Method for rolling and forming TC11 titanium alloy thin-walled rings

A TC11, titanium alloy technology, applied in metal rolling and other directions, can solve the problems of small machining allowance, poor structural rigidity of thin-walled rings, alloy structure and performance influence, etc., to achieve high dimensional accuracy and save precious titanium alloy materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] To implement the rolling forming method of the TC11 titanium alloy thin-walled ring according to the present invention, equipment such as a forging heating furnace, a press, a ring rolling machine, and a manipulator are required.

[0034] The main chemical element content (percentage by weight) of the alloy is: 5.8% to 7.0% of Al, 2.8% to 3.8% of Mo, 0.8% to 2.0% of Zr, 0.2% to 0.35% of Si, 0.2% to 0.35% of Si, Fe content ≤ 0.25%, C content ≤ 0.10%, N content ≤ 0.05%, H content ≤ 0.012%, O content ≤ 0.15%, other elements individually ≤ 0.10% and the sum ≤ 0.40%, the balance being Ti .

[0035] The process steps of the alloy from the bar to the production of qualified thin-walled rings are as follows:

[0036] Step 1: Blank making.

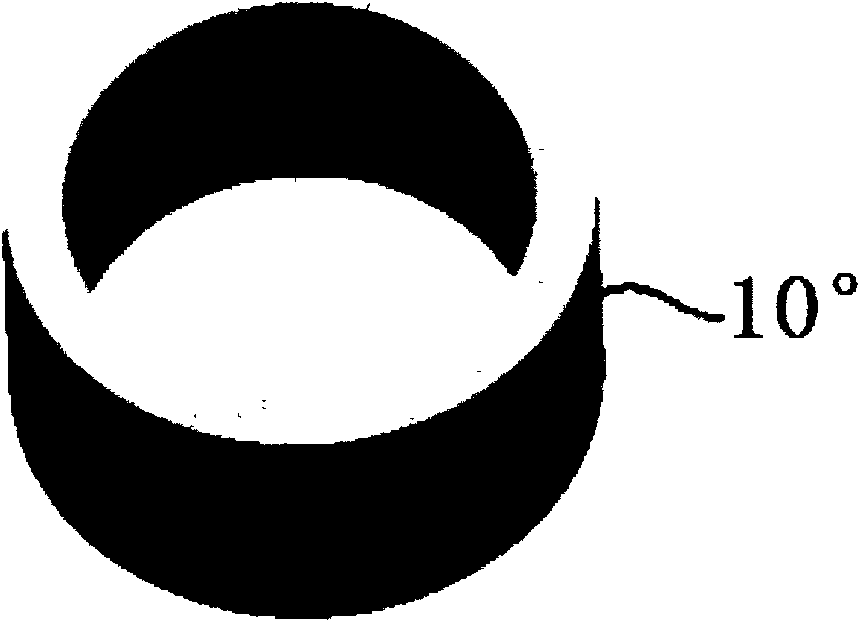

[0037] After heating, upsetting, punching, elongating, and pre-rolling the TC11 titanium alloy bar blanked according to the specification, a pre-rolled billet 10° is produced, and its shape is as follows: figure 1 shown.

[0038] Step 2:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com