Rolling and forming method for 0Cr25Ni20Mo2 stainless steel thin-wall ring

A technology of 0cr17ni12mo2 and stainless steel is applied in the field of rolling forming of 0Cr17Ni12Mo2 stainless steel thin-walled rings, which can solve problems such as unstable production, pre-rolled billet plastic instability, ring shape and size not up to design and use, etc., to save steel , The effect of high forming dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Implementing the roll forming method of the 0Cr17Ni12Mo2 stainless steel thin-walled ring according to the present invention needs to provide equipment such as forging heating furnace, press machine, ring rolling machine, manipulator.

[0032] The main chemical element content (percentage by weight) of the steel is: C content 0.08%, Mn content 2.00%, P content 0.045%, S content 0.030%, Si content 1.00%, Cr content 16.0%~18.0 %, Ni content is 10.0%-14.0%, Mo content is 2.00%-3.00%, N content is 0.10%, and the balance is Fe.

[0033] The process steps of the steel from the bar to the production of qualified thin-walled rings are as follows:

[0034] Step 1: Blank making.

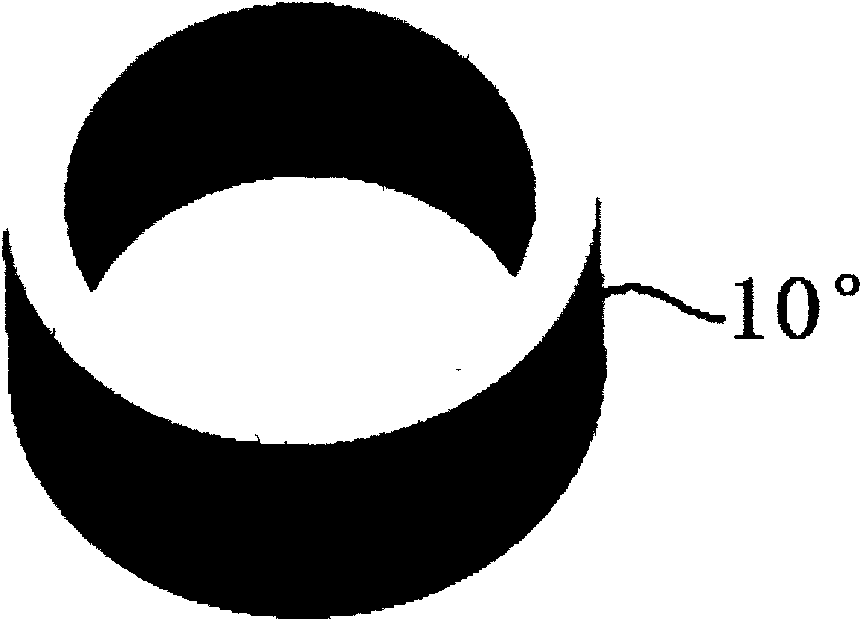

[0035] The 0Cr17Ni12Mo2 stainless steel bar blanked according to the specifications is heated, upset, punched, drawn, and pre-rolled to produce a pre-rolled billet 10°, and its shape is as follows: figure 1 shown.

[0036] Step 2: Install the computer.

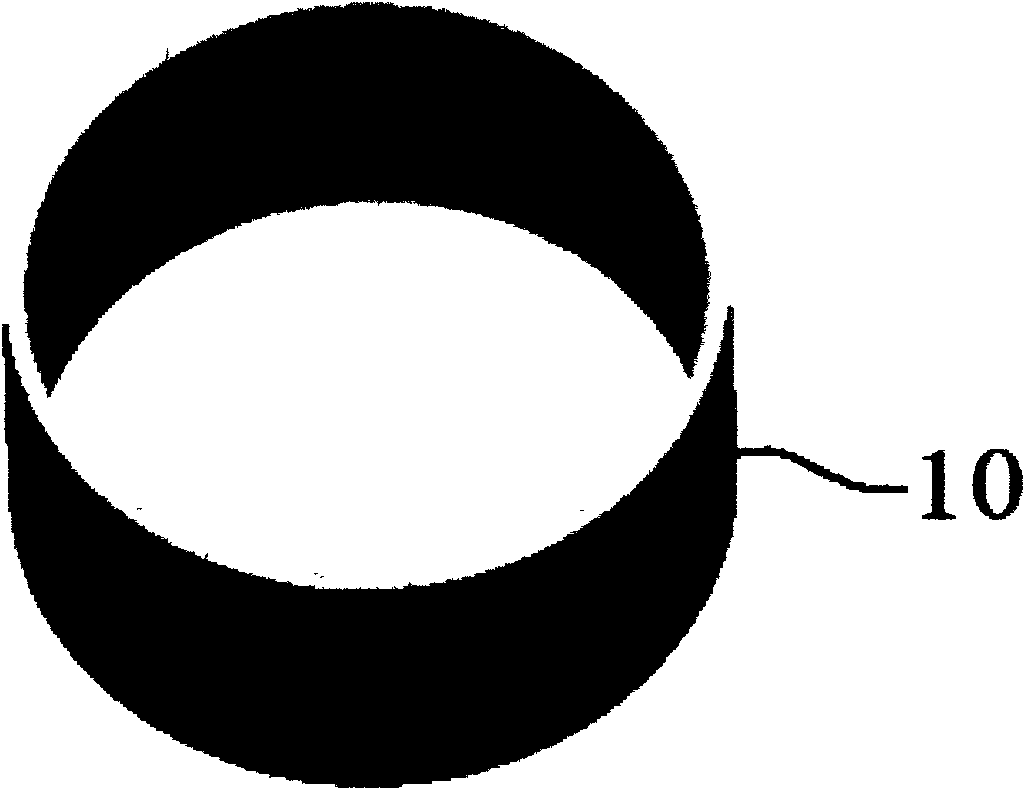

[0037] Such as figure 2 As shown, the pre-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com