A kind of photocatalyst and its preparation method and application

A technology of photocatalysts and oxides, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of small wavelength range and easy recombination, so as to improve photocatalytic efficiency and high catalytic efficiency The effect of efficiency and fast catalytic speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A photocatalyst, which is a metal compound obtained by compounding a metal oxide and a metal sulfide by mass percentage, that is, metal oxide: metal sulfide in a ratio of 99%: 1%;

[0049] The metal oxide is zinc oxide;

[0050] The metal sulfide is molybdenum disulfide;

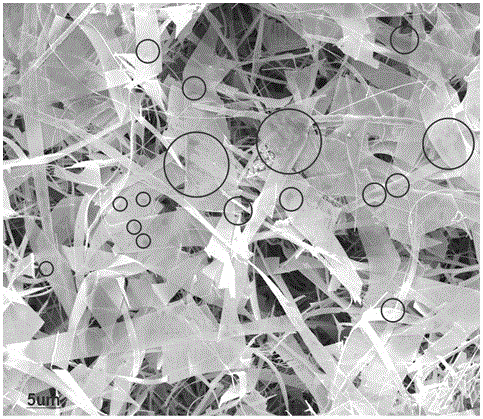

[0051] The zinc oxide is an irregular nanosheet structure, the size of the nanosheet structure is 10-900nm, and the thickness is 10-50nm;

[0052] The molybdenum disulfide is an irregular nano sheet structure, the size of the nano sheet structure is 10-100nm, and the thickness is 0.6-5nm.

[0053] The preparation method of above-mentioned photocatalyst specifically comprises the steps:

[0054] 1. Preparation of zinc oxide nanosheets by traditional chemical vapor deposition method

[0055] (1) Fully grind zinc oxide powder and graphite powder with equal mass ratio, then add 5% phosphorus pentoxide, and then put it into a quartz boat;

[0056] (2), Al coated with Au film 2 o 3 The substrate is pl...

Embodiment 2

[0075] A photocatalyst, which is a metal compound obtained by compounding a metal oxide and a metal sulfide by mass percentage, that is, metal oxide: metal sulfide in a ratio of 99.9%: 0.1%;

[0076] It is a composite structure of metal oxide and metal sulfide. It is a photocatalyst. It is a composite structure of metal oxide and metal sulfide. It is mixed according to the mass ratio of metal oxide and metal sulfide at 99.9%, stirred for 30 minutes, and ultrasonicated for 30 minutes. , with a power of 200W, a drying temperature of 100°C, and a drying time of 24 hours to obtain the photocatalyst;

[0077] The metal oxide is zinc oxide;

[0078] The metal sulfide is molybdenum disulfide;

[0079] The zinc oxide is an irregular nanosheet structure, the size of the nanosheet structure is 10-900nm, and the thickness is 10-50nm;

[0080] The molybdenum disulfide is an irregular nano sheet structure, the size of the nano sheet structure is 10-100nm, and the thickness is 0.6-5nm.

...

Embodiment 3

[0083] A photocatalyst, which is a metal compound obtained by compounding metal oxide and metal sulfide in terms of mass percentage, that is, metal oxide: metal sulfide ratio of 99.99%: 0.01%;

[0084] The metal oxide is zinc oxide;

[0085] The metal sulfide is molybdenum disulfide;

[0086] The zinc oxide is an irregular nanosheet structure, the size of the nanosheet structure is 10-900nm, and the thickness is 10-50nm;

[0087] The molybdenum disulfide is an irregular nano sheet structure, the size of the nano sheet structure is 10-100nm, and the thickness is 0.6-5nm.

[0088] The preparation method of above-mentioned a kind of photocatalyst, with embodiment 1.

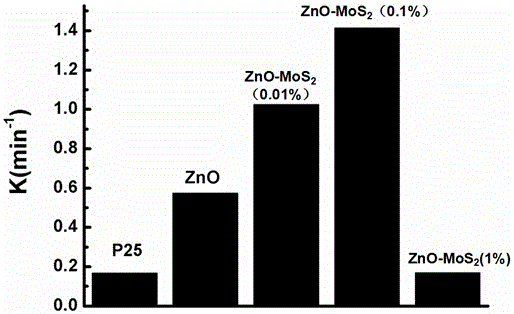

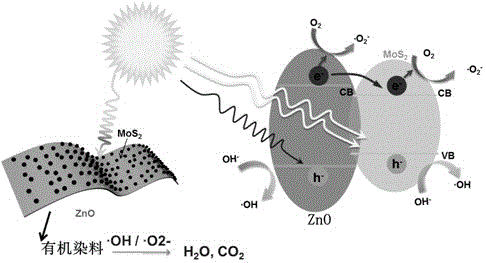

[0089] The ZnO-MoS obtained in the above-mentioned examples 1-3 2 The absorption curves of the composite photocatalyst and pure ZnO and P25 solid powder measured by UV-Vis spectrometer (manufacturer: Shimadzu, model: Shimadzu UV-2600) at room temperature are as follows: Figure 5 shown, from Figure 5 It can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com