Active group containing polyacrylate flexibilizer, preparation method thereof and epoxy resin adhesive modified by same

A polyacrylate, reactive group technology, used in epoxy resin adhesives, adhesives, adhesive additives, etc., can solve the problem of low shear strength and peel strength, cannot be used as structural adhesives, and epoxy resin adhesives have poor heat resistance. and other problems, to achieve the effect of good shear strength and peel strength, excellent shear strength and peel strength, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

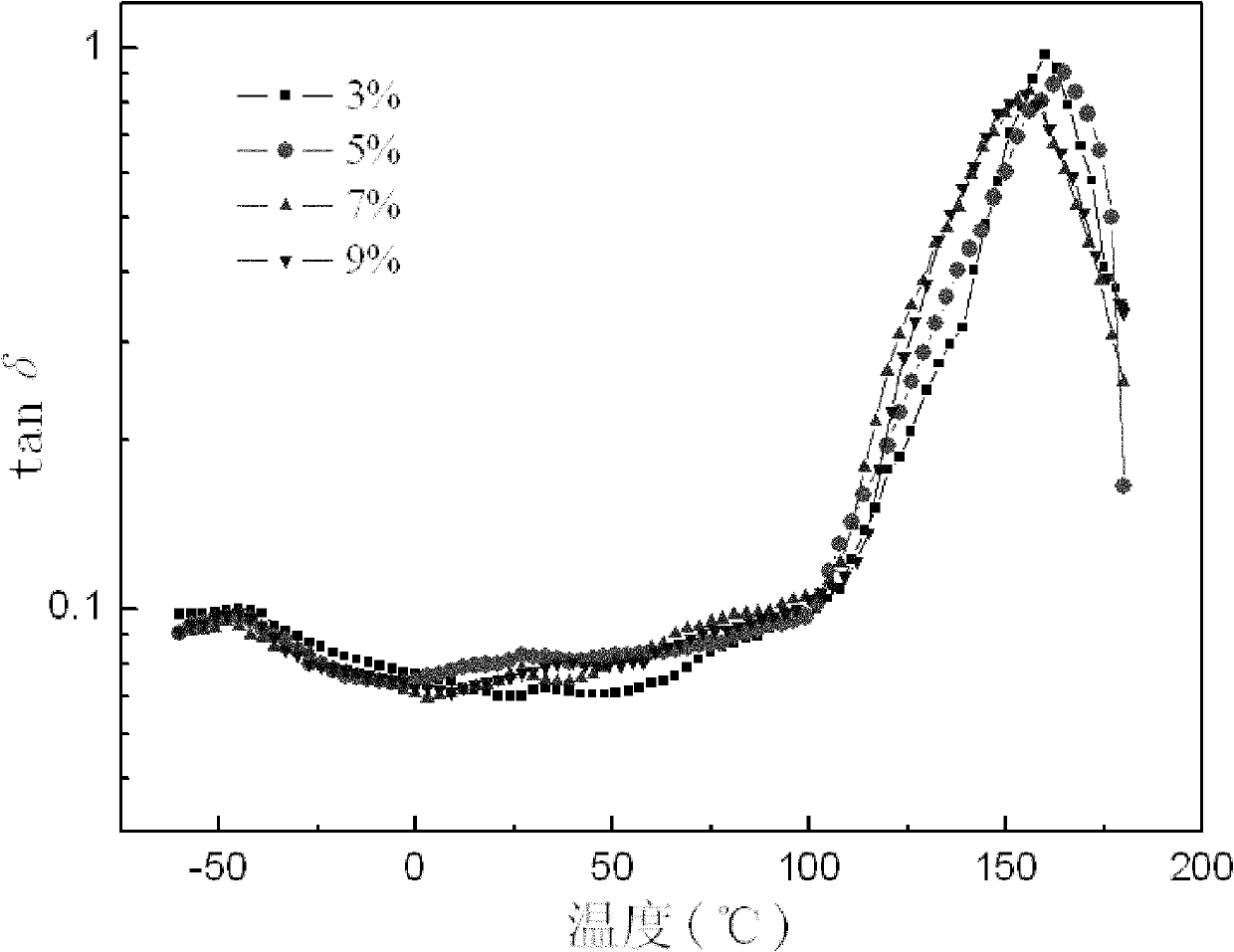

[0015] Embodiment 1: This embodiment is a polyacrylate toughening agent containing active groups. The polyacrylate toughening agent containing active groups consists of 60 to 75 parts of soft monomer, 15 to 25 parts of hard monomer in parts by weight. Monomer, 5-15 parts of functional monomer, epoxy resin E-51 dispersion medium equal to the total weight of monomer, benzoyl peroxide initiator accounting for 3%-5% of total monomer weight, accounting for monomer It is obtained by reacting 1% to 3% of dodecyl mercaptan chain transfer agent and 0.5% of hydroquinone chain terminator accounting for the total weight of the monomers. The molecular weight of the polyacrylate toughening agent is 3000 to 5000; wherein The total weight of the monomer refers to the weight sum of the soft monomer, the hard monomer and the functional monomer, and the total weight of the control monomer is 100 parts; wherein, the soft monomer is butyl acrylate (BA) or isooctyl acrylate ester (EHA), the hard mo...

specific Embodiment approach 2

[0017] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the polyacrylate toughening agent containing active groups consists of 70-75 parts of soft monomer, 18-25 parts of hard monomer, 5-25 parts by weight. 9 parts of functional monomers, epoxy resin E-51 dispersion medium equal to the total weight of the monomers, benzoyl peroxide initiator accounting for 3% to 5% of the total weight of the monomers, accounting for 1% to 5% of the total weight of the monomers It is obtained by reacting 3% of dodecyl mercaptan chain transfer agent and 0.5% of hydroquinone chain terminator accounting for the total weight of monomers, wherein the functional monomer is acrylic acid (AA). Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0018]Specific embodiment three: the difference between this embodiment and specific embodiment one is that the polyacrylate toughening agent containing active groups consists of 60-75 parts of soft monomer, 15-25 parts of hard monomer, 10-25 parts by weight. 15 parts of functional monomers, epoxy resin E-51 dispersion medium equal to the total weight of the monomers, benzoyl peroxide initiator accounting for 3% to 5% of the total weight of the monomers, accounting for 1% to 5% of the total weight of the monomers It is obtained by reacting 3% of dodecyl mercaptan chain transfer agent and 0.5% of hydroquinone chain terminator accounting for the total weight of monomers, wherein the functional monomer is glycidyl methacrylate (GMA). Other parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com