Adhesive sheet for supporting and protecting semiconductor wafer, back grinding method for semiconductor wafer

A technology of semiconductors and adhesive sheets, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, adhesive types, etc., and can solve the problems of residual glue, wafer damage, insufficient bonding of adhesives and wafer surfaces, etc. problems, to achieve the effect of preventing residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

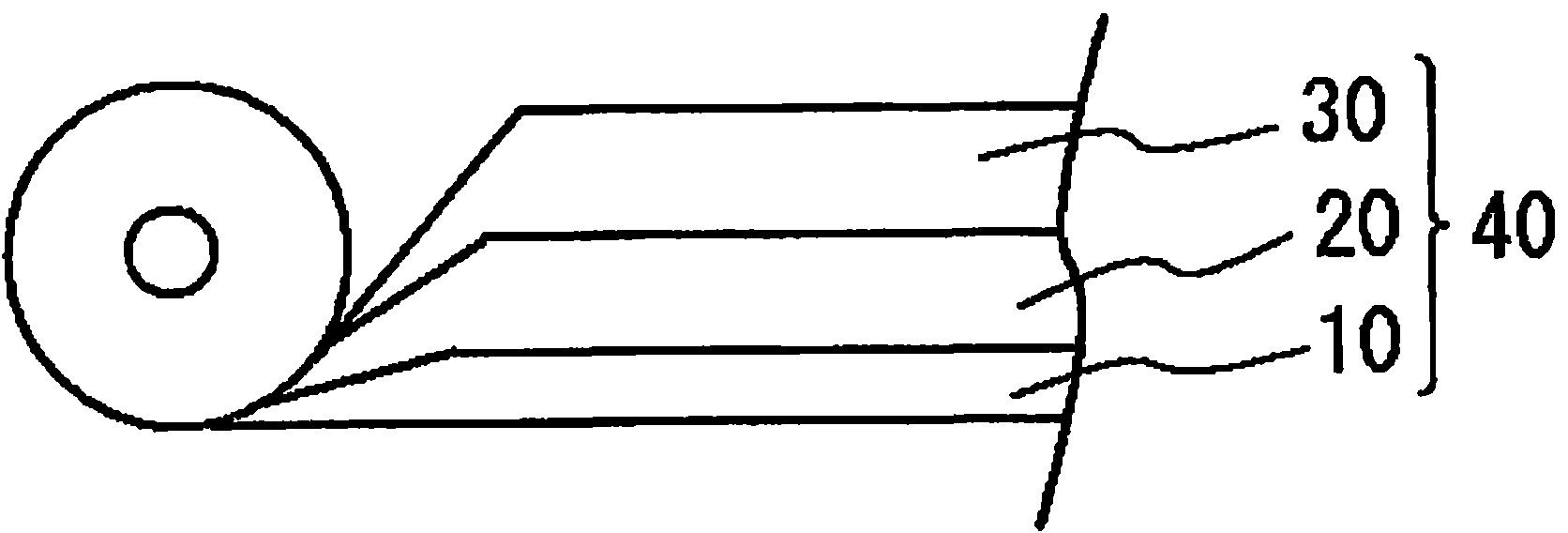

[0186] Such as figure 1 As shown, as the substrate layer 10, an ethylene-vinyl acetate copolymer (EVA) film with a thickness of 115 μm was used, and an intermediate layer 20 (thickness: 60 μm) and an adhesive layer 30 (thickness: 5 μm) were formed thereon.

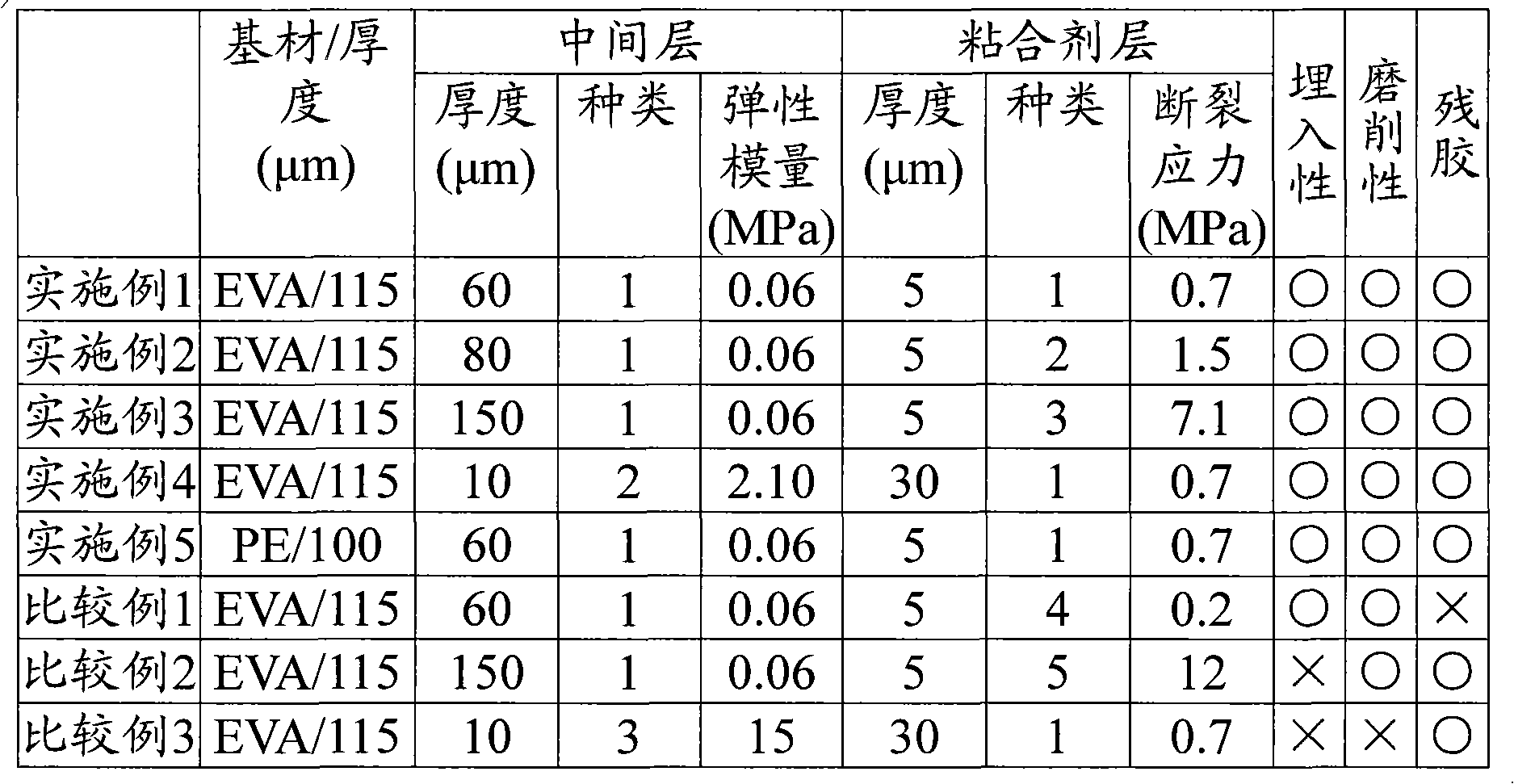

Embodiment 2~5 and comparative example 1~3

[0188] As the substrate layer, an ethylene-vinyl acetate copolymer (EVA) film with a thickness of 115 μm or a polyethylene (PE) film with a thickness of 100 μm was used.

[0189] According to Example 1, the intermediate layer and the adhesive layer shown in Table 1 were formed on the substrate layer according to the thicknesses in Table 1, respectively.

[0190] Each obtained adhesive sheet was adhered to a silicon wafer, ground, and the adhesive sheet was peeled off, and the following evaluations were performed. Moreover, 25 adhesive sheets of each Example and a comparative example were prepared and evaluated. The results are shown in Table 1.

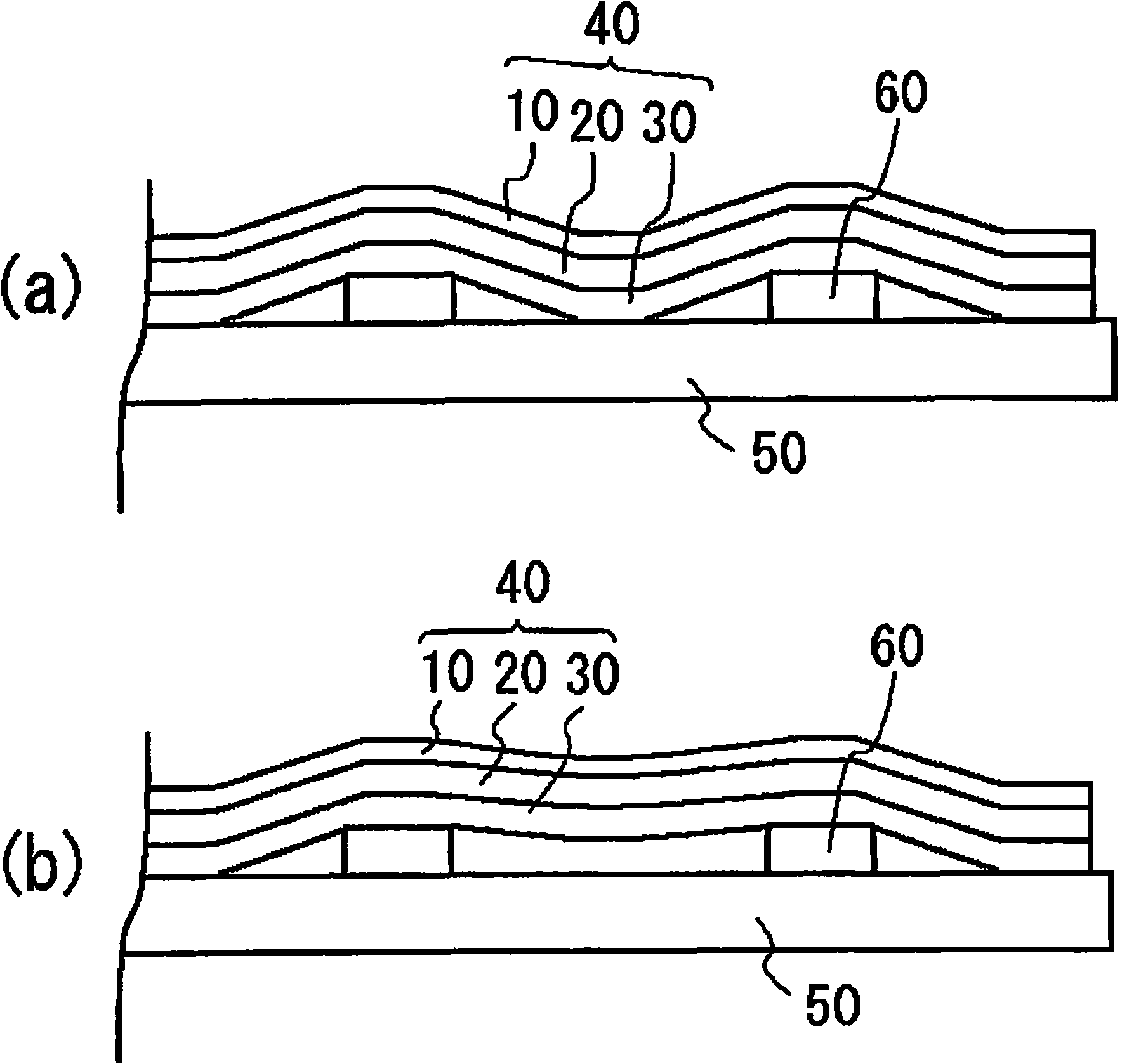

[0191] paste

[0192] Each adhesive sheet was pasted so that an adhesive layer was disposed on the surface side of an 8-inch silicon wafer on which dummy bump electrodes were formed. Bump electrodes with a height of 50 μm and a diameter of 100 μm were formed on the silicon wafer in a lattice shape with a pitch P of 200 μm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com