High-power density motor with multidirectional magnetic field

A high power density, magnetic field technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of easy knocking, reduced operating efficiency, inter-turn short circuit, etc. The effect of high performance, high flux utilization, and low leakage flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

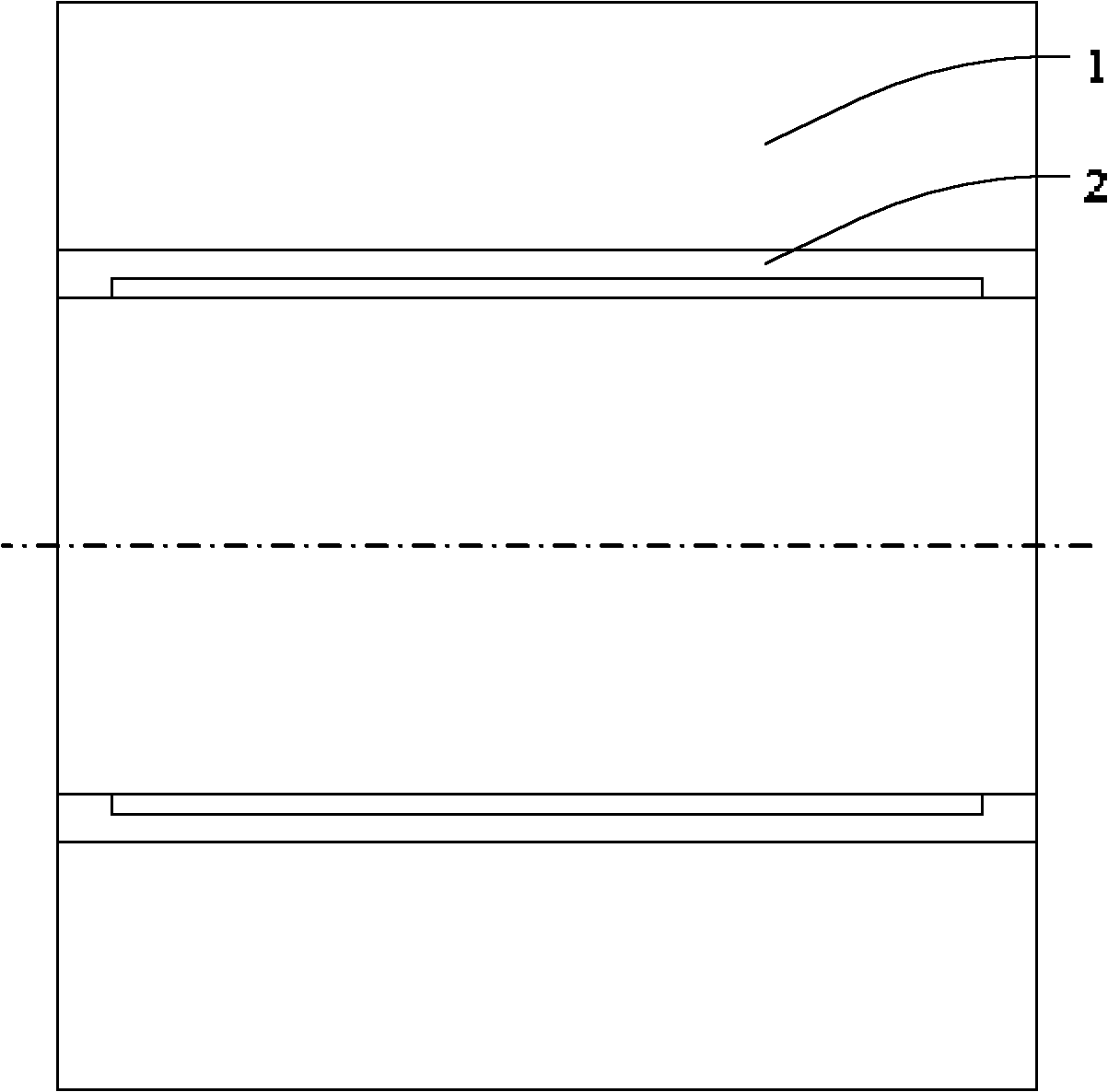

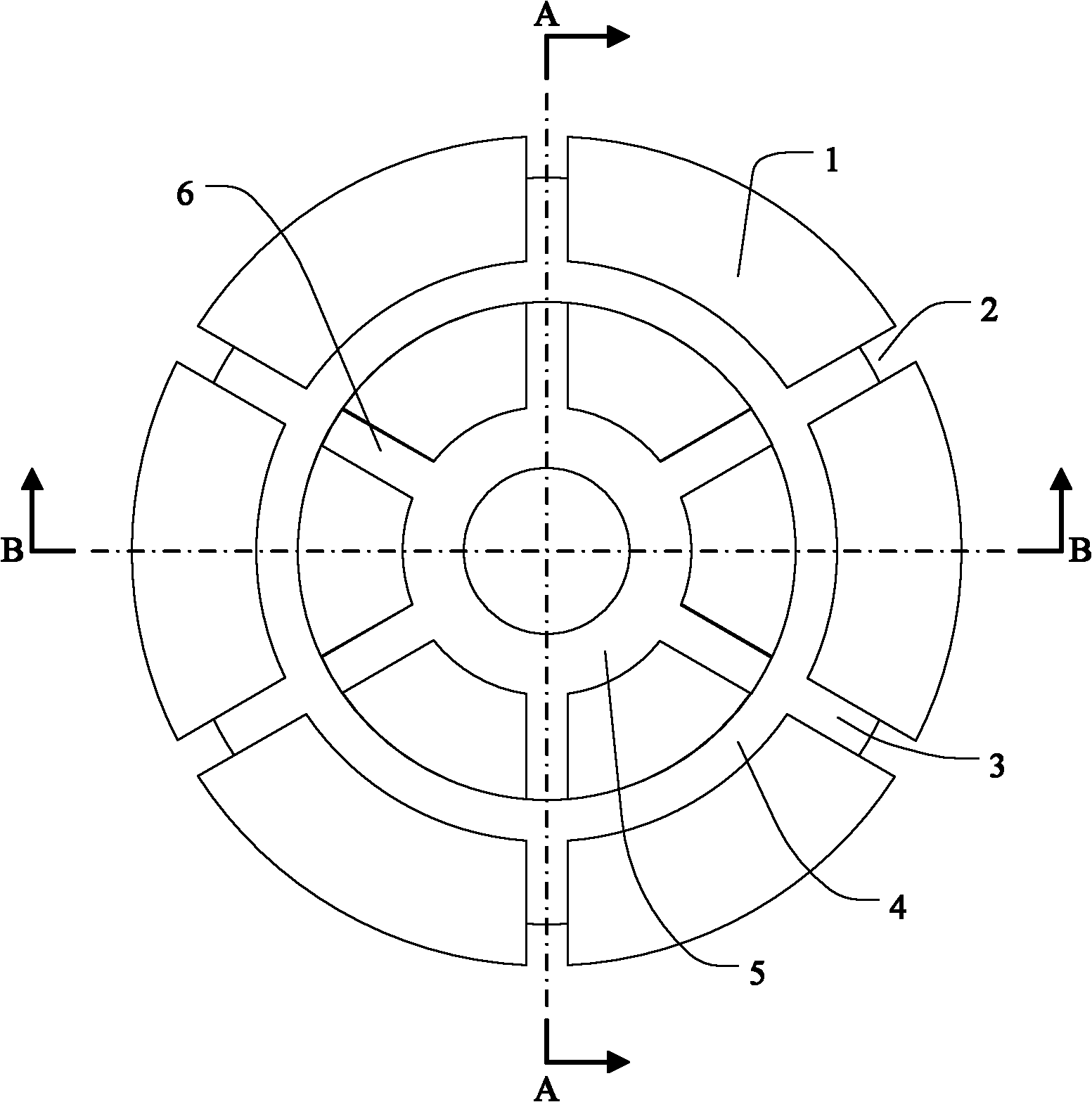

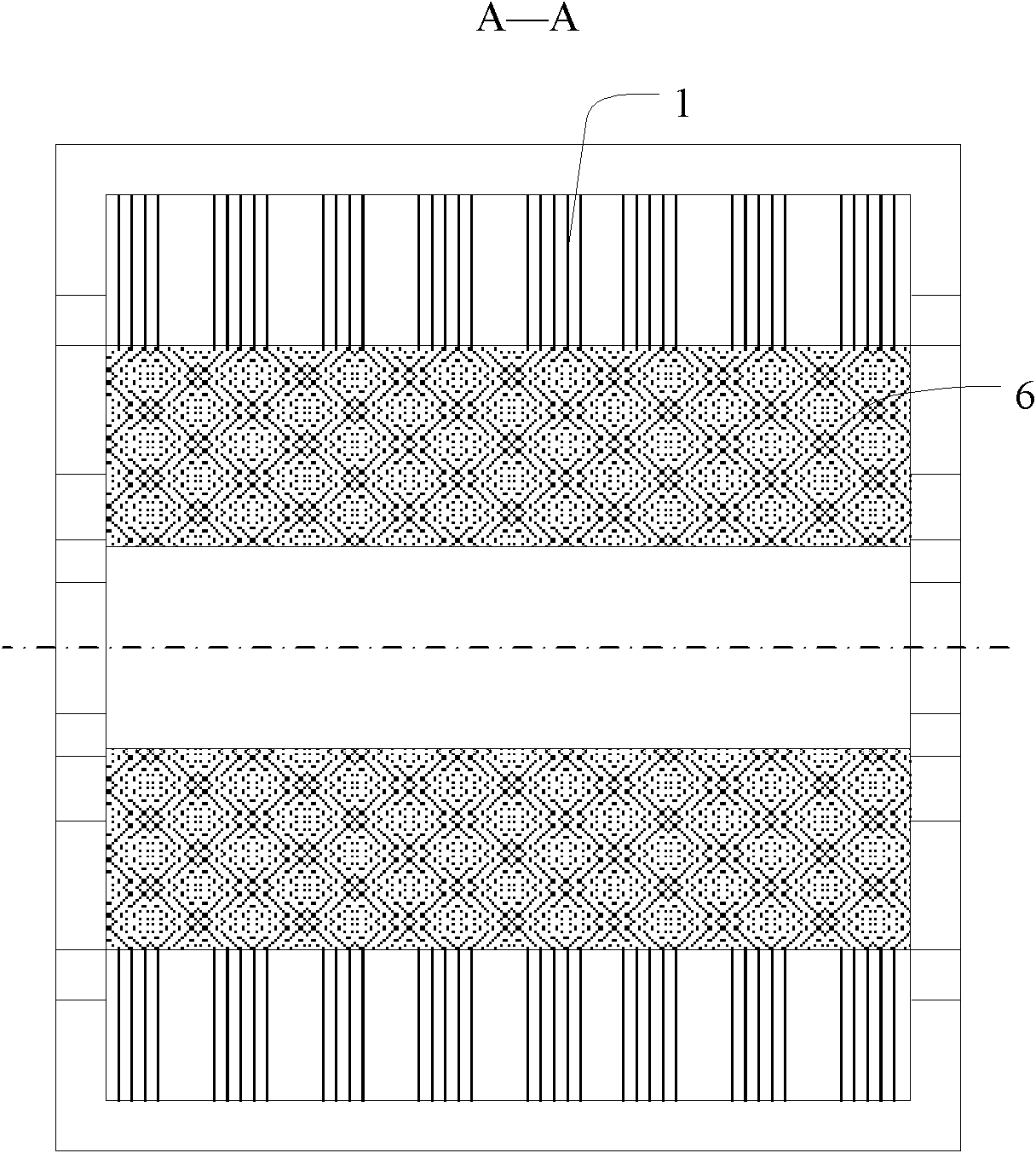

[0041] The high power density motor with the structure of the present invention is composed of several main parts such as a stator, an intermediate rotor, a left end rotor, a right end rotor, a left end bearing, a right end bearing, and a hollow shaft, specifically including: a stator core 1; slot 2, radial slot 3, annular slot 4; stator magnetic isolation ring 5 and stator magnetic isolation plate 6 inside stator core 1; stator winding 7; cable 8 for connecting stator winding 7 and external power supply; The hollow shaft 9 of the line hole 10; the rotor core 11 of the left end rotor and the right end rotor; the outer ring main magnetic pole 12 and the inner ring main magnetic pole 13 pasted on the rotor iron core 11 of the left end rotor and the right end rotor; the rotor cores of the left end rotor and the right end rotor 11 Internal end rotor magnetic isolation ring 14 and end rotor magnetic isolation plate 15; intermediate rotor core 16; intermediate rotor magnetic isolatio...

Embodiment approach 2

[0061] When the controller of the motor needs to detect the position of the motor rotor, Hall sensors can be embedded in the cylindrical surface of the stator core 1, the end faces on both sides, or in the axial groove 2 and the radial groove 3. The specific placement method is the same as that of the existing permanent magnet. The placement method of the magneto is the same, and the input and output lines of the Hall sensor are connected to the external controller through the cable 8 .

[0062] Others are the same as the above embodiment.

Embodiment approach 3

[0064] In order to further eliminate the influence of cogging torque on the performance of the motor, while adjusting the α angle, the geometric centerlines of the radially opposite outer ring main magnetic poles 12 and inner ring main magnetic poles 13 on the left and right end rotors can be staggered by a certain angle, The size of this angle is not easy to exceed the slot pitch angle corresponding to the axial slot 2, and the specific value should be obtained through electromagnetic calculation according to actual requirements.

[0065] Others are the same as the above embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com