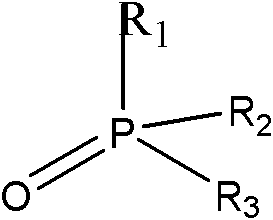

Multifunctional flame retardant as well as preparation and application thereof

A multi-functional, flame retardant technology, applied in textiles and papermaking, chemical instruments and methods, organic chemistry, etc., can solve problems such as strong flammability, limited use range, formaldehyde release, etc., and achieve good synergistic flame retardancy and soap resistance Good wash fastness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

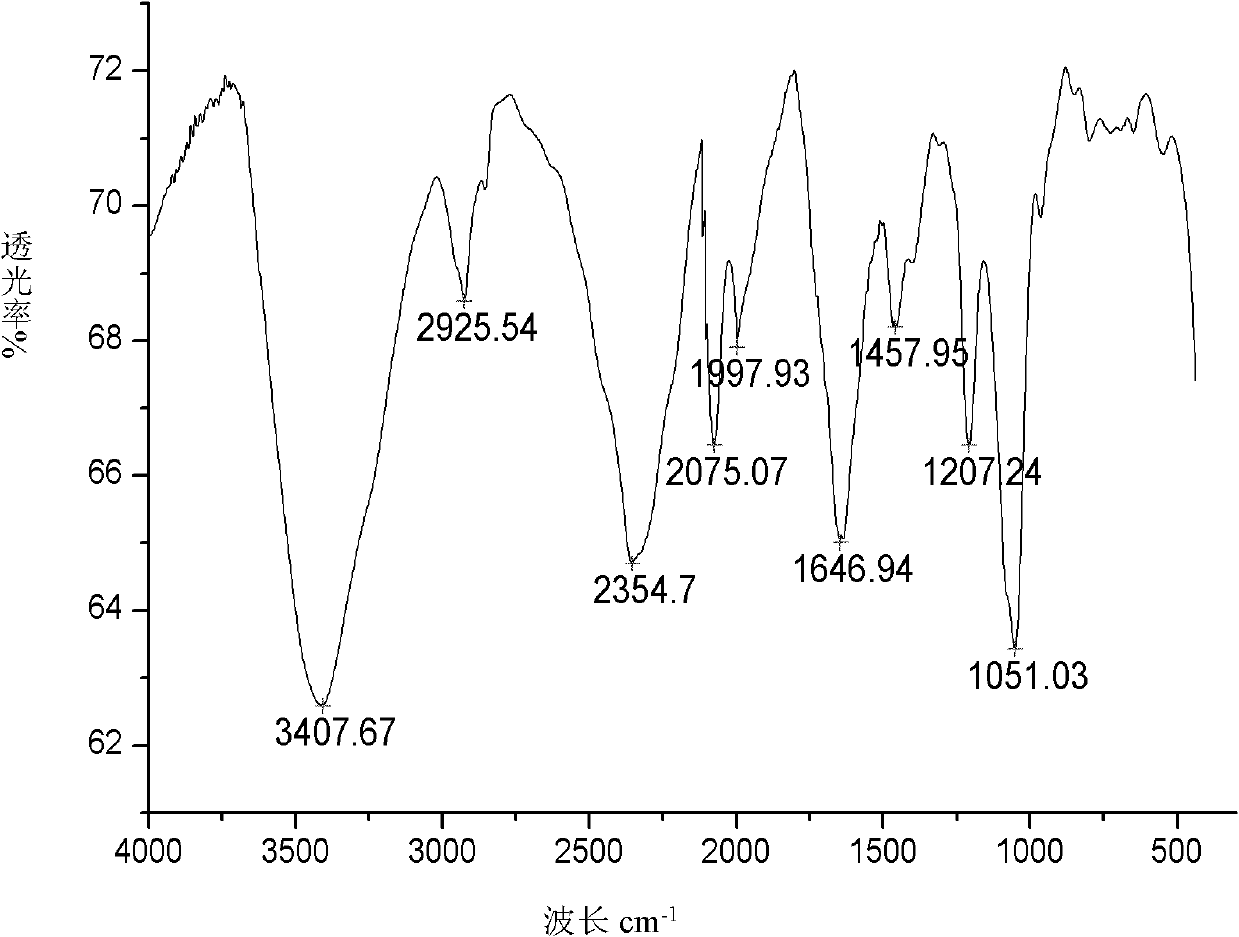

[0037] Take a dry 500ml four-necked flask, and use dry nitrogen to remove the air therein. Add 11.41 ml (0.125 mol) of phosphorus oxychloride, 54.21 ml (0.375 mol) of triethylamine (for absorbing hydrogen chloride produced by the reaction), and 50 ml of dry THF into a four-necked flask. Add 5.06ml (0.125mol) of anhydrous methanol and 50ml of dry THF into a 125ml separatory funnel. Cool the reaction system to below 5°C with an ice-salt bath, and then gradually add methanol in THF dropwise to the flask. During the whole dropping process, the temperature of the system should be kept below 5°C, and it should be carried out under nitrogen protection and mechanical stirring. After the dropwise addition, a condensing reflux device was installed, and the reactor was placed in a water bath at 35° C., mechanically stirred under the protection of nitrogen, and refluxed for 3 hours. Then lower the temperature of the reaction system to below 5°C, take another 125ml separatory funnel, add...

Embodiment 2

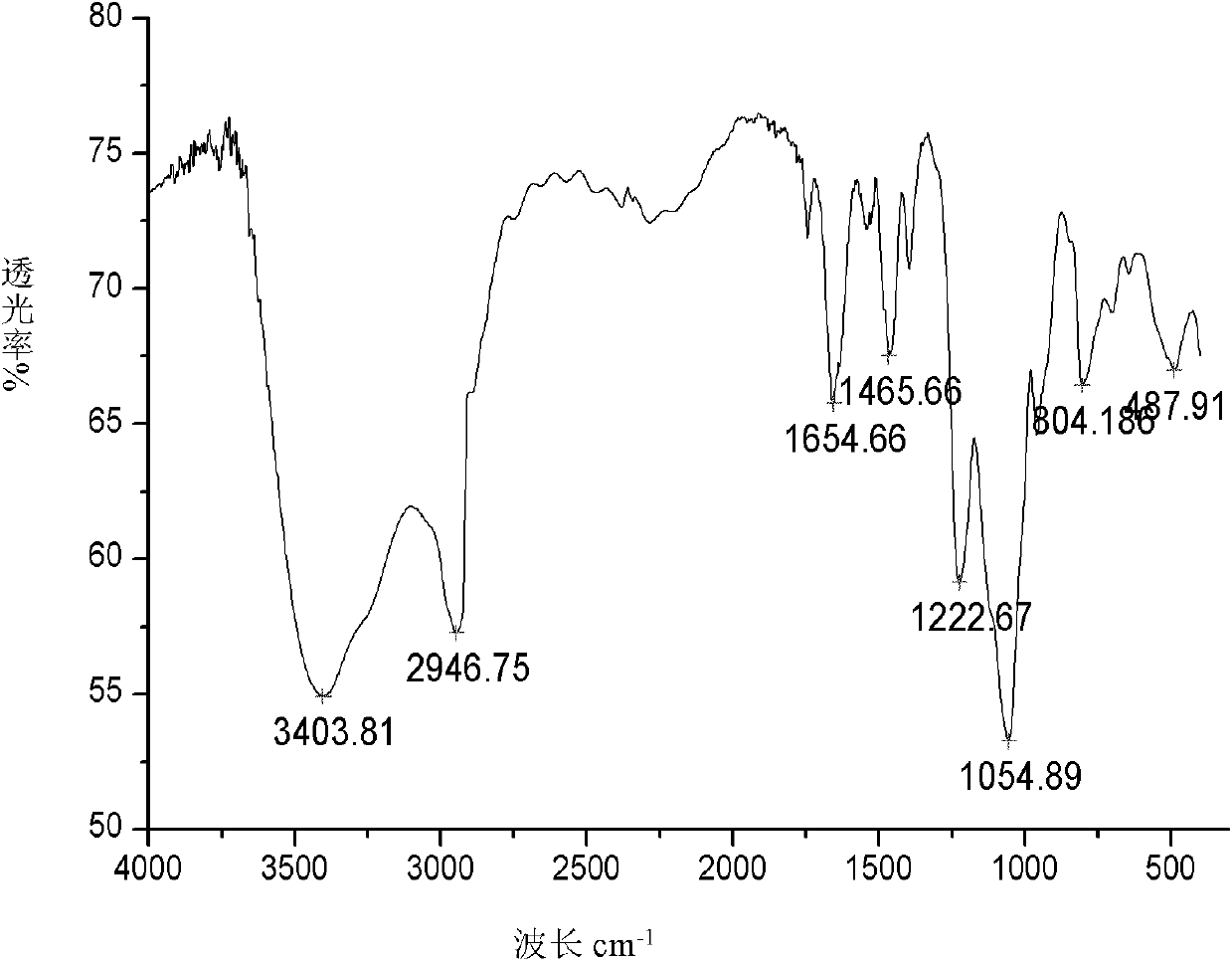

[0041] The reaction conditions of this example are basically the same as in Example 1, wherein the intake of anhydrous methanol is changed to 10.12ml (0.25mol), and the intake of gamma-aminopropyltriethoxysilane is changed to 29.20ml (0.125mol). was 74%. The obtained product II is light yellow viscous liquid, which is soluble in organic solvents such as water and THF. The infrared spectrum of product II is shown in image 3 .

Embodiment 3

[0043] The reaction conditions of this example are basically the same as in Example 1, wherein the feed ratio of phosphorus oxychloride to γ-aminopropyltriethoxysilane is 1:3, which is 11.41ml (0.125mol) and 87.60ml (0.375mol) respectively. ), the one-step reaction is completed, and the reaction yield is 74%. The obtained product III is a yellow viscous liquid, soluble in water, ethanol, THF and other organic solvents. The infrared spectrum of product III is shown in Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com