High-strength shock-resistance steel bars and production method thereof

A technology of anti-seismic steel bars and steel bars, which is applied in the field of anti-seismic steel bars for construction and its preparation, which can solve the problems of large energy consumption, low strength level, and high alloy cost, and achieve the effect of simple alloy elements, low price, and high strength-to-yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] First, after smelting by conventional steelmaking process, it is continuously cast into a round billet, so that the weight percentage of each component in the steel is shown in Table 1; the above-mentioned billet is heated to 1200 °C and kept for 45 minutes; the above-mentioned billet is cooled to 1000 °C Rolling is carried out at 850° C., and the rolling is completed to obtain a steel bar with a diameter of 45 mm, which is air-cooled to room temperature.

Embodiment 2

[0109] Firstly, after being smelted by conventional steelmaking process, it is continuously cast into a steel slab, so that the weight percentage of each component in the steel is shown in Table 1; the above-mentioned steel bar blank is heated to 1200°C and kept for 45min; the above-mentioned steel bar blank is cooled to 1050°C At 900°C, the steel bar blanks were rolled, and the rolling was finished at 900°C to obtain steel bars with a diameter of 40mm. The above steel bars were air-cooled to 300°C, collected and bundled, and cooled slowly.

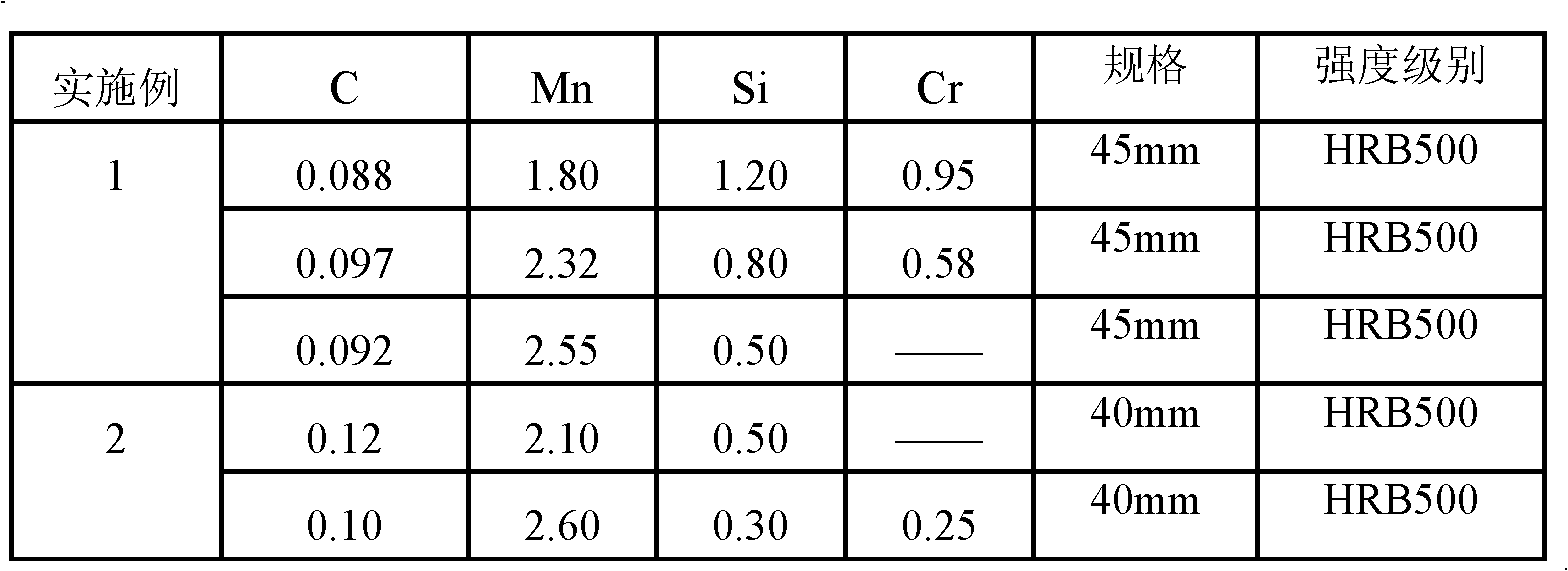

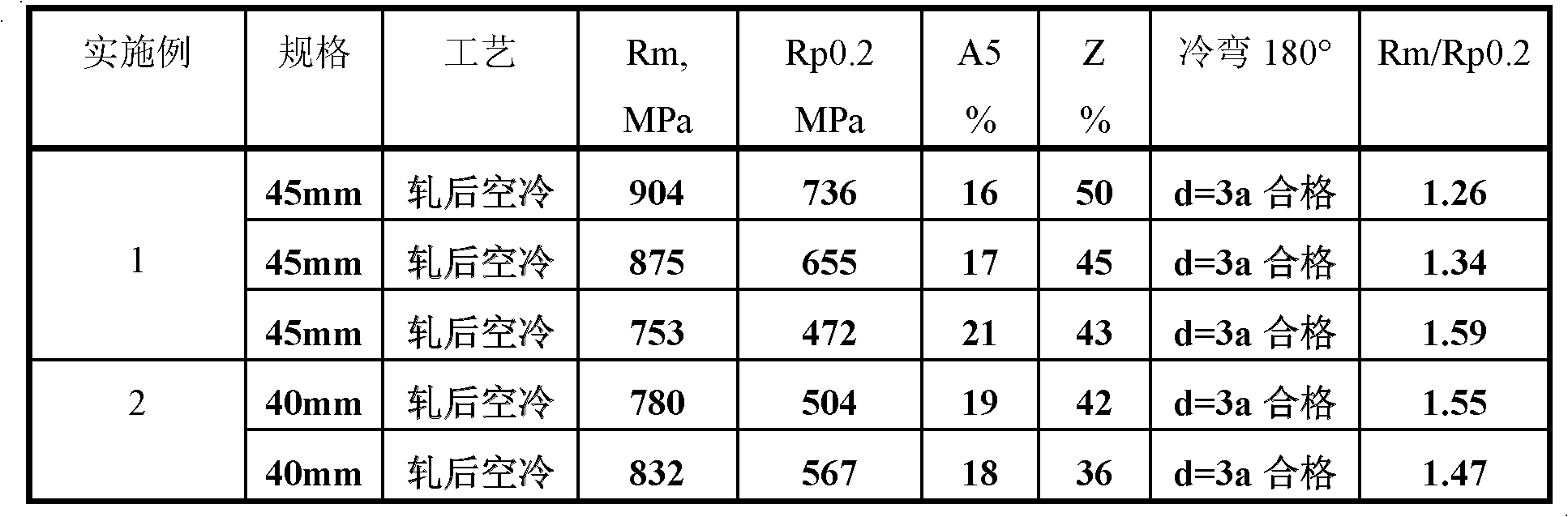

[0110] Table 1, chemical composition (wt%) of the embodiment of the present invention

[0111]

[0112] σ is used to evaluate steel bars by using conventional measurement methods such as steel strength and tensile strength, and the measured performance parameters are shown in Table 2.

[0113] Table 2, technology, organization and performance of the embodiment of the present invention

[0114]

[0115] 1-2. Preparation of high-stre...

Embodiment 3

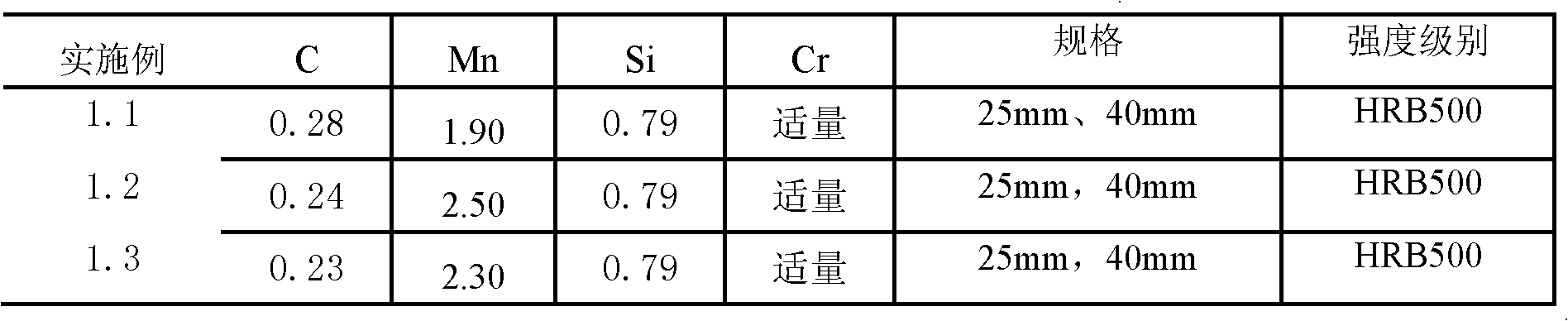

[0125] Firstly, after being smelted by the conventional steelmaking process, it is continuously cast into a steel bar blank, so that the weight percentage of each component in the steel is shown in Table 3; the above steel bar blank is heated to 1200°C and kept for 1 hour; then, the above steel bar blank is cooled When the temperature reaches 1050°C, the steel bar blanks are rolled, and when the temperature reaches 960°C, the rolling is completed to obtain a steel bar with a diameter of 40mm; and the above steel bars are air-cooled to 270°C--320°C, collected and bundled to cool slowly to room temperature.

[0126] In addition, there are steels with three components under the same process in this example, which are respectively recorded as Examples 1.1, 1.2, and 1.3. Embodiment performance is as shown in table 4.

[0127] Table 3, chemical composition (wt%) of the embodiment of the present invention

[0128]

[0129] Table 4, the mechanical property of the embodiment of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com