Method for preparing nano silicon/polyacrylate composite emulsion

A technology of nano-silica and polyacrylate, which is applied in the direction of coating, etc., can solve the problems of complex process and easy agglomeration of nano-silica, and achieve the effects of simplifying the process, good dispersion, and avoiding secondary agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

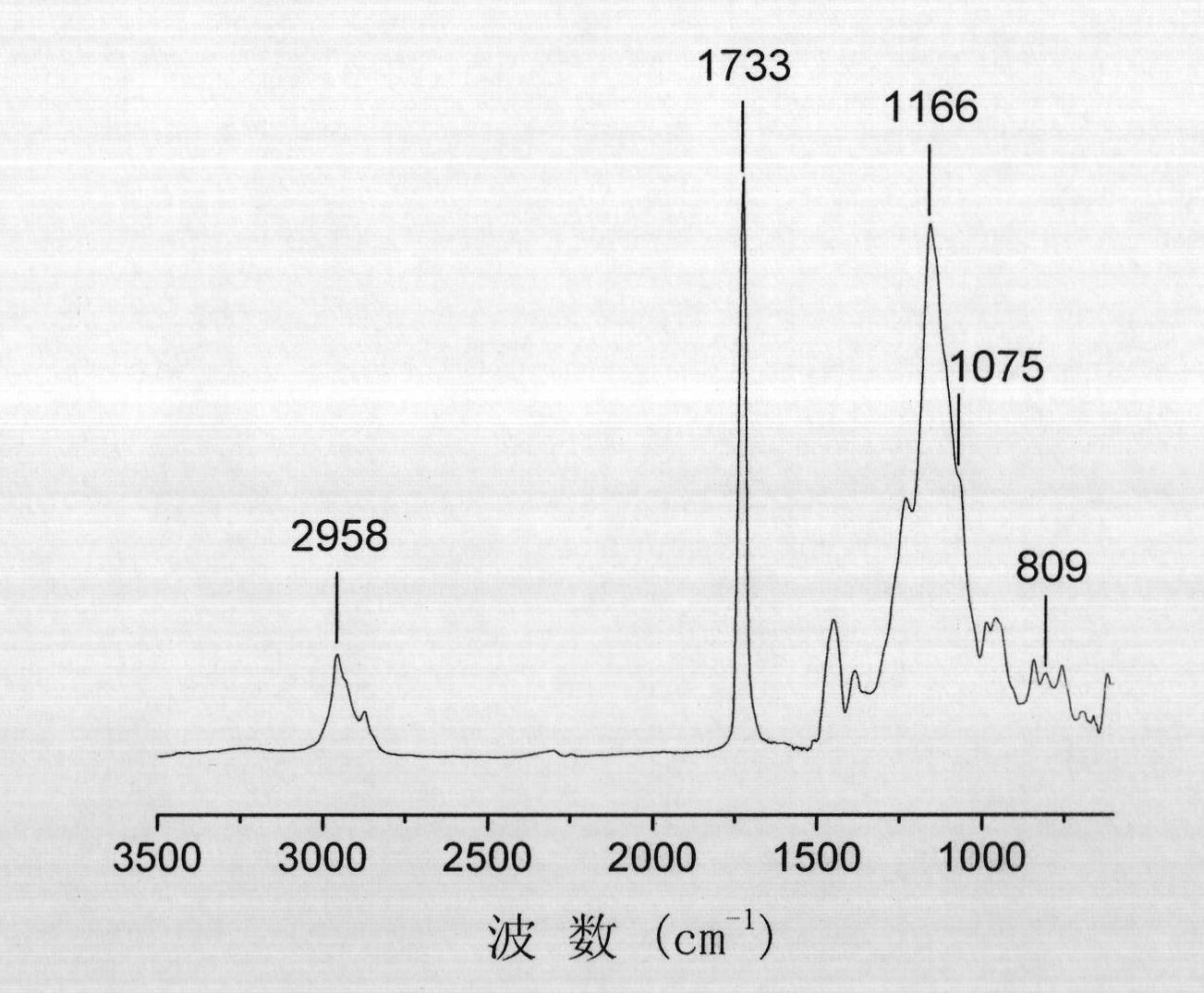

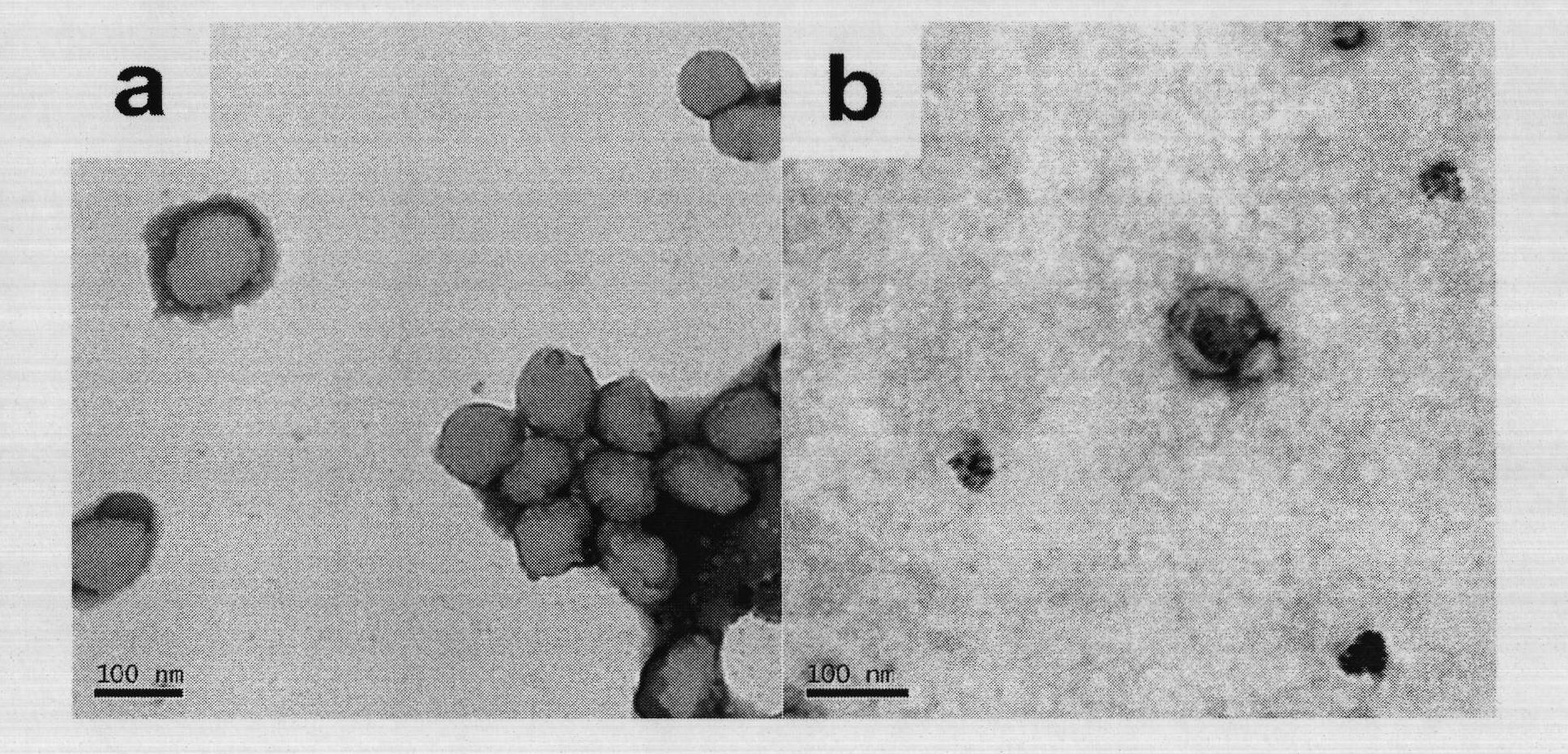

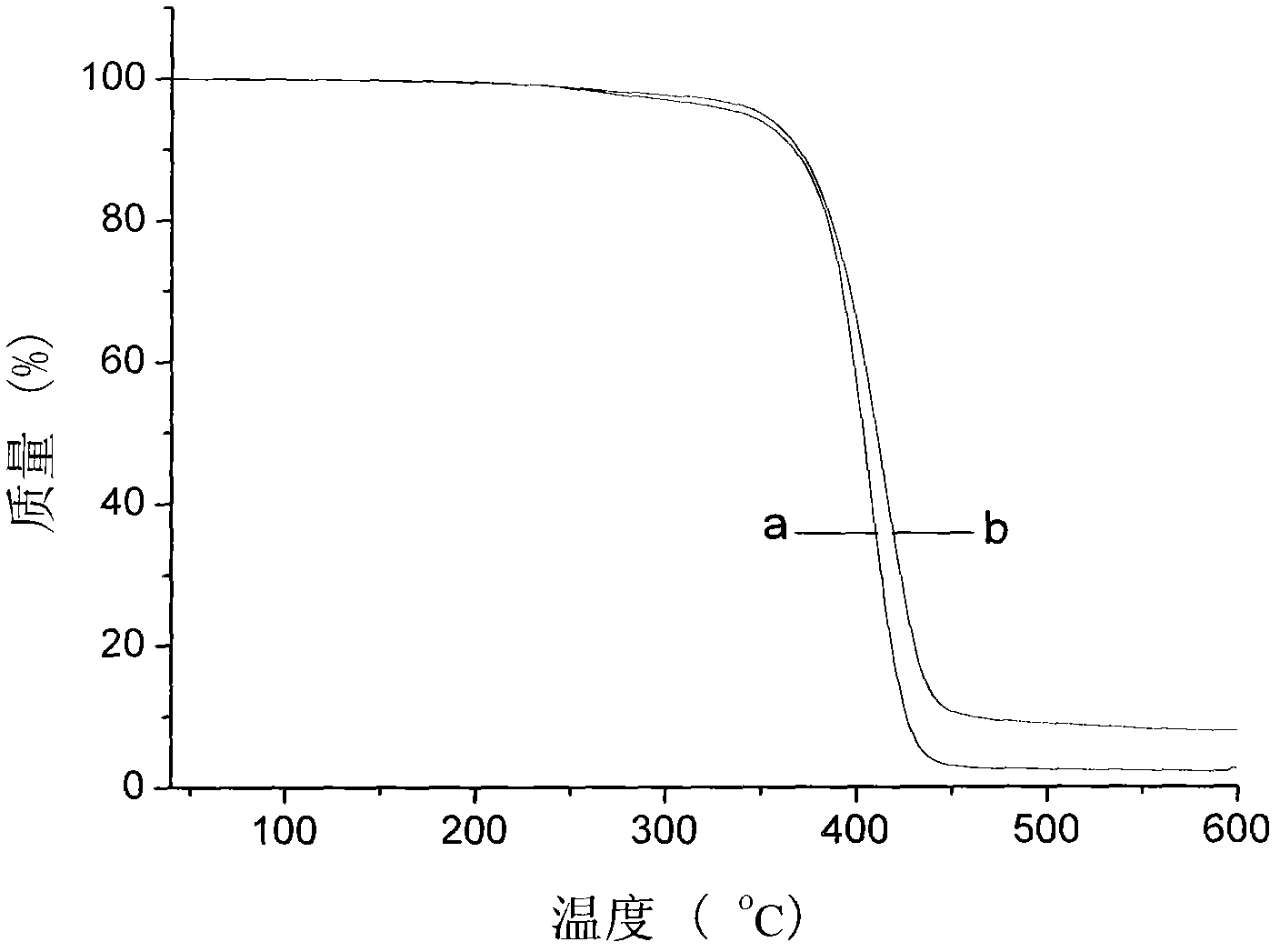

[0028] Add 2.0g of allyloxynonylphenol propanol polyoxyethylene ether ammonium sulfate (DNS-86) and 0.013g of concentrated hydrochloric acid (mass concentration 36%) into 25g of deionized water, and mix with 10g of butyl acrylate and 10g of methyl methacrylate. The mixed liquid of methyl acrylate, 5.5 g of ethyl orthosilicate and 0.5 g of KH-570 was pre-emulsified for 10 minutes and stirred on a magnetic stirrer for 12 hours to prepare a modified nano-silica pre-emulsion.

[0029] At a temperature of 75° C., the modified nano-silica emulsion was added dropwise to 35 g of deionized water within 1.5 hours, and 10 g of potassium persulfate aqueous solution with a weight concentration of 1.5% was added, and the temperature was maintained for 30 minutes.

[0030] At the same time, 0.4g DNS-86, 10g butyl acrylate, 10g methyl methacrylate, 1.6g acrylic acid and 20g deionized water were pre-emulsified for 5 minutes to prepare acrylate pre-emulsion, and then the acrylate was added dropwise w...

Embodiment 2

[0035] Add 1.3g DNS-86 and 0.01g concentrated hydrochloric acid (mass concentration 36%) into 25g deionized water, and add 5g 2-ethylhexyl methacrylate, 5g methyl acrylate, 1.5g ethyl orthosilicate Pre-emulsify the mixture with 0.1g KH-570 for 10 minutes and stir for 8 hours on a magnetic stirrer to prepare a modified nano-silica pre-emulsion. At 75° C., the modified nano-silica emulsion was added dropwise to 35 g of deionized water within 1 h, and 5 g of potassium persulfate aqueous solution with a weight concentration of 1% was added, and the temperature was kept for 20 minutes. At the same time, 0.2g DNS-86, 10g butyl acrylate, 10g methyl methacrylate, 0.6g acrylic acid and 20g deionized water were pre-emulsified for 5 minutes to prepare acrylate pre-emulsion, and then the acrylate was added dropwise within 2h Pre-emulsion and 5g of potassium persulfate aqueous solution with a mass concentration of 1%. After the addition, the temperature was raised to 80°C, and the temperat...

Embodiment 3

[0037] 1.5g DNS-86, 0.8g allyloxy nonyl phenol propanol polyoxyethylene (ANPEO 10 ) And 0.03g concentrated hydrochloric acid (mass concentration 36%) were added to 30g deionized water, and pre-emulsified with a mixture containing 15g butyl acrylate, 10g ethyl orthosilicate and 1g A-171 for 15min, and stirred on a magnetic stirrer for 24h , Prepare modified nano-silica pre-emulsion. At 70° C., the modified nano-silica emulsion was added dropwise to 35 g of deionized water within 1.5 hours, and 10 g of potassium persulfate aqueous solution with a weight concentration of 1.5% was added, and the temperature was maintained for 40 minutes. At the same time, 0.4g DNS-86, 0.2g ANPEO 10 , 7.5g of butyl acrylate, 7.5g of methyl methacrylate, 0.5g of methacrylic acid, 0.5g of hydroxyethyl acrylate and 15g of deionized water are pre-emulsified for 5 minutes to prepare an acrylic pre-emulsion, and then drip within 1.5h After adding the acrylic ester pre-emulsion and 15 g of potassium persul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com