Surface treatment method of tin-plated steel plate

A tin-plated steel plate and surface treatment technology, applied in the field of steel parts, can solve the environmental hazards of waste gas and waste liquid, etc., and achieve the effects of excellent mechanical properties and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

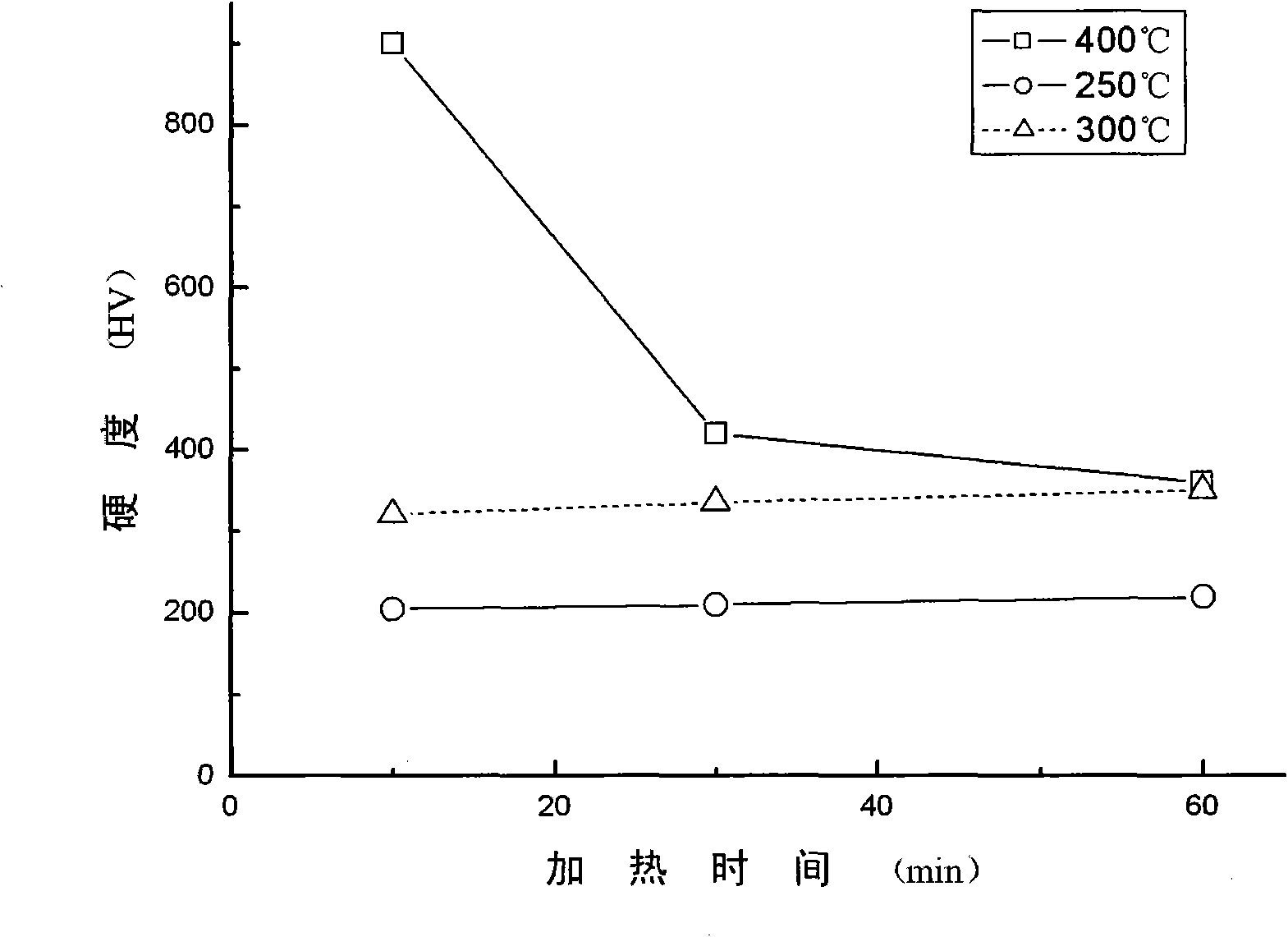

[0015] using H 3 PO 4 and Sn 4 The 50×50mm tinned steel plate electrolytically treated with Cl solution is used as the tinned steel plate substrate, and the tin film thickness is about 5 μm; first, the tinned steel plate substrate is placed in the sputtering treatment chamber, and the radio frequency magnetron Sputtering, where the sputtering parameters are target palladium diameter 0.1m, pure argon sputtering atmosphere 0.3Pa, RF power 100W, to obtain about 0.7μm coating; then put the tinned steel plate coated with palladium in the muffle furnace, Heat treatment is carried out under the temperature of 250 ℃, and treatment time is respectively 10min, 30min, 60min, obtains the steel part after the present invention is processed; The steel part after processing is carried out stability test, test result shows and does not carry out heat treatment steel part Parts are compared; the processed steel parts are tested for hardness with a Vickers hardness tester, and the test result...

Embodiment 2

[0017] using H 3 PO 4 and Sn 4 The 50×50mm tinned steel plate electrolytically treated with Cl solution is used as the tinned steel plate substrate, and the tin film thickness is about 5 μm; first, the tinned steel plate substrate is placed in the sputtering treatment chamber, and the radio frequency magnetron Sputtering, where the sputtering parameters are target palladium diameter 0.1m, pure argon sputtering atmosphere 0.3Pa, RF power 100W, to obtain about 0.7μm coating; then put the tinned steel plate coated with palladium in the muffle furnace, Heat treatment is carried out under the temperature of 300 ℃, and treatment time is respectively 10min, 30min, 60min, obtains the steel part after the present invention process; The steel part after treatment is carried out stability test, test result shows and does not carry out heat treatment steel part Parts are compared; the processed steel parts are tested for hardness with a Vickers hardness tester, and the test results are ...

Embodiment 3

[0019] using H 3 PO 4 and Sn 4 The 50×50mm tinned steel plate electrolytically treated with Cl solution is used as the tinned steel plate substrate, and the tin film thickness is about 5 μm; first, the tinned steel plate substrate is placed in the sputtering treatment chamber, and the radio frequency magnetron Sputtering, where the sputtering parameters are target palladium diameter 0.1m, pure argon sputtering atmosphere 0.3Pa, RF power 100W, to obtain about 0.7μm coating; then put the tinned steel plate coated with palladium in the muffle furnace, Heat treatment is carried out under the temperature of 400 ℃, and treatment time is respectively 10min, 30min, 60min, obtains the steel part after the present invention process; The steel part after treatment is carried out stability test, and test result shows that the steel part that does not carry out heat treatment Parts are compared; the processed steel parts are tested for hardness with a Vickers hardness tester, and the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com