Hot metal desulphurization slag foaming agent and preparation method thereof

A technology of molten iron desulfurization slag and foaming agent, which is applied in the direction of improving process efficiency, can solve the problems of low utilization rate of casting residual slag, discarded casting residual slag, slow slag removal speed, etc. The effect of cost reduction and slag removal efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) 9 parts by weight of casting residue (casting residue R=3.2) is cooled and crushed to particles with a particle diameter of 3 mm, and then the above particles are ground to a particle diameter of 1 mm;

[0029] (2) Add 1 part by weight of calcium carbide to the casting slag and grind until the particle size is 0.5 mm, then mix for 15 minutes to obtain a mixed dry material;

[0030] (3) Add 0.4 parts by weight of adhesive to the mixed dry material while mixing, and then process it into a spherical slag with a diameter of 30 mm.

[0031] (4) The spherical slag is dried at 80° C. for 6 hours to obtain the foaming agent of the present invention.

Embodiment 2

[0033] (1) 7 parts by weight of casting slag (casting slag R = 3.2) is cooled and crushed to particles with a particle size of 4 mm, and then the particles are ground to a particle size of 1.5 mm using a ball mill;

[0034] (2) Add 3 parts by weight of limestone to the casting slag and finely grind it with a Raymond mill until the particle size is 0.5 mm, then mix for 12 minutes to obtain a mixed dry material;

[0035] (3) While stirring, add 0.2 parts by weight of adhesive to the mixed dry material, and then process it into a spherical slag with a diameter of 25 mm.

[0036] (4) The spherical slag is dried at 90° C. for 4 hours to obtain the foaming agent of the present invention.

Embodiment 3

[0038] (1) 8 parts by weight of casting residue (casting residue R=3.2) is cooled and crushed to particles with a particle diameter of 3 mm, and then the particles are ground to a particle diameter of 1.2 mm;

[0039] (2) adding 1 weight part each of silicon carbide and magnesite to the casting slag and grinding until the particle size is 0.5 mm, and then mixing for 10 minutes to obtain a mixed dry material;

[0040] (3) While mixing, add 0.3 parts by weight of adhesive to the mixed dry material, and then process it into a spherical slag with a diameter of 28 mm.

[0041] (4) The spherical slag is dried at 100° C. for 3 hours to obtain the foaming agent of the present invention.

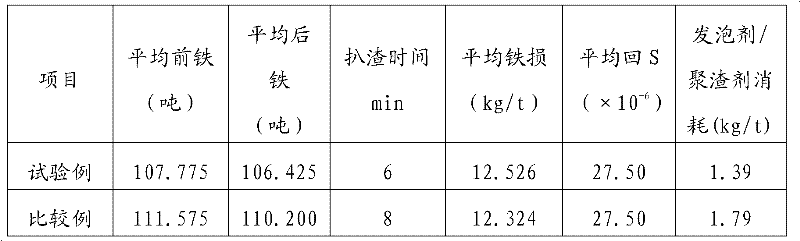

[0042] Take the actual slagging effect of molten iron passivation magnesium desulfurization in Wuhan Iron and Steel Co. kg, make the desulfurization slag foam, and carry out the slag removal after the desulfurization slag is foamy, and its effect is compared with the conventional slag gathering agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com