Method for converting C9+ heavy arenes into light arenes

A technology for heavy aromatics and light aromatics, applied in chemical instruments and methods, organic chemistry, hydrocarbon oil cracking, etc., to achieve the effects of reduced total hydrogen consumption, extended operating cycle, and reduced loss of aromatic rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

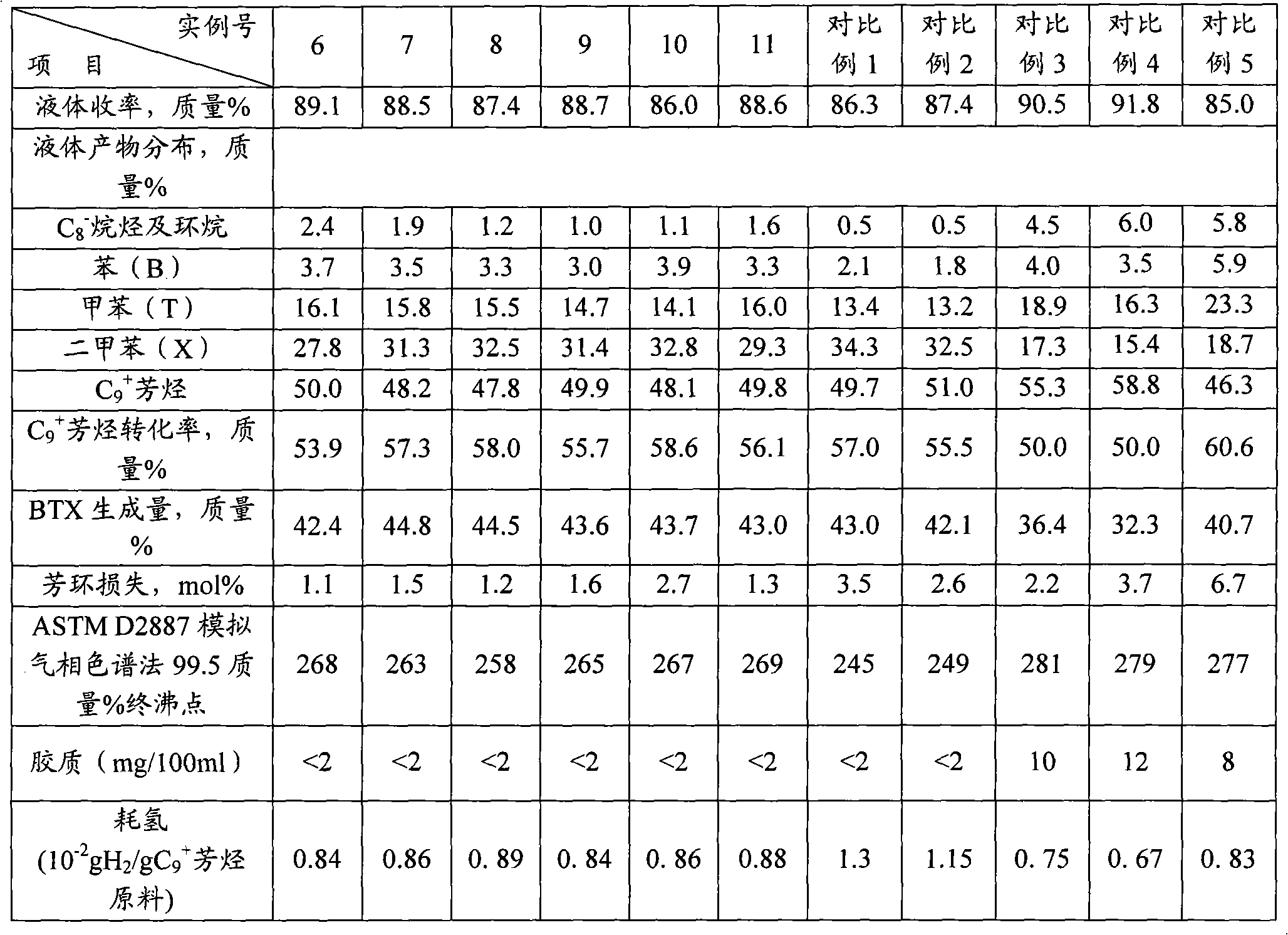

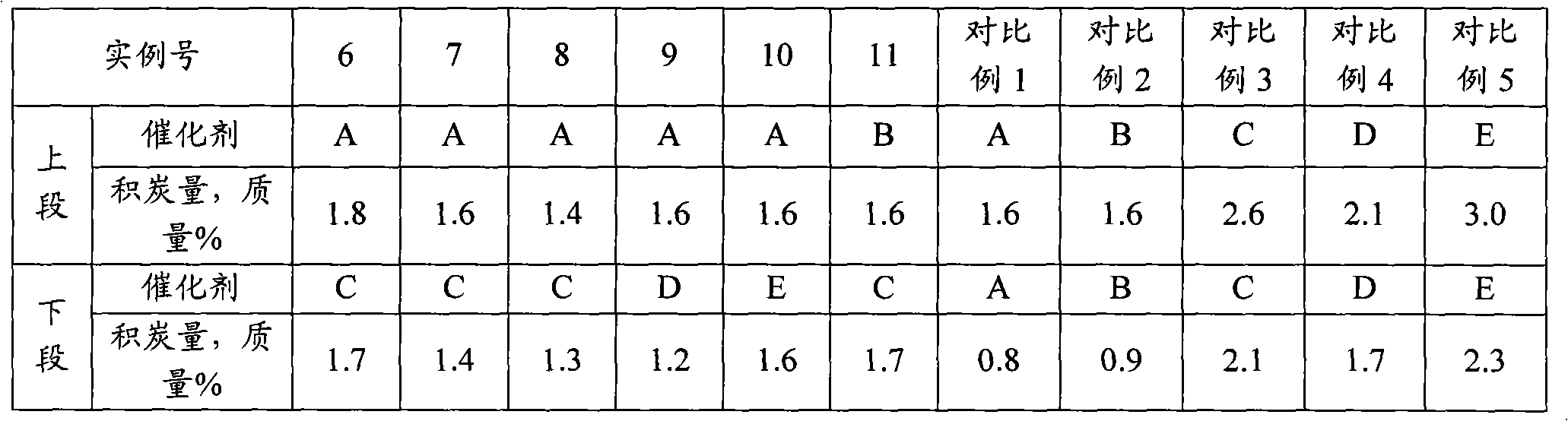

Examples

preparation example Construction

[0017] The preparation method of the iridium-containing catalyst is as follows: first impregnating the molded carrier with an impregnating solution prepared with an Ir-containing compound, and then drying, high-temperature water chlorine activation treatment and reduction to obtain the catalyst. The iridium-containing compound used to prepare the immersion solution is preferably chloroiridic acid, ammonium chloroiridate, iridium chloride or iridium oxide. In order to distribute the iridium evenly in the carrier, it is preferable to add a halide, preferably hydrochloric acid, to the impregnating solution, so that the Cl therein - Competitive adsorption with iridium ions. The liquid / solid volume ratio during immersion is preferably 1.0-3.0:1, and the immersion temperature is preferably 20-40°C. Filter after impregnation, dry the solid at 100-200°C, and then conduct water chlorine activation treatment.

[0018] The water chlorine activation treatment is a process in which the d...

example 1

[0030] Preparation of iridium-containing catalysts.

[0031] Get 128 grams of aluminum hydroxide powder (SB powder, produced by Changling Catalyst Factory), add 38.4 grams of concentration and knead it with 5% by mass nitric acid and 25.6 milliliters of deionized water, extrude, and pelletize the strips at 120° C. Dry for 8 hours, and bake at 550° C. for 6 hours to obtain 100 g of γ-alumina carrier.

[0032] Get 100 grams of gamma-alumina carriers, use the mixed solution of chloroiridic acid and hydrochloric acid as the impregnating solution and soak for 24 hours at 25° C., containing 0.45 mass % of Ir and 2.5 mass % of HCl in the impregnating solution (both based on dry base alumina carrier base calculation), add deionized water to make the liquid / solid volume ratio 1.5. After impregnation, filter, and dry the obtained solid at 120°C for 12 hours, 550°C, H 2 Under the condition that the O / HCl molar ratio is 20, water chlorine is activated for 6 hours, 350°C, H 2 Under the ...

example 2

[0034] The catalyst was prepared according to the method of Example 1, except that the prepared impregnating solution contained 0.30% by mass of Ir, and the obtained catalyst B had an Ir content of 0.30% by mass and a chlorine content of 1.3% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com