Silicone oil microcapsule with slow-release characteristics and preparation method thereof

A technology of microcapsule and silicone oil, applied in the direction of coating, can solve the problems of poor heat resistance of silicone oil microcapsule wall, complicated preparation process, poor environmental protection, etc., and achieve the effects of low cost, simple process and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

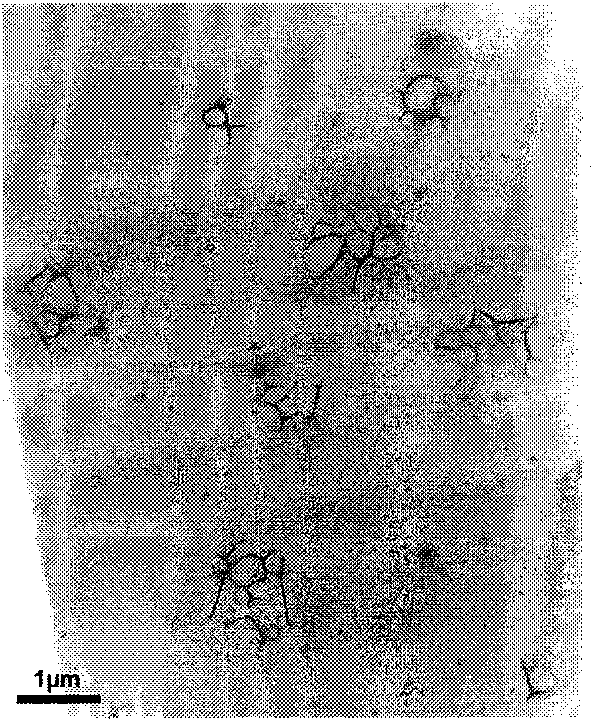

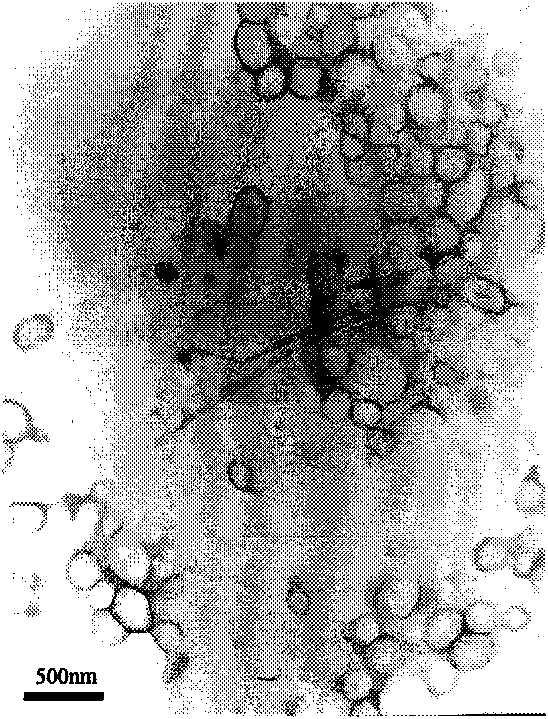

[0023] Dissolve 0.25 g of sodium dodecylsulfonate and 0.75 g of high-carbon fatty alcohol polyoxyethylene ether in 100 g of deionized water, and then add 10 g of simethicone, 10 g of TEOS, and 1 g of octadecyl trimethyl The oil phase mixture composed of oxysilane was pre-emulsified and stirred for 15 minutes in an ice-water bath environment, and then ultrasonically fine-emulsified for 20 minutes using a cell pulverizer to obtain a fine emulsion. Adjust the pH value of the miniemulsion to 7.5, and stir at a high speed at room temperature for 24 hours to obtain a milky white silicone oil microcapsule suspension.

[0024] 3.91 g of the above silicone oil microcapsule suspension, 10 g of water, 3.76 g of silicone acrylic emulsion (solid content 46%), 3 g of titanium dioxide, and 0.06 g of BYK-1540.06 g were prepared into a coating, coated, and dried at room temperature for 12 hours to obtain a hydrophobic coating.

Embodiment 2

[0026] Dissolve 0.25 g of sodium dodecylsulfonate and 0.75 g of alkylphenol polyoxyethylene ether in 100 g of deionized water, then add 10 g of simethicone, 7 g of TEOS, and 1.5 g of cetyl trimethoxy Oil phase mixture composed of base silane. Pre-emulsified and stirred for 15 minutes in an ice-water bath environment, and then ultrasonically fine-emulsified for 20 minutes using a cell pulverizer to obtain a fine emulsion. Adjust the pH value of the miniemulsion to 8, and stir at a high speed at room temperature for 24 hours to obtain a milky white silicone oil microcapsule suspension.

[0027] 3.25 grams of the above silicone oil microcapsule suspension, 10 grams of water, 3.11 grams of silicone acrylic emulsion (solid content 46%), 3 grams of titanium dioxide, and 0.06 grams of BYK-1540.06 were formulated into a coating, coated, and dried at room temperature for 12 hours to obtain a hydrophobic coating.

Embodiment 3

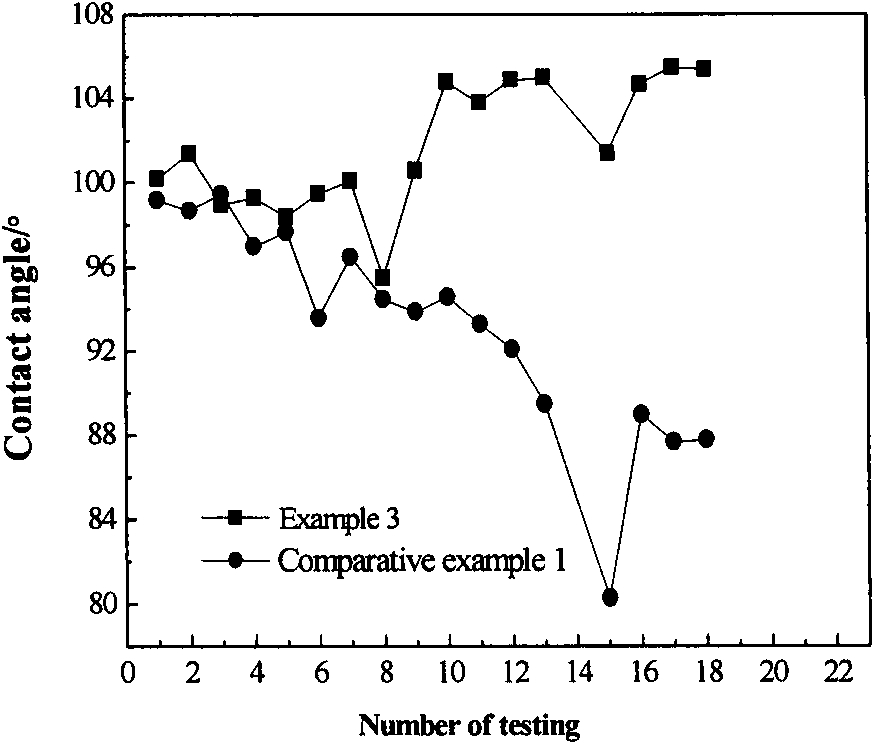

[0029] Dissolve 0.25 g of sodium dodecylsulfonate and 0.75 g of alkylphenol polyoxyethylene ether in 100 g of deionized water, then add 10 g of simethicone, 10 g of TEOS, and 1.5 g of octadecyl trimethoxy The oil phase mixture composed of base silane was pre-emulsified and stirred for 15 minutes in an ice-water bath environment, and then ultrasonically fine-emulsified for 20 minutes using a cell pulverizer to obtain a fine emulsion. Adjust the pH value of the miniemulsion to 7.5, and stir at a high speed at room temperature for 24 hours to obtain a milky white silicone oil microcapsule suspension.

[0030] 3.41 grams of the above silicone oil microcapsule suspension, 10 grams of water, 3.26 grams of silicone acrylic emulsion (solid content 46%), 3 grams of titanium dioxide, and 0.06 grams of BYK-1540.06 were formulated into a coating, coated, and dried at room temperature for 12 hours to obtain a hydrophobic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com