Bacterial cellulose-inorganic nanoparticle hybrid membrane and preparation method thereof

A technology of inorganic nanoparticles and bacterial cellulose, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as high energy consumption and environmental pollution, achieve mild synthesis conditions, simple synthesis process, good The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Test strain: Glucoacetobacter xylinum 1.1812, purchased from Institute of Microbiology, Chinese Academy of Sciences

[0023] 2. Test method

[0024] Slant medium: glucose 100g, yeast powder 10g, calcium carbonate 20g, agar 20g, deionized water 1000mL, pH value 6.8, sterilized at 121°C for 20min.

[0025] Seed medium: 2% glucose, 0.5% peptone, 0.5% yeast powder, 0.68% disodium hydrogen phosphate dodecahydrate, 0.12% citric acid monohydrate, 0.50% magnesium sulfate heptahydrate, pH 6.0, sterilized at 121°C for 20 minutes .

[0026] Fermentation Medium: The fermentation medium has the same composition as the seed medium.

[0027] With a 10% inoculation amount, the well-grown seed culture solution was inserted into an Erlenmeyer flask containing 100 mL of Acetobacter xylinum fermentation culture solution, and then 4 g of titanium precursor—di(2-hydroxypropionic acid) dihydrogen dihydroxide was added. The 50% aqueous solution of ammonium titanium, in a biochemical incu...

Embodiment 2

[0030] 1. The test bacterial classification and medium formula are the same as in Example 1

[0031] 2. Test method

[0032] TiO 2 Sol preparation

[0033] Add 5mL of titanium precursor—a 50% aqueous solution of di(2-hydroxypropionic acid) diammonium titanium hydroxide and 25mL of deionized water into the hydrothermal kettle, heat it to 140°C in a muffle furnace, and keep the temperature at 24°C. hours, and then naturally cooled to room temperature to obtain TiO 2 Sol.

[0034] 4mL TiO obtained by hydrothermal synthesis 2 The sol was added to an Erlenmeyer flask filled with 100 mL of medium, and then 10 mL of seed culture solution that had been cultivated for 2 days was added, and cultured in a biochemical incubator at 30°C for 7 days. The cultured basement membrane was taken out and washed with deionized water until milky white, so as to remove the remaining medium and water-soluble polysaccharides. Then, it was soaked in 1% NaOH solution for 48 hours to remove the bact...

Embodiment 3

[0037] The preparation process is the same as in Example 1, except that di(2-hydroxypropionic acid) diammonium hydroxide titanium is replaced by sodium silicate solution, and the concentration of sodium silicate in the medium is 1 mg / mL, and finally bacterial cellulose- SiO 2 nanohybrid film.

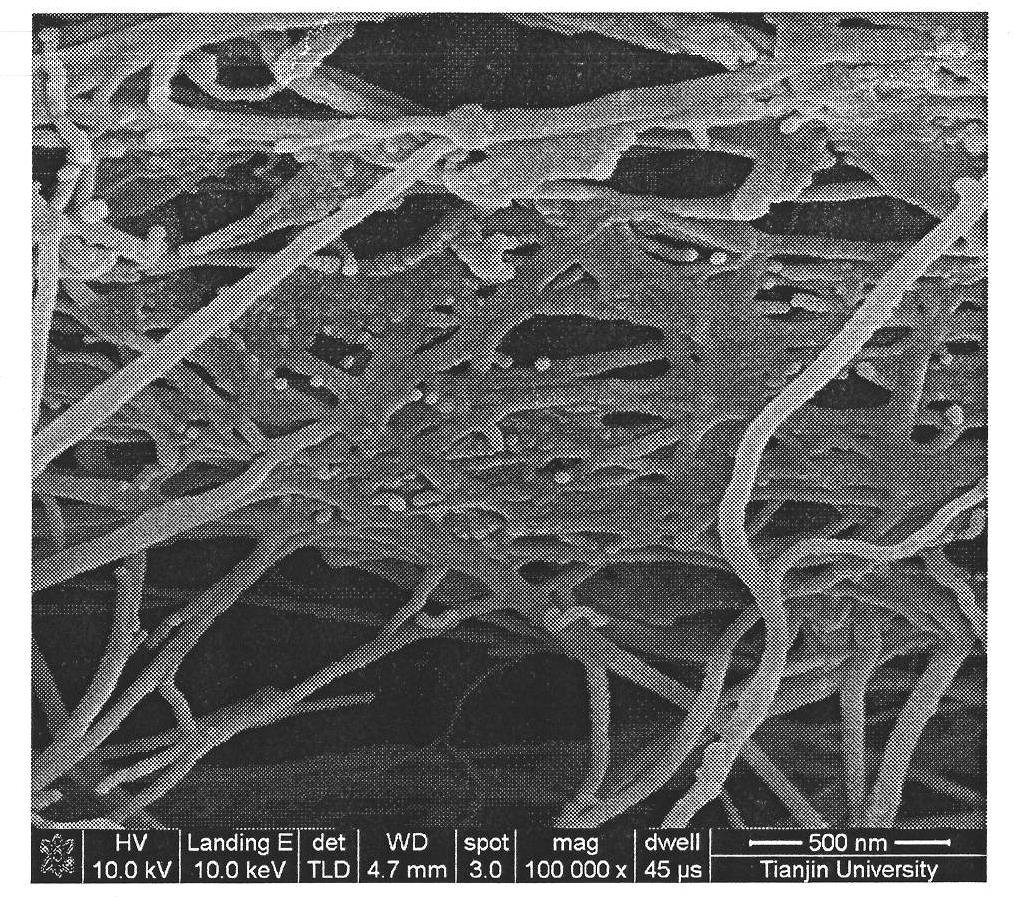

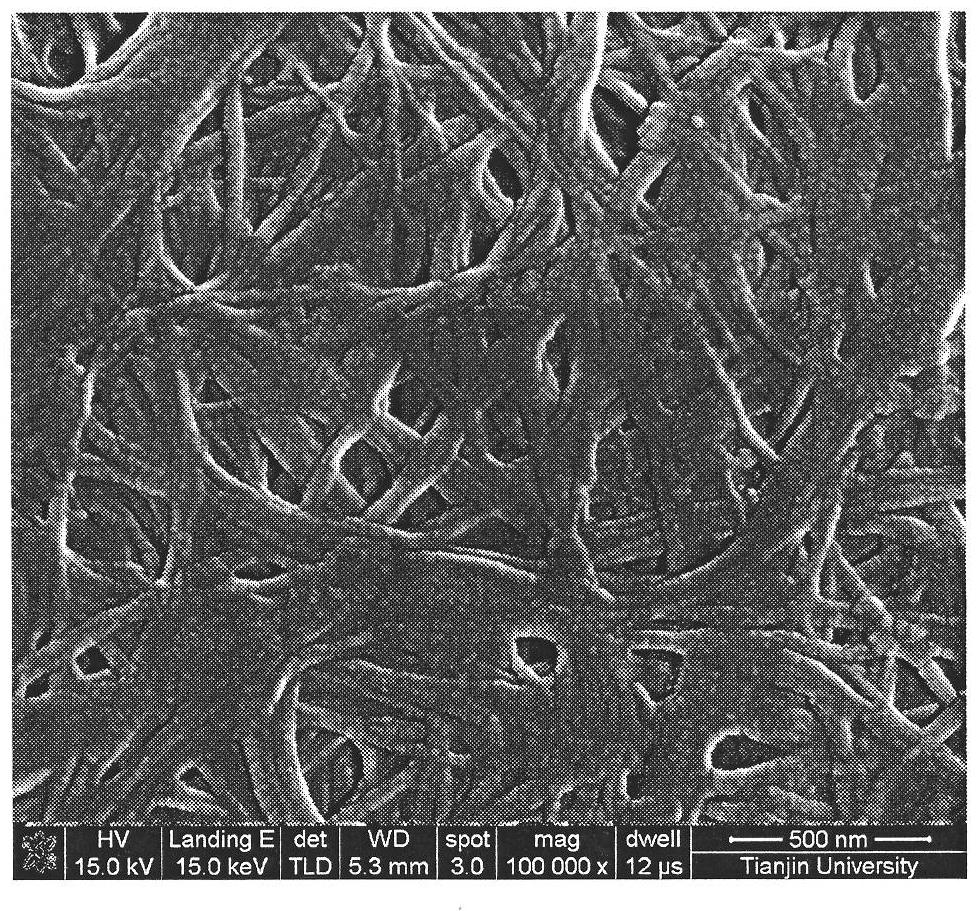

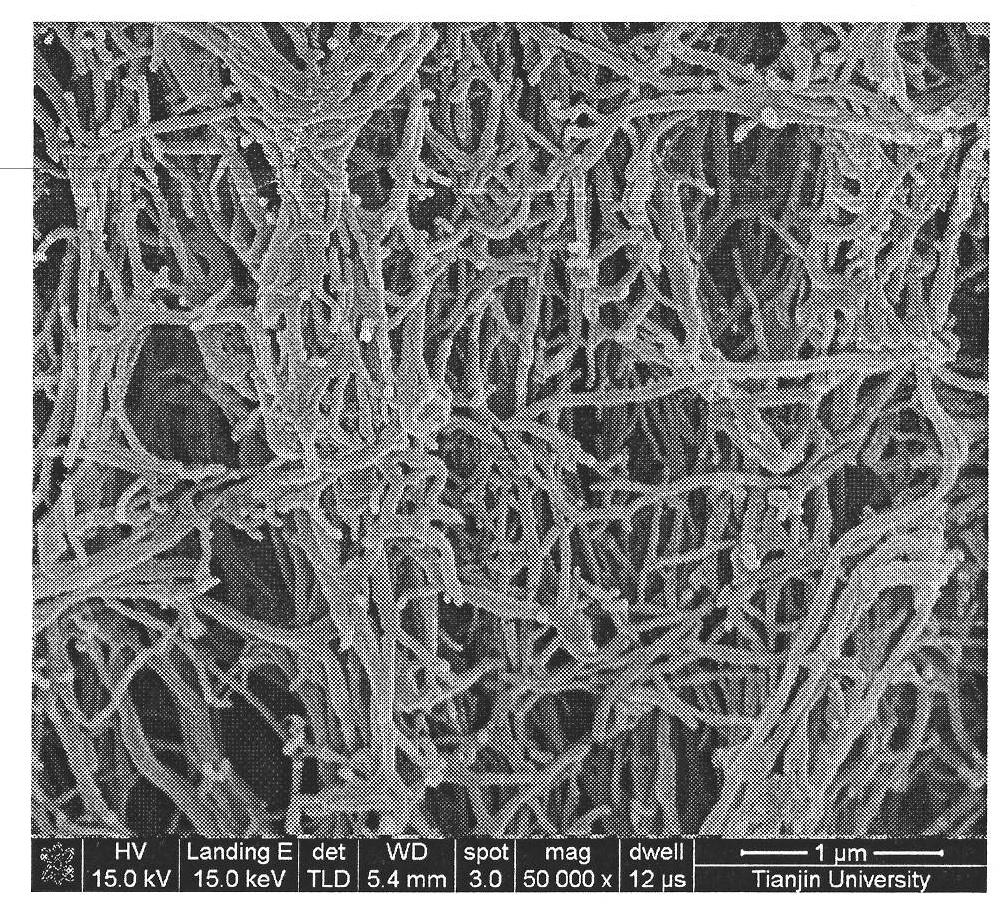

[0038] SEM analysis showed that the diameter of the bacterial filaments was in the range of 60-120nm, a dense network bifurcation structure was formed between the filaments, and a microporous structure was formed between the filaments, and the pore size of the microporous structure was 0.2-2 μm. Sodium silicate is added to the medium to obtain SiO with a diameter of about 30-60nm after mineralization by bacteria 2 Most of the particles are attached to the filaments of bacterial cellulose, and only a small amount of nanoparticles are embedded in the bacterial cellulose matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com