technology of aluminum alloy and ceramics, which is applied in the field of surface metallization connection of ceramics and aluminum or aluminum alloys. It can solve the problems of poor performance of the connector and hinder the connection of aluminum and ceramics, so as to ensure accuracy, prevent unconnected defects, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

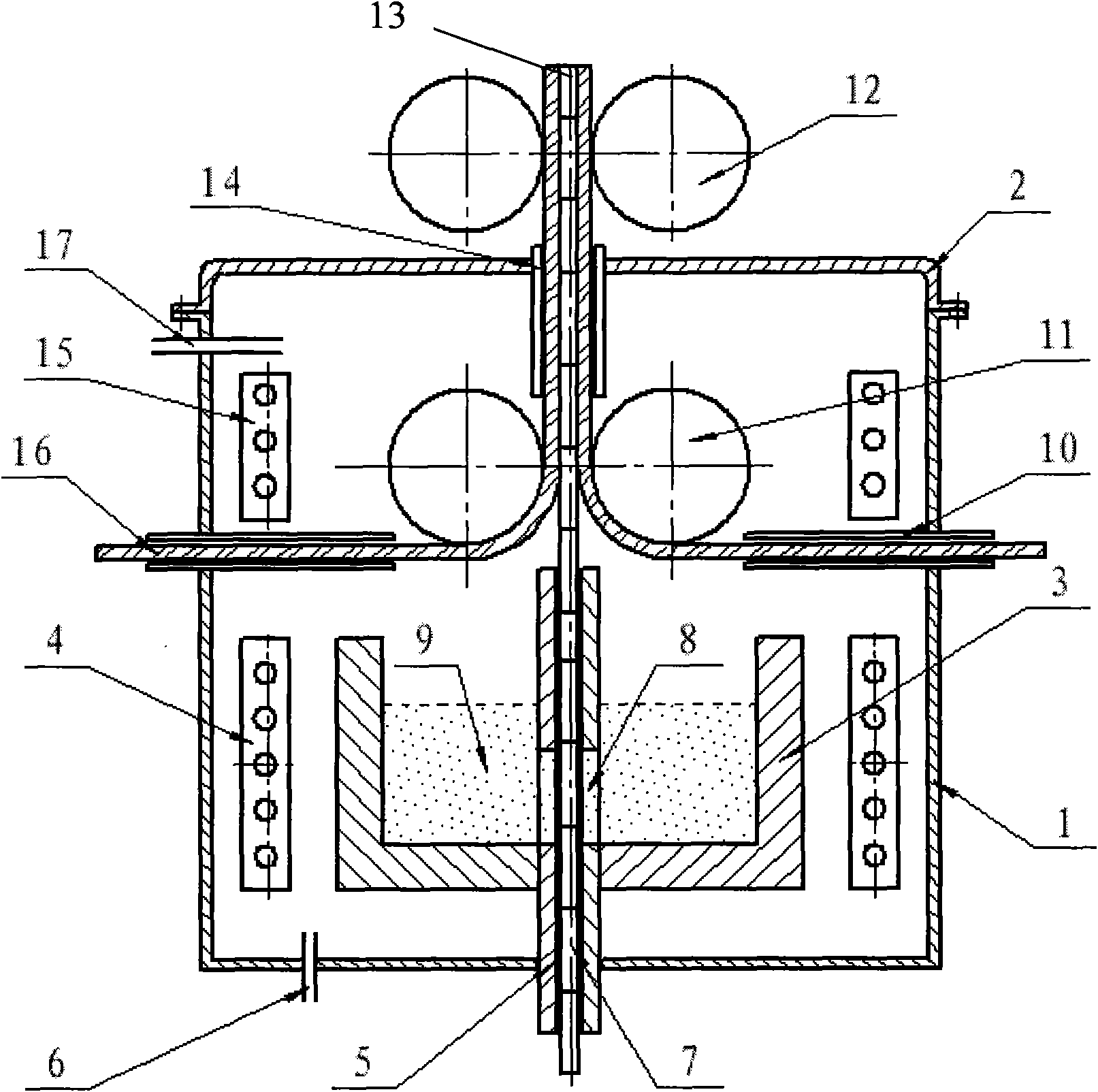

[0028] Embodiment 1, adopt the above-mentioned ceramic surface metallization connection device, put the Al-12wt% Si alloy into the graphite crucible, put the alumina ceramic plate (length 137mm, width 35mm, thickness 0.64mm, Tsinghua Yueke production, the alumina purity is greater than 95%) was inserted into the graphite guide rail passing through the crucible, the aluminum strip with a thickness of 0.5mm was introduced from the inlet, passed through the guide wheel and the driving wheel and led out from the outlet, and then in a nitrogen atmosphere (both the upper and lower nitrogen inlet flow rates were 20 liters) / min) heating to melt the aluminum alloy and raise the temperature to 730°C. Insert another alumina ceramic plate into the guide rail at a speed of 68.5mm / min from the guide rail entrance at the lower part of the device, and push the ceramic plate inserted into the guide rail to move vertically upward at the same speed. During the moving process, the ceramic plate ...

Embodiment 2

[0031] Example 2, except that the temperature of the upper heating body was set to 620° C., the rest was the same as that of Example 1. Observation of metallographic samples shows that the aluminum plate is closely connected on the ceramic plate, and no unconnected place is found at the interface. The tear strength was 12.0 N / mm, and fracture occurred in the aluminum nip. The experiment was repeated three times. The strength of the aluminum and ceramic connection interface is greater than 10.8N / mm.

Embodiment 3

[0032] Example 3: The rest is the same as Example 1, except that the alloy is changed to Al-12wt%Si-0.5wt%Mg alloy, and the upper and lower nitrogen flow rates are reduced to 10 liters / min. There is no defect in the connection interface between the ceramic and the aluminum, and the fracture occurs in the clamping part of the aluminum in the tear strength test. The experiment was repeated three times, and the interface connection strength was greater than 9.7N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com