Novel operating device of double-disk friction press

A friction press and control device technology, applied in the field of presses, can solve the problems of increasing production costs, reducing production efficiency, and easy wear of parts, and achieving the effects of reducing maintenance costs, improving production efficiency, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

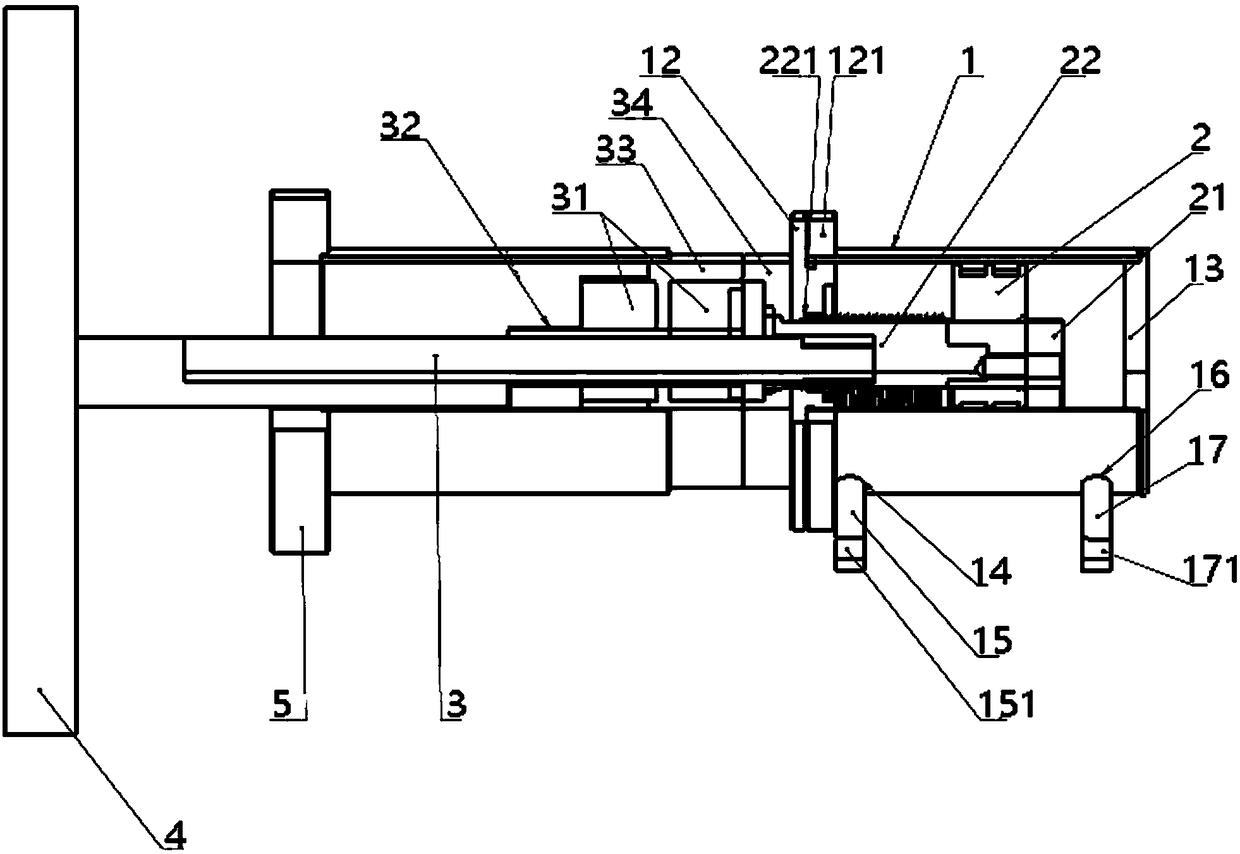

[0023] This embodiment provides a novel manipulation device for a double-disk friction press, such as figure 1 shown, including:

[0024] Cylinder, the cylinder includes a cylinder barrel 1, a piston 2 installed in the cylinder barrel 1; the piston 2 is fixedly connected to the piston shaft 22 through the piston connecting shaft 21, and the front end of the cylinder barrel 1 is provided with a front cover of the operating cylinder 12. The rear end is provided with the rear cover 13 of the operating cylinder; the piston shaft 22 is covered with a pressure spring 221, one end of the pressure spring 221 is fixed on the front cover 12 of the operating cylinder, and the other end is fixed on the piston 2 Above; the frontmost side wall of the cylinder 1 is connected to the pipeline B15 through the hole B14, and the pipeline B15 is provided with a solenoid valve B151 to control its opening and closing, and the rearmost sidewall of the cylinder 1 is connected to the pipeline A17 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com