Biomass vaporization gas-powder mixed combustor

A biomass and gasification gas technology, applied in the direction of burners, indirect carbon dioxide emission reduction, lighting and heating equipment, etc., can solve the problem of unstable ignition, failure to consider the combustion rate of gasification gas and semi-coke, high ash content in flue gas, etc. problems, to achieve the effect of ensuring flame stability, improving conversion pathways and utilization, and reducing ash corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

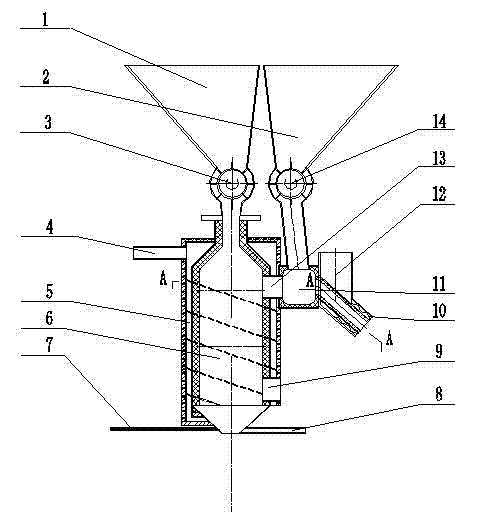

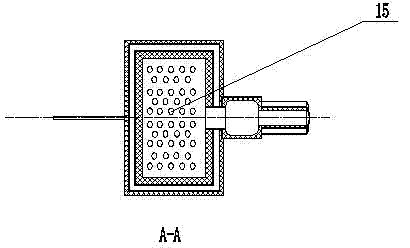

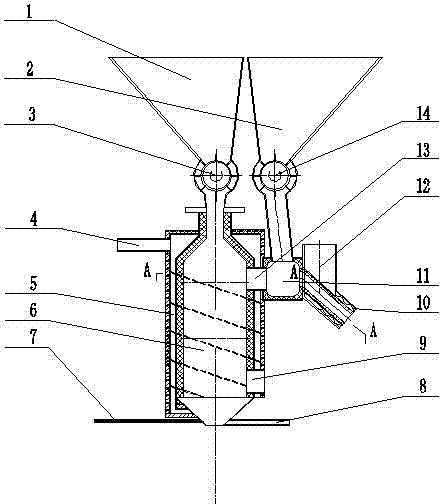

[0014] In the figure: 1 coarse material bin, 2 fine material bin, 3 primary feeder, 4 primary air inlet, 5 gasifier spiral jacket, 6 gasification chamber, 7 ash removal water inlet, 8 fine ash outlet, 9 coarse Ash outlet, 10 secondary air outlet with spiral, 11. gas powder mixing chamber, 12 secondary air inlet, 13 gasification gas outlet, 14 secondary feeder, 15 fire grate.

[0015] The biomass gasification gas-powder mixing burner includes two feeders and two silos, a primary feeder, a secondary feeder, a jacketed biomass gasification chamber and a gas-powder mixing chamber, and a primary air The flow part, the secondary air flow part. The technical point is: the biomass fuel in the two silos enters the biomass gasification chamber and the gas powder mixing chamber respectively through the primary feeder and the secondary feeder, and the jacket of the biomass gasificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com