Wide-temperature full methanation catalyst and preparation method thereof

A complete methanation and catalyst technology, applied in the field of wide temperature complete methanation catalyst and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

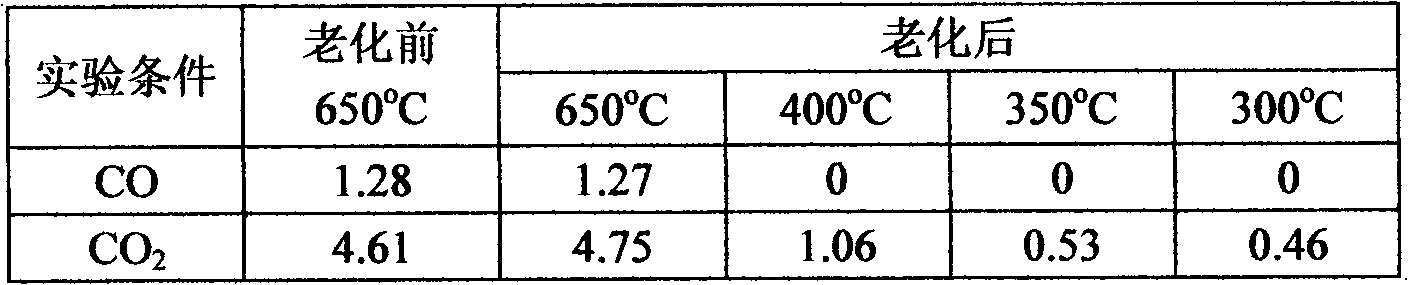

Image

Examples

Embodiment 1

[0072] Embodiment 1: Catalyst A

[0073] (1) Weigh 124.5g Ni(NO 3 ) 2 .6H 2 O, 223.5g Al(NO 3 ) 3 .9H 2 O, 15g La(NO 3 ) 3 .6H 2 O, 1M Zr(NO 3 ) 4 Solution 97.5mL, add deionized water to dissolve to 1000mL;

[0074] (2) Weigh 150g of urea, add 500mL of deionized water to dissolve;

[0075] (3) After mixing the solutions (1) and (2), add deionized water to 2000mL;

[0076] (4) Under stirring conditions, heat the solution to 90°C, keep the reaction for 40 hours, the pH rises from 2.3 to 4.5, and precipitation occurs, and the final pH is about 7;

[0077] (5) Filter the precipitate, wash twice with 1000mL deionized water; dry at 110°C for 12 hours; place the sample in a muffle furnace after drying, and roast at 500°C for 2 hours at a heating rate of 2°C / min; the resulting product is added with 3% Graphite and 2% cellulose were uniformly ground, shaped, and then calcined in a muffle furnace at 500° C. for 2 hours to form a catalyst precursor.

[0078] The obtained ca...

Embodiment 2

[0085] Example 2: Catalyst B

[0086] (1) Weigh 124.5g Ni(NO 3 ) 2 .6H 2 O, 223.5g Al(NO 3 ) 3 .9H 2 O, 15gLa(NO 3 ) 3 .6H 2 O, add deionized water to dissolve to 1000mL, under stirring conditions, and heat to 50°C;

[0087] (2) Measure 1M Zr(NO 3 ) 4 Solution 97.5mL was added to the mixed solution (1), and stirred for 20 minutes to form a mixed solution;

[0088] (3) Weigh 275g of NH 4 HCO 3 , add deionized water to form a 500mL solution, and then evenly drop it into the mixed solution (2) under the condition of vigorous stirring for 70 minutes; the pH is less than

[0089] 8. Keep the liquid temperature at 50°C and stir for 2 hours;

[0090] (4) filter the precipitate; wash twice with 1000mL deionized water; dry at 110°C for 12 hours;

[0091] After drying, the sample is placed in a muffle furnace, and the temperature is raised to 500°C at a heating rate of 2°C / min and roasted for 2 hours; the resulting product is shaped with 3% graphite and 2% cellulose, and ...

Embodiment 3

[0119] Embodiment 3: Catalyst F

[0120] (1) Weigh 71.5g Ni(NO 3 ) 2 .6H 2 O, 323g Al(NO 3 ) 3 .9H 2 O, 15g La(NO 3 ) 3 .6H 2 O, 1M Zr(NO 3 ) 4 Solution 97.5mL, add deionized water to dissolve to 1000mL;

[0121] (2) Weigh 160g of urea, add 500mL of deionized water to dissolve;

[0122] (3) After mixing the solutions (1) and (2), add deionized water to 2000mL;

[0123] (4) Under stirring conditions, heat the solution to 90°C, keep the reaction for 40 hours, the pH rises from 2.3 to 4.5, and precipitation occurs, and the final pH is about 7;

[0124] (5) Filter the precipitate, wash twice with 1000mL deionized water; dry at 110°C for 12 hours; place the sample in a muffle furnace after drying, and roast at 500°C for 2 hours at a heating rate of 2°C / min; the resulting product is added with 3% Graphite and 2% cellulose were uniformly ground, shaped, and then calcined in a muffle furnace at 500° C. for 2 hours to form a catalyst precursor.

[0125] The obtained catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com