Method for preparing superfine zirconia powder

A technology of ultra-fine zirconia and zirconia powder, which is applied in the field of ceramic materials, can solve the problems of restricting production enterprises, and achieve the effect of uniform particle size and short aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

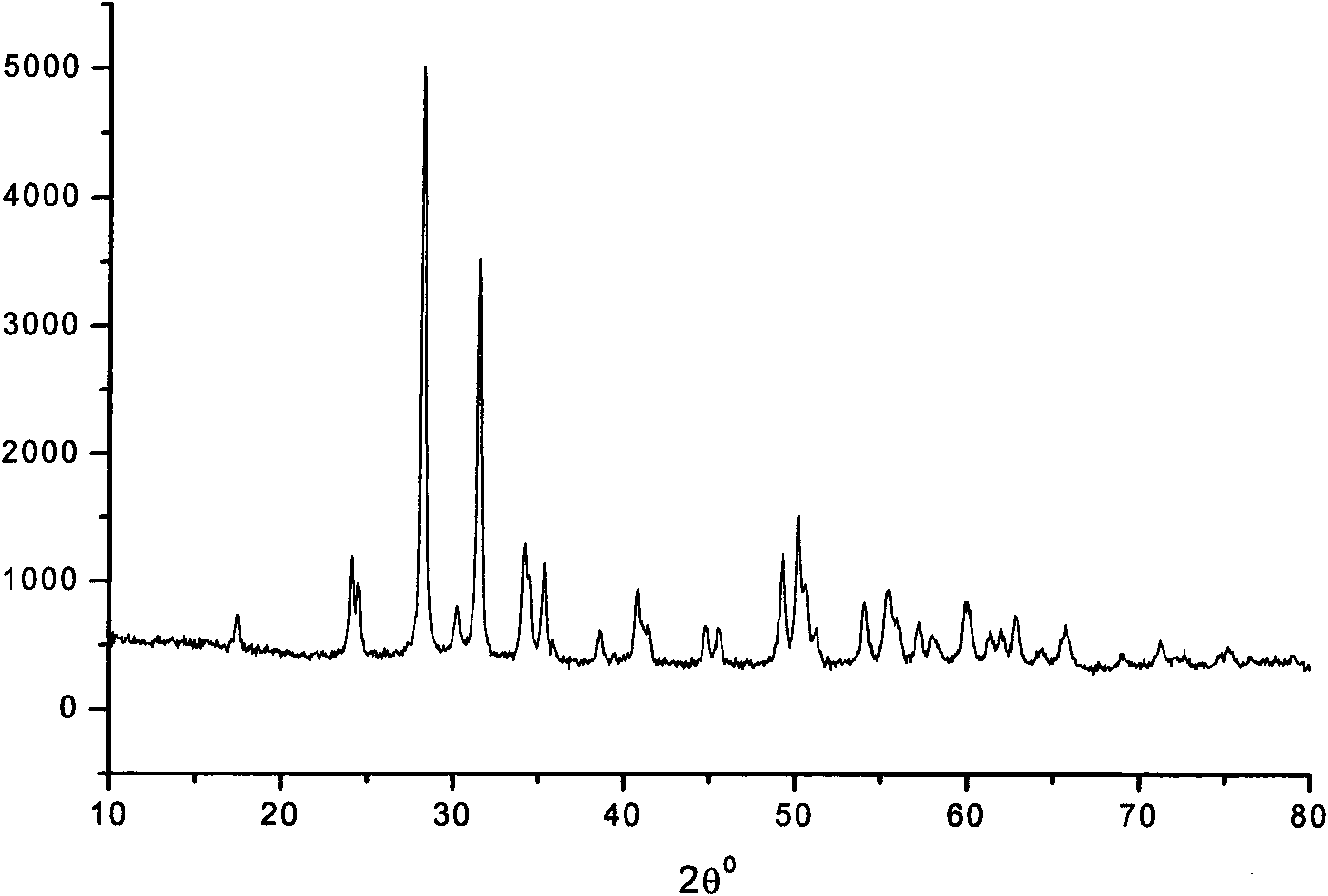

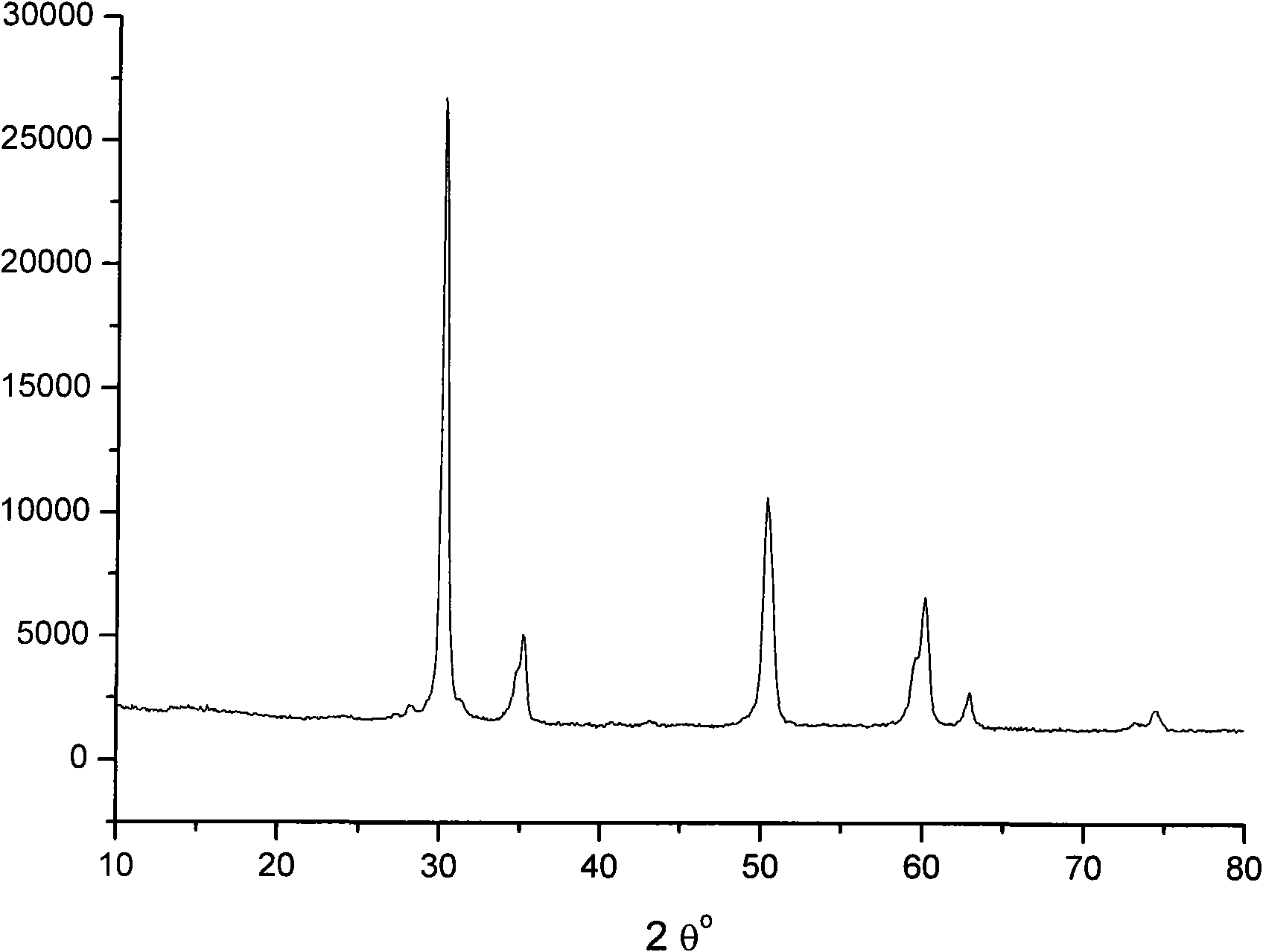

Image

Examples

Embodiment 1

[0024] The preparation method of ultrafine zirconia powder comprises the following steps:

[0025] (1) 16.27gZrOCl 2 ·8H 2 O was dissolved in 50ml of deionized water to make a 1mol / L zirconium oxychloride solution, and 100.32g of tetraethylammonium hydroxide (C8H20NOH 25%) was weighed; the two solutions were quickly stirred and mixed at a speed greater than 400 rpm Reaction, the temperature is controlled at 40°C, the pH is controlled between 11-12 by precision pH test paper, and the reaction is carried out for 10 minutes to prepare the zirconium hydroxide precursor;

[0026] (2) The precursor is filtered and washed with deionized water until the filtrate is detected to be free of Cl with silver nitrate solution - , to prepare zirconium hydroxide filter cake;

[0027] (3) Stir and disperse the obtained zirconium hydroxide filter cake in n-butanol, then heat it to 80°C under the condition of vacuum degree of 0.1 MPa, and recover the water-containing alcohol by vacuum azeotrop...

Embodiment 2

[0030] The steps of the preparation method of ultrafine zirconia powder are as described in Example 1, and the precipitating agent is adjusted to adopt 70.83g of tetramethylammonium hydroxide (25%); 16.21gZrOCl 2 ·8H 2 O was dissolved in 50ml of deionized water to make a 1mol / L zirconium oxychloride solution. The reaction temperature was controlled at 50°C; the pH was kept between 12-13, and the reaction was carried out for 15 minutes; the drying temperature was 80°C, and azeotropic distillation was carried out for 8 hours; the calcination temperature was controlled at Calcined at 600°C for 3h. Prepare ultrafine zirconia powder.

Embodiment 3

[0032] The steps of the preparation method of ultrafine zirconia powder are as described in Example 1, the concentration of zirconium oxychloride is adjusted, and 16.12gZrOCl 2 ·8H 2 O was dissolved in 62.5ml deionized water to make a 0.8mol / L zirconium oxychloride solution; the precipitation agent was tetramethylammonium hydroxide (25%), and 70.12g was weighed; the temperature was controlled at 50°C, and the pH was maintained at 12- Between 13 and 5 minutes of reaction; the alcohol used in the azeotropic distillation is n-pentanol, the drying temperature is 80°C, and the azeotropic distillation is carried out for 8 hours; calcined at 700°C for 2 hours; ultrafine zirconia powder is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com