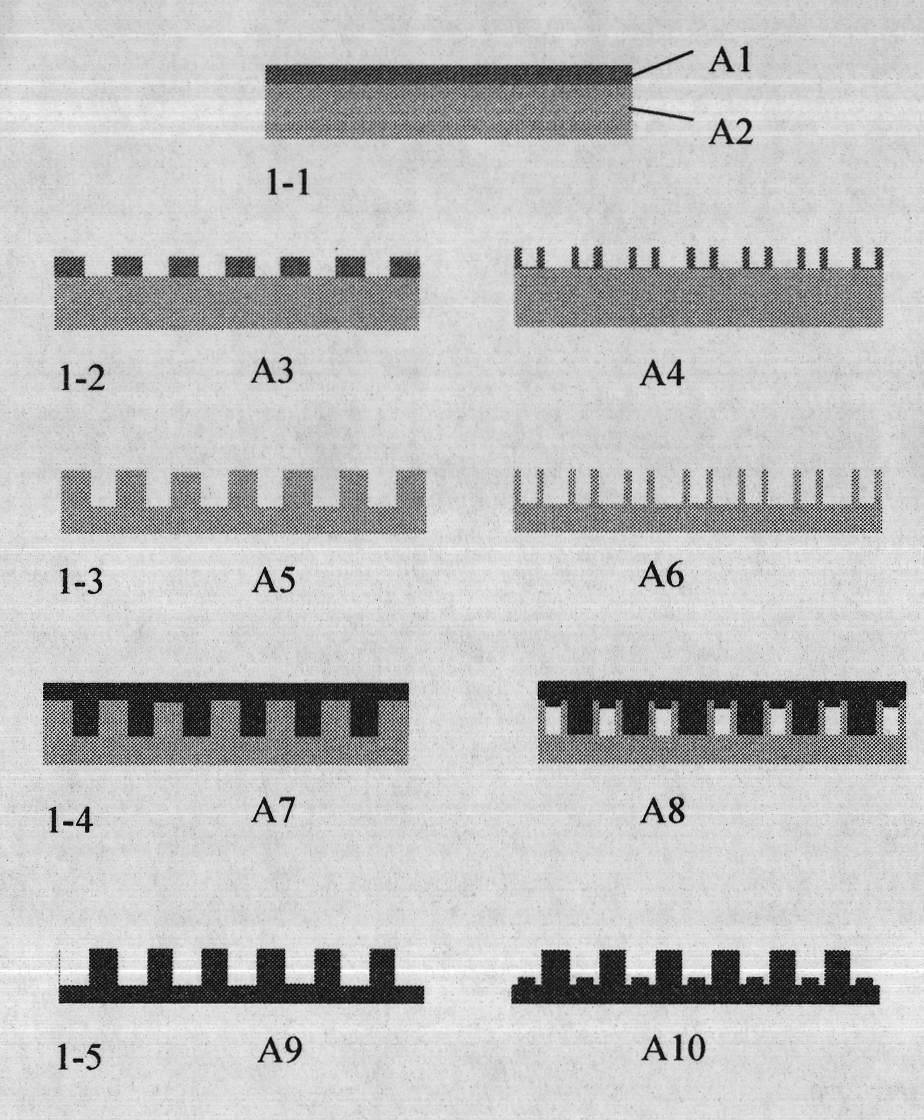

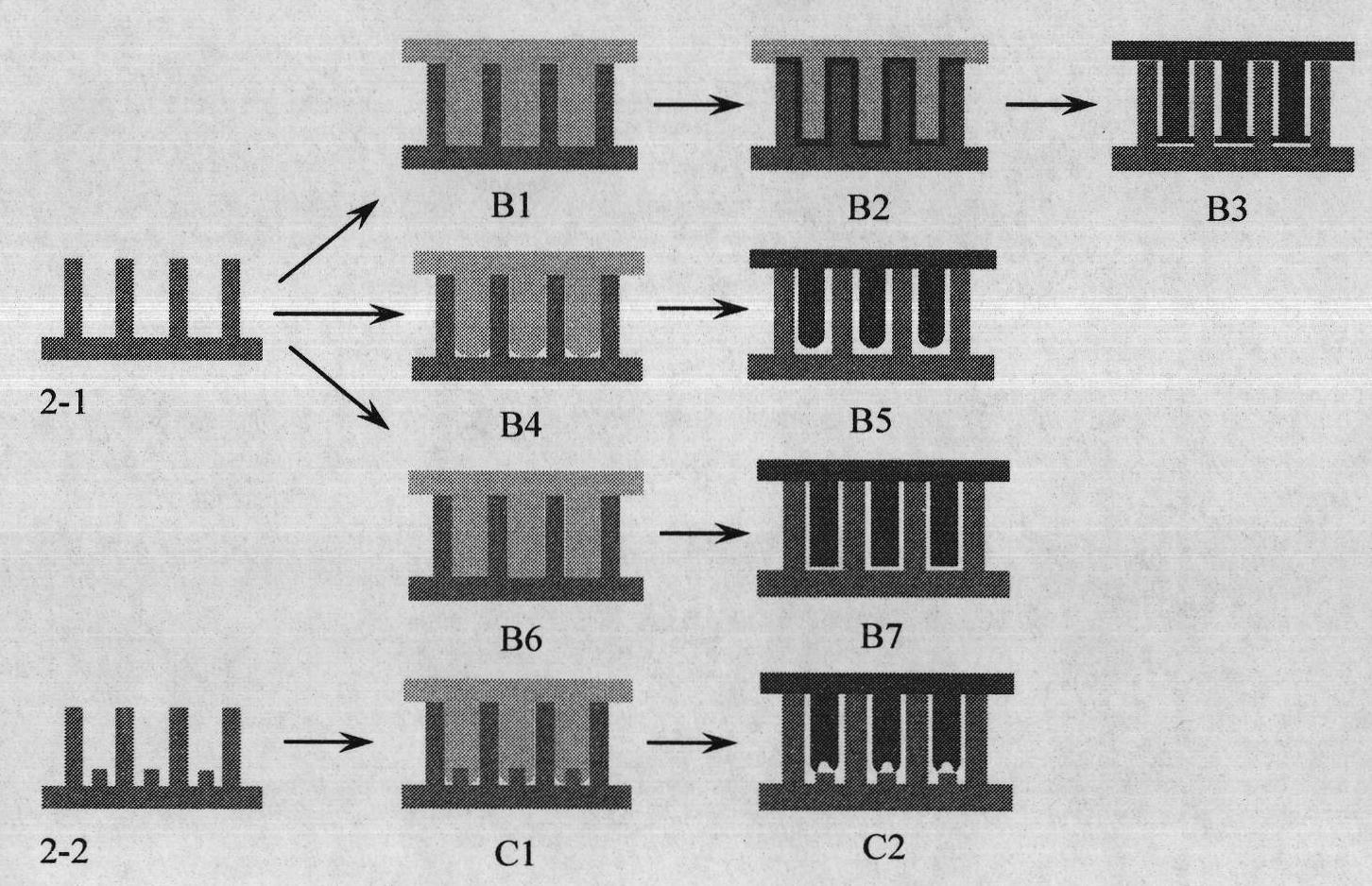

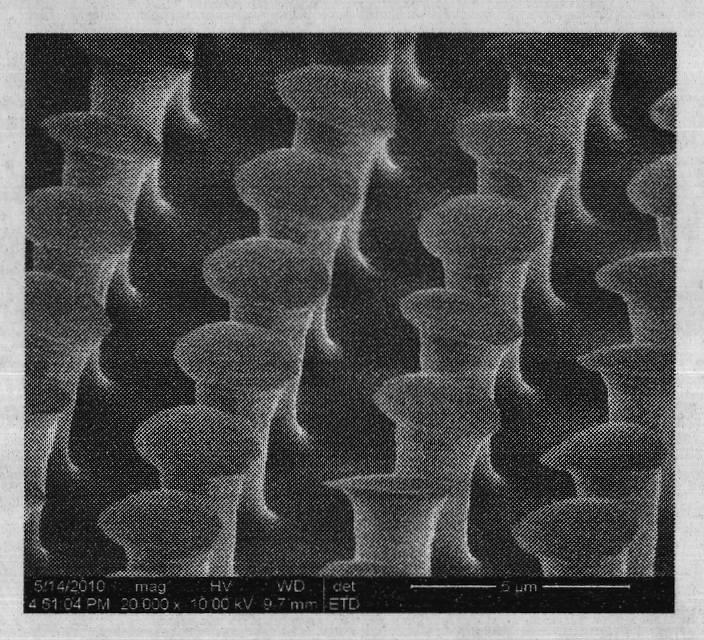

Method for preparing bionic adhesion arrays with different top end structures

An array and biomimetic technology, applied in the field of biomimetic adhesion array preparation, can solve the problems of single, complex and difficult operation of the top shape, and achieve the effect of broadening the scope of application and enriching research methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Sequentially wash the silicon substrate with concentrated sulfuric acid, rinse with deionized water, and dehydrate and bake to remove pollutants on the surface of the silicon substrate; remove water vapor, make the surface of the substrate change from hydrophilic to hydrophobic, and enhance Adhesion to the surface.

[0027] (2) Using a mask plate with hexagonally arranged solid chromium dots, the diameter of the chromium dots is 3 microns, and the pitch is 3 microns, and a photoresist mask pattern is obtained on the surface of the silicon substrate through an ultraviolet lithography process.

[0028] (3) Inductively coupled plasma etching is performed on the silicon substrate with a photoresist mask to obtain a micron column array, the column diameter is 3 microns, the pitch is 3 microns, the length (height) is 8 microns, and hexagonal arrangement.

[0029] (4) A soft template (template-1) with a micro-hole array structure was prepared by polydimethylsiloxane pourin...

Embodiment 2

[0032] Cover the water-soluble polyurethane (PU) material directly on the template-1, put it into the oven for drying and curing, the curing temperature is 40°C, and the curing time is 10 hours. Finally, the mold is demoulded to obtain the bionic micro-structure adhesion with the shape of the arc-shaped top array.

Embodiment 3

[0034] Cover the dimethylformamide solution of polymethyl methacrylate (PMMA) directly on the template-1, put it in an oven to dry and cure, the curing temperature is 60°C, and the curing time is 15 hours, and finally demolded to obtain a flat top Topography of Adhesive Arrays of Bioinspired Microstructures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com