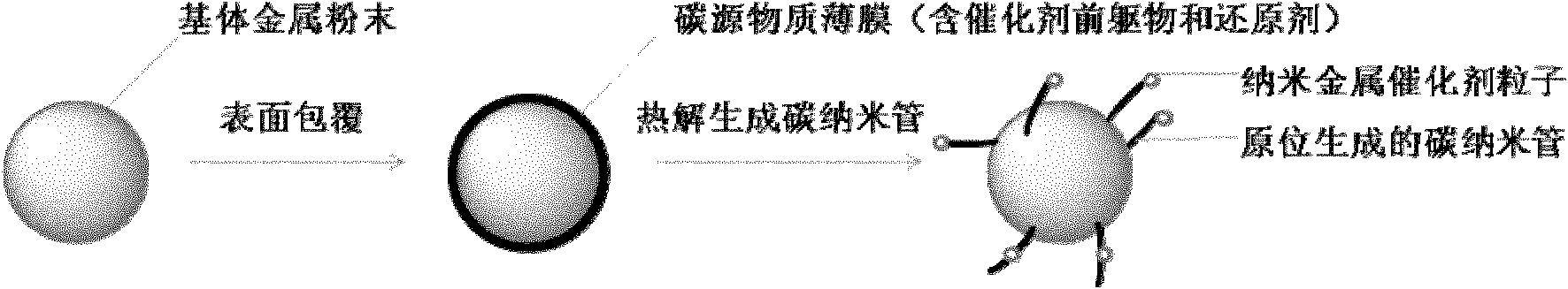

Carbon nano tube reinforced metal matrix composite material and in-situ preparation method thereof

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of composite materials technology, can solve the problems affecting the shape, size and distribution of nano-carbon reinforcements, the size of catalyst particles is not concentrated, and the process is complicated, and the shape is controllable. , the effect of suppressing growth and reunion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: 1.0g Fe (NO 3 ) 39H 2 O, 1.7g of glucose and 2.0g of polyvinyl alcohol were dissolved in 20ml of ethanol, magnetically stirred for 0.5h to obtain a uniform precursor solution, then 10g of aluminum powder was added to the precursor solution, magnetically stirred for 1.0h, and evenly distributed on the surface of the aluminum powder Coating the catalyst precursor and polyvinyl alcohol, and filtering and drying to obtain surface-coated aluminum powder. Then put the powder into N 2 Heating to 500° C. for 2 hours in a tube furnace under atmosphere protection to obtain carbon nanotube-reinforced aluminum matrix composite powder. Scanning electron microscope observations showed that a large number of carbon nanotubes were formed in situ, such as figure 2 shown. Transmission electron microscopy observations show that the in situ generated carbon nanotubes have a perfect graphitic structure, such as image 3 shown.

Embodiment 2

[0033] Embodiment 2: 0.6gNiCl 2 ·6H 2 O, 2.0g of citric acid and 2.0g of polyethylene glycol were dissolved in 20ml of pure water, magnetically stirred for 0.5h to obtain a uniform precursor solution, then 20g of iron powder was added to the precursor solution, magnetically stirred for 1.0h, The surface of the powder is uniformly coated with the catalyst precursor and polyethylene glycol, and the surface-coated iron powder is obtained through filtration and drying. Then put the powder into N 2 Heating to 800° C. for 1 hour in a tube furnace under atmosphere protection to obtain carbon nanotube-reinforced iron-based composite powder.

Embodiment 3

[0034] Example 3: Dissolve 0.5g ferrocene, 1.5g maltose and 2.0g ethylene glycol in 20ml ethanol, stir magnetically for 0.5h to obtain a uniform precursor solution, then add 23g copper powder to the precursor solution, magnetically Stir for 1.0 h, evenly coat the catalyst precursor and ethylene glycol on the surface of the copper powder, and filter and dry to obtain the surface-coated copper powder powder. Then put the powder into a tube furnace protected by an Ar atmosphere and heat it to 700° C. for 1.5 hours to react to obtain a carbon nanotube-reinforced copper-based composite powder.

[0035] Table 1. Process conditions of some embodiments

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com