Method for preparing anticoagulant polysulfones material by fourier reaction grafting

A technology of Fourier reaction and anticoagulation, which is applied in anticoagulation treatment, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. It can solve the problem of coagulation and thrombus affecting the application and effect of polysulfone devices, etc. problems, achieve good anticoagulant performance, improve blood compatibility, and reduce platelet adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

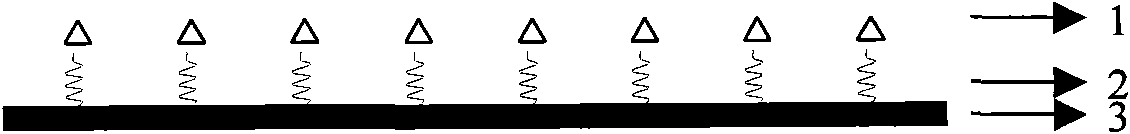

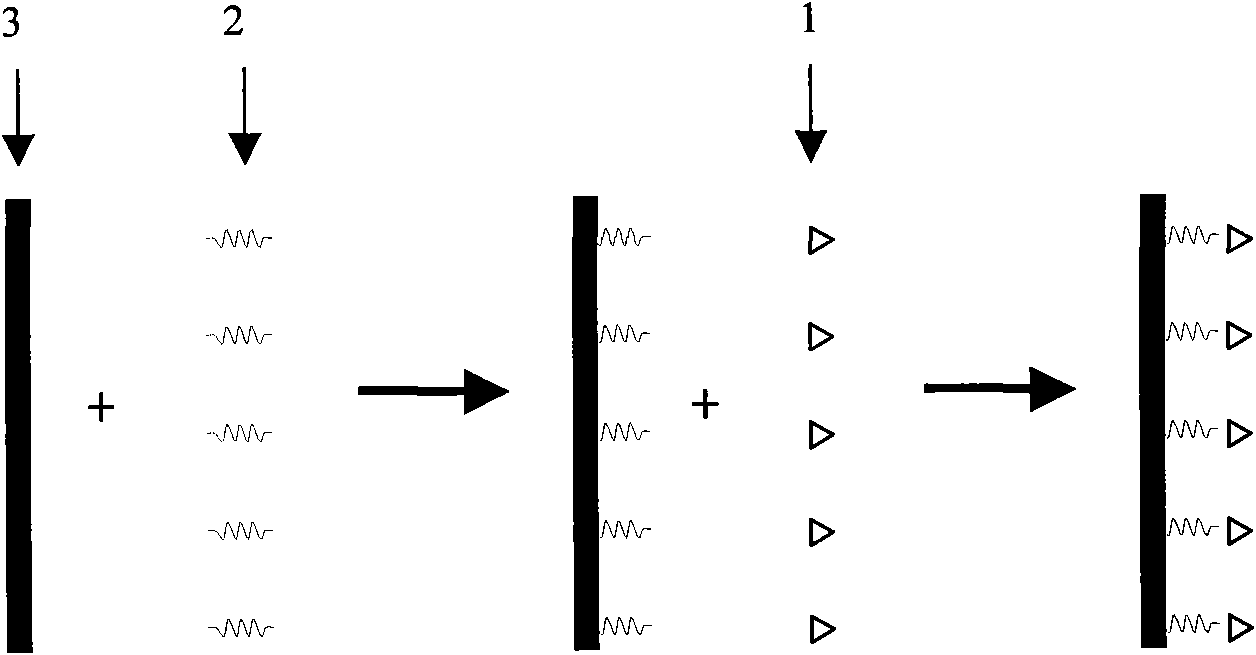

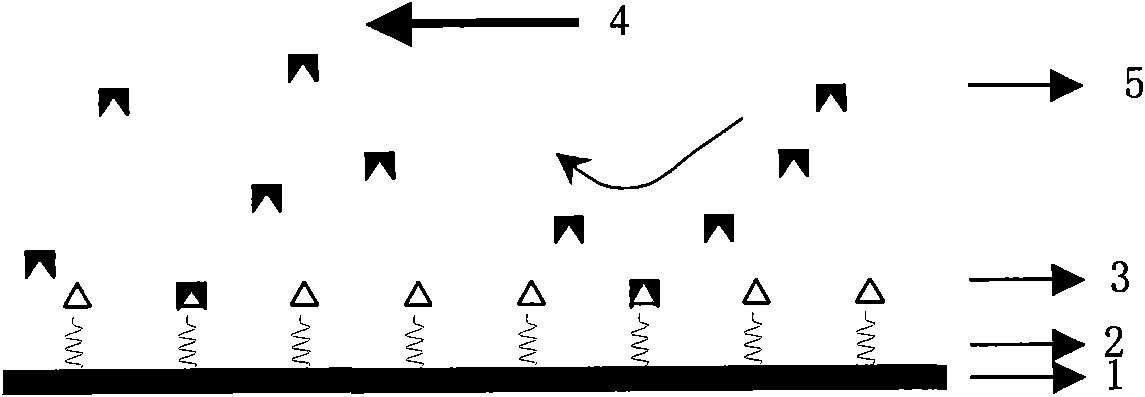

[0046] (1) Preparation of carboxylated polysulfone surface: Dissolve tin tetrachloride with a molar ratio of 0.05:1 to acrylic acid in a mixed solution of acrylic acid:phosphoric acid (V:V is 3:1), and immerse the polysulfone membrane in 50 mL of the solution Medium, 30°C for 60 minutes, rinse thoroughly with triple distilled water. Energy spectrum analysis shows that the surface of the obtained polysulfone is carboxylated, so the content of oxygen element increases.

[0047] (2) Preparation of aminated polysulfone surface: prepare 90% ethanol aqueous solution, then take 1 part of KH550 and dissolve it in 49 parts of ethanol aqueous solution, immerse the above-mentioned polysulfone membrane in 50 mL of the solution, and after grafting at room temperature for 30 minutes, 90 % ethanol, triple distilled water to fully rinse. Energy spectrum analysis shows that the silicon element in silane appears on the surface of the polysulfone obtained (see Figure 4b ).

[0048] (3) Prepa...

Embodiment 2

[0057] (1) Preparation of carboxylated polysulfone surface: Dissolve tin tetrachloride with a molar ratio of 0.05:1 to acrylic acid in a mixed solution of acrylic acid: phosphoric acid (V: V is 1: 1), and immerse the polysulfone membrane in 50 mL of the solution Medium, 40°C for 30 minutes, rinse thoroughly with triple distilled water. Energy spectrum analysis shows that the surface of the obtained polysulfone is carboxylated, so the content of oxygen element increases.

[0058] (2) Preparation of aminated polysulfone surface: Same as in Example 1. Energy spectrum analysis shows that the silicon element in silane appears on the surface of the obtained polysulfone.

[0059] (3) Preparation of a polysulfone surface on which an anticoagulant is grafted: same as in Example 1. Energy spectrum analysis showed that the kurtosis of silicon element on the surface of polysulfone decreased obviously.

[0060] (4) Evaluation of anticoagulant performance: same as in Example 1.

[0061]...

Embodiment 3

[0063] (1) Preparation of carboxylated polysulfone surface: Same as Example 1. Energy spectrum analysis shows that the surface of the obtained polysulfone is carboxylated, so the content of oxygen element increases.

[0064] (2) Preparation of aminated polysulfone surface: prepare 0.2% KH550 silane solution with 90% ethanol, immerse the polysulfone membrane in 50 mL of the solution, graft overnight at room temperature, and rinse thoroughly with 90% ethanol and triple distilled water. Energy spectrum analysis shows that the silicon element in silane appears on the surface of the obtained polysulfone.

[0065] (3) Preparation of polysulfone material grafted with anticoagulant: same as in Example 1. Energy spectrum analysis showed that the kurtosis of silicon element on the surface of polysulfone decreased obviously.

[0066] (4) Evaluation of anticoagulant performance: same as in Example 1.

[0067] The results of recalcification time test, hemolysis rate test, platelet adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com