Method for producing refined pure hawthorn extract tablets

A production method and tablet technology, which is applied in the field of processing fresh hawthorn pulp or concentrated hawthorn juice, can solve the problems that the health care or pharmacological effects of active ingredients of hawthorn cannot be well reflected, and the content of active ingredients of hawthorn is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. the production of primary hawthorn juice

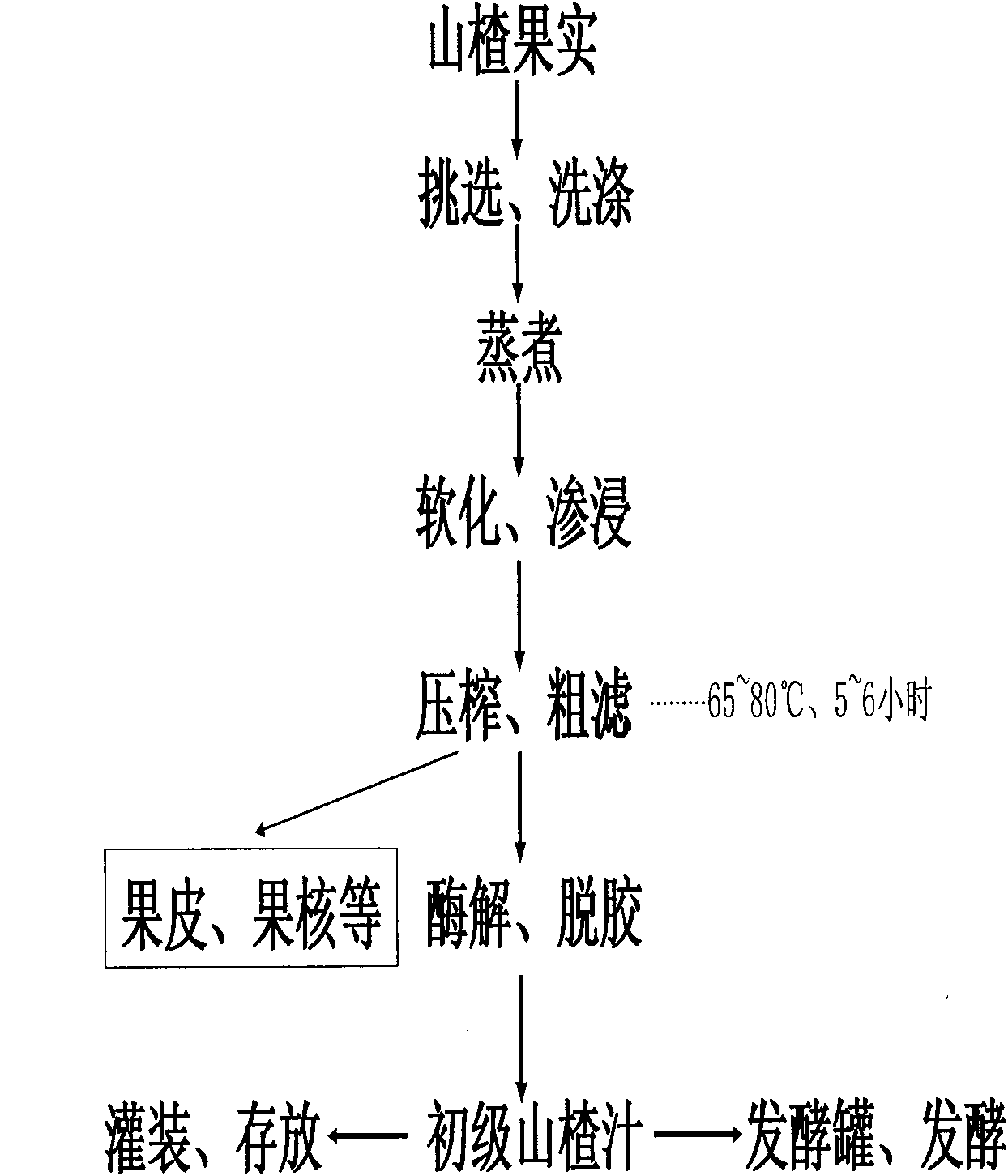

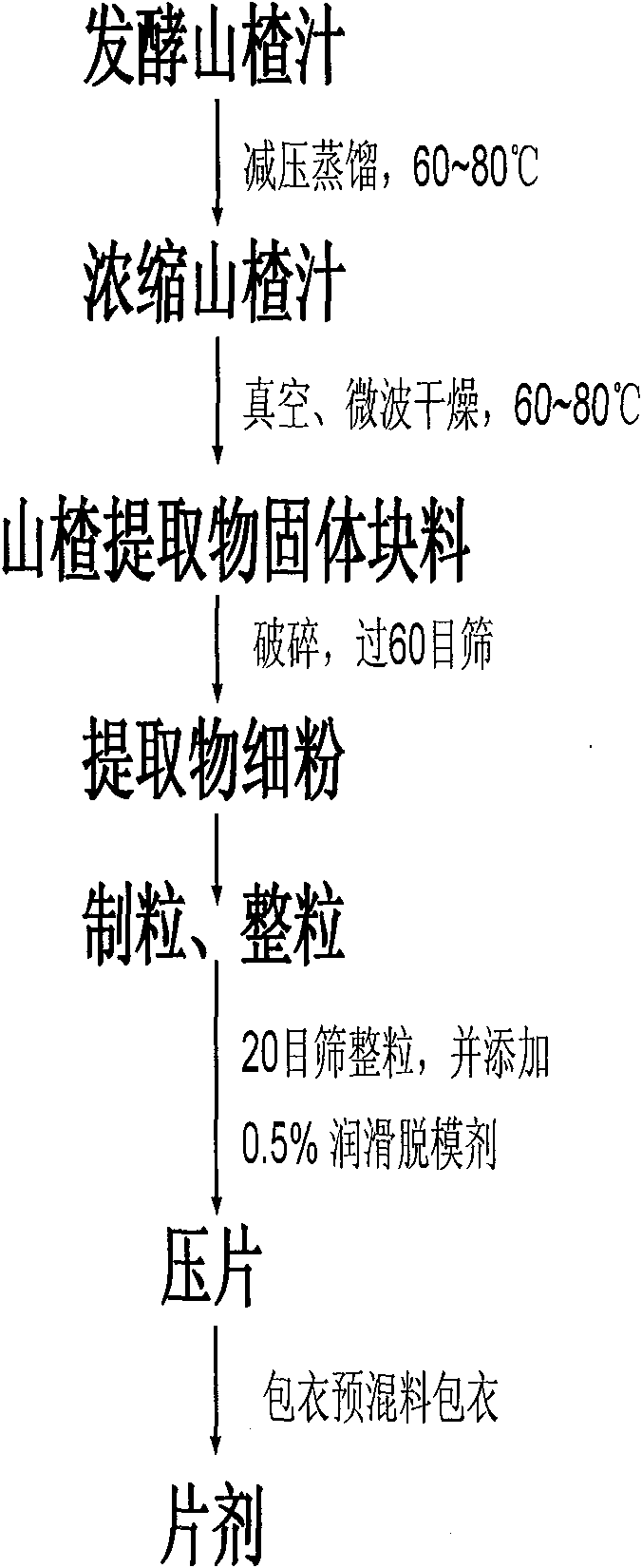

[0025] Using conventional water infiltration process, according to figure 1 The above steps can extract the soluble components of the hawthorn by pressing and extracting to obtain the original hawthorn juice, which is the special primary hawthorn juice in the description of this patent, which can be used for subsequent fermentation and processing.

[0026] Pick out the hawthorns that have deteriorated and infested with insects, wash to remove dirt such as sediment, and directly cook or crush the hawthorn fruit (the crushing treatment step can speed up the soaking speed and improve the dissolution of soluble solids). Add pure water to the hawthorn fruit (according to the weight ratio of hawthorn / water = 1 / 3-10), slowly heat and maintain at 65-80°C for about 4-5 hours to soak for about 4-5 hours, fully soften the hawthorn pulp, squeeze to obtain hawthorn juice and Remove insoluble solids (skin, core, etc.) by filtr...

Embodiment 2

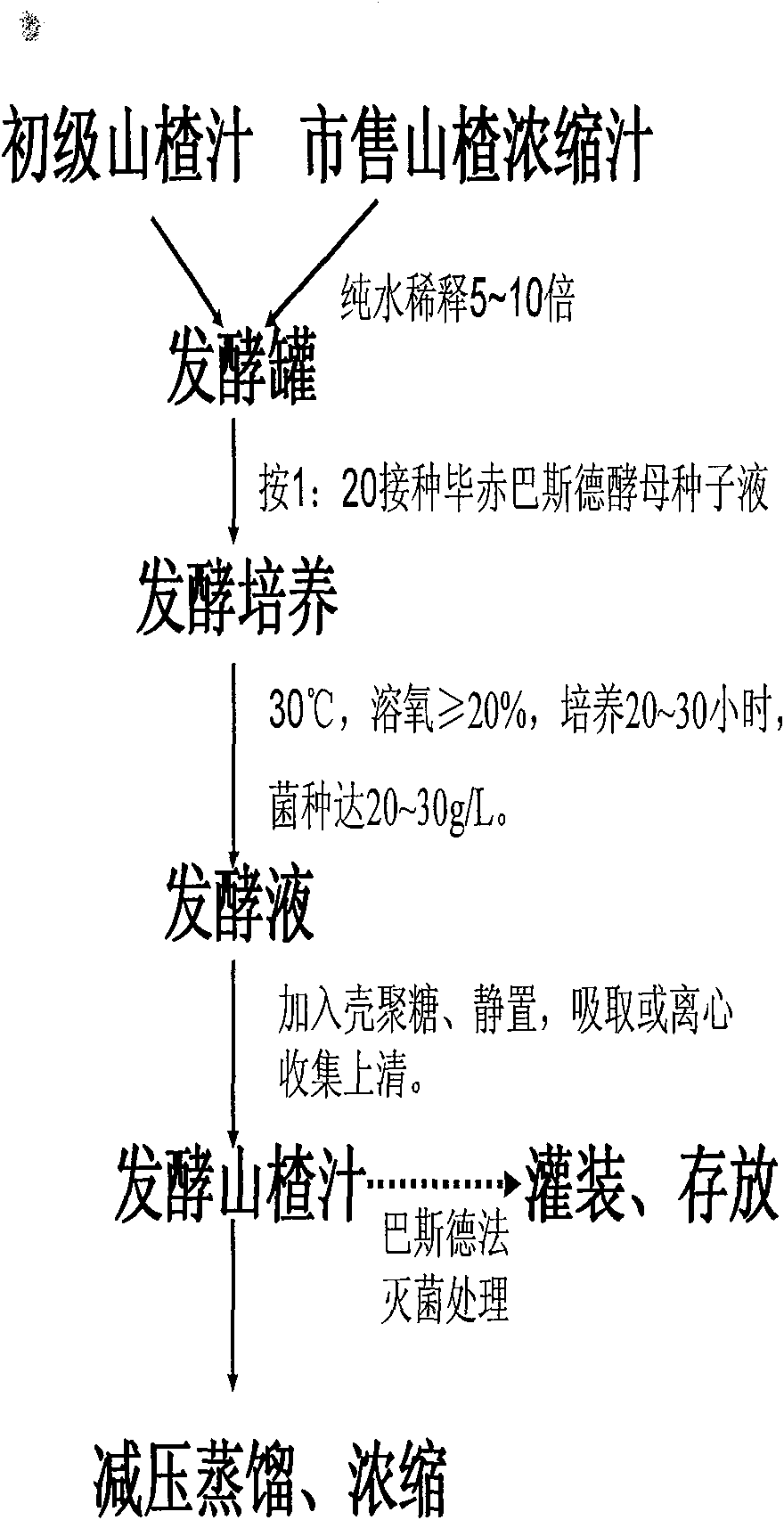

[0027] Embodiment 2. the production of fermented hawthorn juice

[0028] Primary hawthorn juice is rich in carbohydrates and nitrogen sources, but with a pH between 2.0 and 3.0, it is difficult for Saccharomyces cerevisiae and Aspergillus to grow in it, but Pichia pastoris can grow normally in it. Therefore, through a large number of comparative research experiments, we adopted the wild-type Pichia pastoris strain (X33, Invitrogen) as the strain for fermentation. The operation process is as follows:

[0029] Dilute the primary hawthorn juice 3 times with water, discharge it into the fermenter, and pasteurize the diluted primary hawthorn juice at 65-70°C for 60 minutes according to the standard operation procedure of Pichia pastoris fermentation, cool to 30°C and maintain it Under the temperature, according to 1:20 (seed liquid: diluted primary hawthorn juice, v / v), transfer to the Pichia pastoris seed liquid, set the stirring speed to 200 rpm, and the dissolved oxygen is not ...

Embodiment 3

[0030] Example 3. Determination of Total Flavonoids in Hawthorn Extract or Hawthorn Juice

[0031] Refer to the method for the determination of total flavonoids in hawthorn leaves in "Detection Methods of Health Food Functional Components" edited by Wang Guangya, China Light Industry Press (2002 edition P29-31) and "Chinese Pharmacopoeia" 2005 edition (P22-23). Rutin is used as a standard, and the amount of total flavonoids in the sample can be determined. Because the hawthorn juice obtained in this patent is all water-soluble extracts in hawthorn, and the water-insoluble components are very few, so the original assay method has been improved, and steps such as reflux and extraction have been omitted, and the reproducibility of the method is improved. Well, the assay is quick and easy.

[0032] The instruments and equipment used in the determination process mainly include desktop centrifuge, 751 type spectrophotometer, electronic balance (accuracy ≥ 0.1mg), sampler (Gilson), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com