Method for deacidification of alkylation reaction product

A technology of alkylation reaction and deacidification method, applied in the field of deacidification of alkylation reaction products, can solve problems such as system corrosion and instability of settlers, achieve high mechanical strength, reduce the amount of alkali and the amount of waste water generated , the effect of facilitating interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

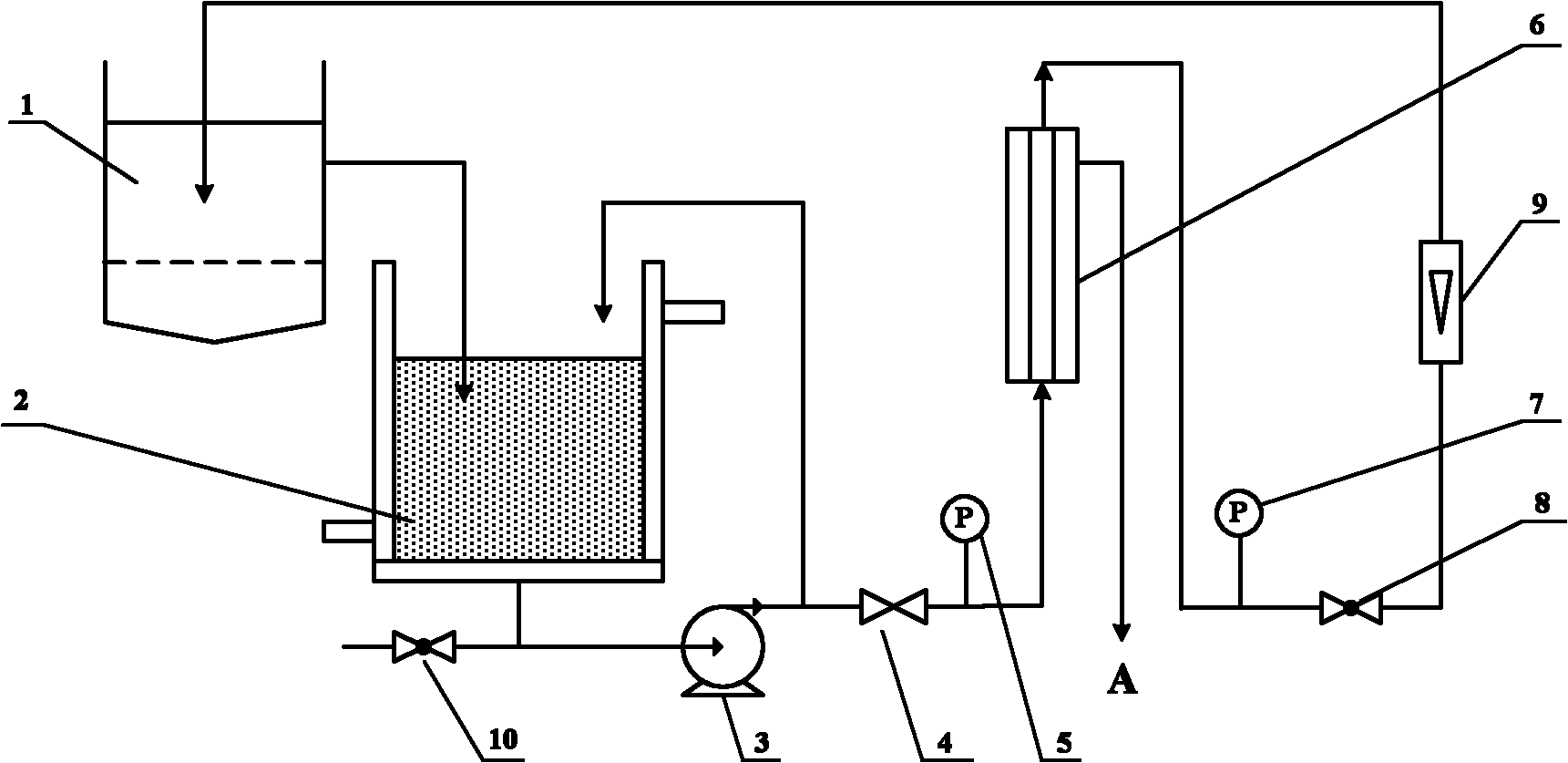

[0045] use figure 1 The process flow diagram shown.

[0046] A tubular ceramic membrane with α-alumina as the support layer and zirconia as the separation layer is selected, with an average pore size of 0.05 μm, modified with hexadecyltrimethoxysilane. The specific modification method is as follows: soak the ceramic membrane in ethanol dissolved in hexadecyltrimethoxysilane for 4 hours, wash it repeatedly with ethanol for 5 times, and finally dry it in an oven at 120°C for 3 hours. The surface contact angle of the rear ceramic membrane is 140°.

[0047] Using the deacidification method of the alkylation reaction product described in the present invention, the oil / sulfuric acid mixed emulsion is separated. After the 5L mixed emulsion was left to stand for 4 hours, the upper liquid was poured into the feed tank; the oil / sulfuric acid mixture in the feed tank was injected into the membrane module equipped with a surface-modified ceramic membrane using a pump, and the operating ...

Embodiment 2

[0049] use figure 1 The process flow diagram shown.

[0050] During the production process of petrochemical plants, a large amount of waste oil containing sulfuric acid will be produced. The main component of this waste oil is petroleum, but due to the large amount of sulfuric acid, it cannot be used directly. If the sulfuric acid component can be removed, the remaining petroleum component can still be utilized.

[0051] Use the deacidification method of the alkylation reaction product described in the present invention to separate sulfuric acid-containing petroleum. The support layer is β-alumina, and the separation layer is a tubular ceramic membrane of alumina. The average pore size is 0.2 μm, and octadecane is used. base trichlorosilane modification, the remaining modification steps are the same as in Example 1, the contact angle of water droplets on the surface of the modified ceramic membrane is 130°; the operating temperature is 40°C, and other operations are the same ...

Embodiment 3

[0053] use figure 1 The process flow diagram shown.

[0054] A large amount of waste oil will be produced in the production of propylene oxide. The current waste oil separation device often causes acidic water phase to enter the waste oil tank, which affects the quality of waste oil products and increases the corrosion of pipelines and equipment.

[0055] Use the deacidification method of the alkylation reaction product of the present invention to separate the propylene oxide production waste oil containing acidic water. The support layer is α-alumina, and the separation layer is a tubular ceramic membrane of titanium oxide. The average pore size is 0.05 μm, modified with n-butyldimethylchlorosilane, soaked for 10 hours, the remaining modification steps are the same as in Example 1, the contact angle of water droplets on the surface of the modified ceramic membrane is 95°; the operating pressure is 0.03MPa, the feed liquid The flow rate is 0.3L / min, that is, the membrane surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com