Vertical atomized chemical fiber molding method

A chemical fiber and molding method technology, applied in fiber processing, wet spinning, melt spinning, etc., can solve the problem of equipment investment, high land occupation and energy consumption, affecting the spinnability of the subsequent process, and the curing effect is not obvious, etc. problems, to achieve uniform cooling and solidification, reduce frictional resistance, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

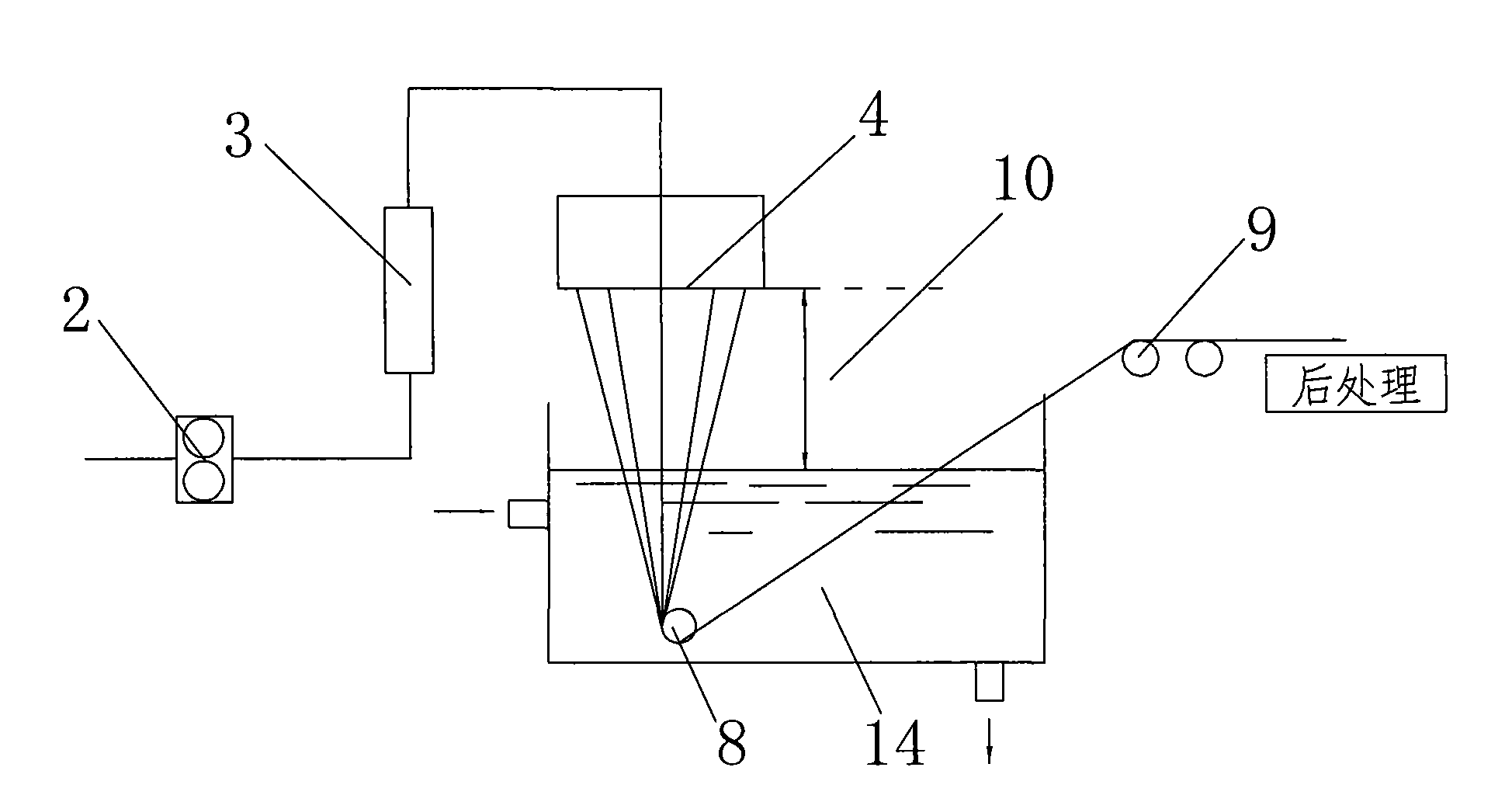

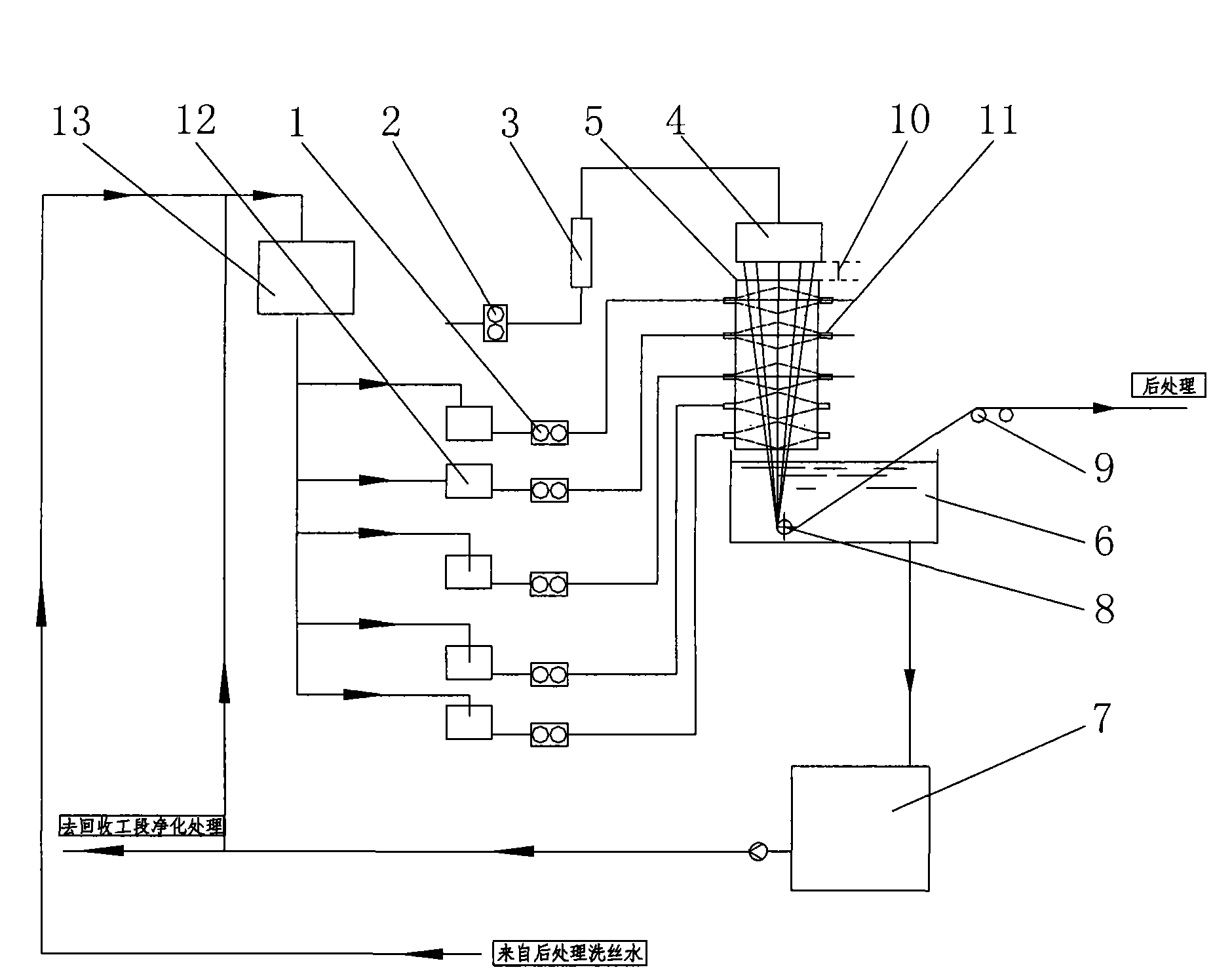

[0034] Such as image 3 As shown, a vertical spray chemical fiber forming method:

[0035] When performing solvent spinning, the spinning raw material is firstly the spinning stock solution, the temperature is 60-90°C, and the solvent concentration of oxidized methylmorpholine (NMMO) is 70-90%. After 3, it enters the spinneret 4 of the spinning assembly, and the thin stream (filament) of the stock solution extruded downward through the guide hole of the spinneret 4 passes through the air gap 10 between the spinneret 4 and the coagulation chamber 5, and the mist can be adjusted. The spray nozzle 11 is used to fill the air gap 10 with mist. The temperature of the mist liquid is room temperature, and the air gap 10 is filled with air at room temperature. The fiber surface cooling and solidification conditions are mild, the probability of fibrillation is greatly reduced, and the air is continuously replenished into the coagulation chamber through the air gap along with the downwa...

Embodiment 2

[0043] Such as image 3 As shown, a vertical spray chemical fiber forming method:

[0044] The difference between embodiment 2 and embodiment 1 is that embodiment 2 is melt spinning, the spinning raw material is 100% spinning raw material melt, the temperature is 200~350 ℃, and the atomizing nozzle 11 sprays out the bath in the coagulation chamber The liquid is water, and the temperature is 16-30°C. The atomized water droplets sprayed on the surface of the filament meet the melt above 200°C, immediately vaporize and dissipate into the air, and the heat entering the water tank is only a small part; The water only needs to be equipped with a circulating cooling tower cooling system to be cooled to normal temperature. Considerable cooling capacity is saved, and the quality of filament forming is not affected in any way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com