One-component room temperature vulcanizing silicone fireproof sealant and preparation method thereof

A fireproof sealant, vulcanized silicone technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc. Improve the cost and other issues, and achieve the effects of excellent weathering resistance, good adhesion, and excellent high and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 90 parts of α, ω-dihydroxy polydimethylsiloxane, 30 parts of methyl silicone oil, 70 parts of nano-calcium carbonate and flame retardant (ZL-01 environmentally friendly flame retardant, manufacturer: Silicon Materials of Chengdu High-tech Zone Co., Ltd.) 40 parts were sequentially added to the vacuum kneader and stirred, and heated while stirring. When the temperature reached 80°C, vacuuming was started, and the vacuum degree was 0.08MPa. After the temperature reached 150°C, the heating was stopped, and the vacuum was stirred for 3 hours. The cooled material is ground with a three-roll mill until the particle size is ≤1 μm to obtain the base material.

[0024] At room temperature, add the above-mentioned base material into a vacuum high-speed disperser, then add 2 parts of r-aminopropyltriethoxysilane, 3 parts of dibutyltin dilaurate, and 15 parts of methyl tributylketoximosilane in sequence. Under the conditions of vacuum degree 0.08MPa, rotation speed 20rpm, stirring ...

Embodiment 2

[0026] Add 110 parts of α, ω-dihydroxy polymethyl vinyl siloxane, 25 parts of methyl silicone oil, 90 parts of silicon micropowder and 50 parts of environmentally friendly flame retardant into the vacuum kneader and stir, and heat while stirring. When it reaches 100°C, start vacuuming, the degree of vacuum is 0.06MPa, stop heating after the temperature reaches 150°C, and stir in vacuum for 2 hours. The cooled material is ground with a three-roll mill until the particle size is ≤1 μm to obtain the base material.

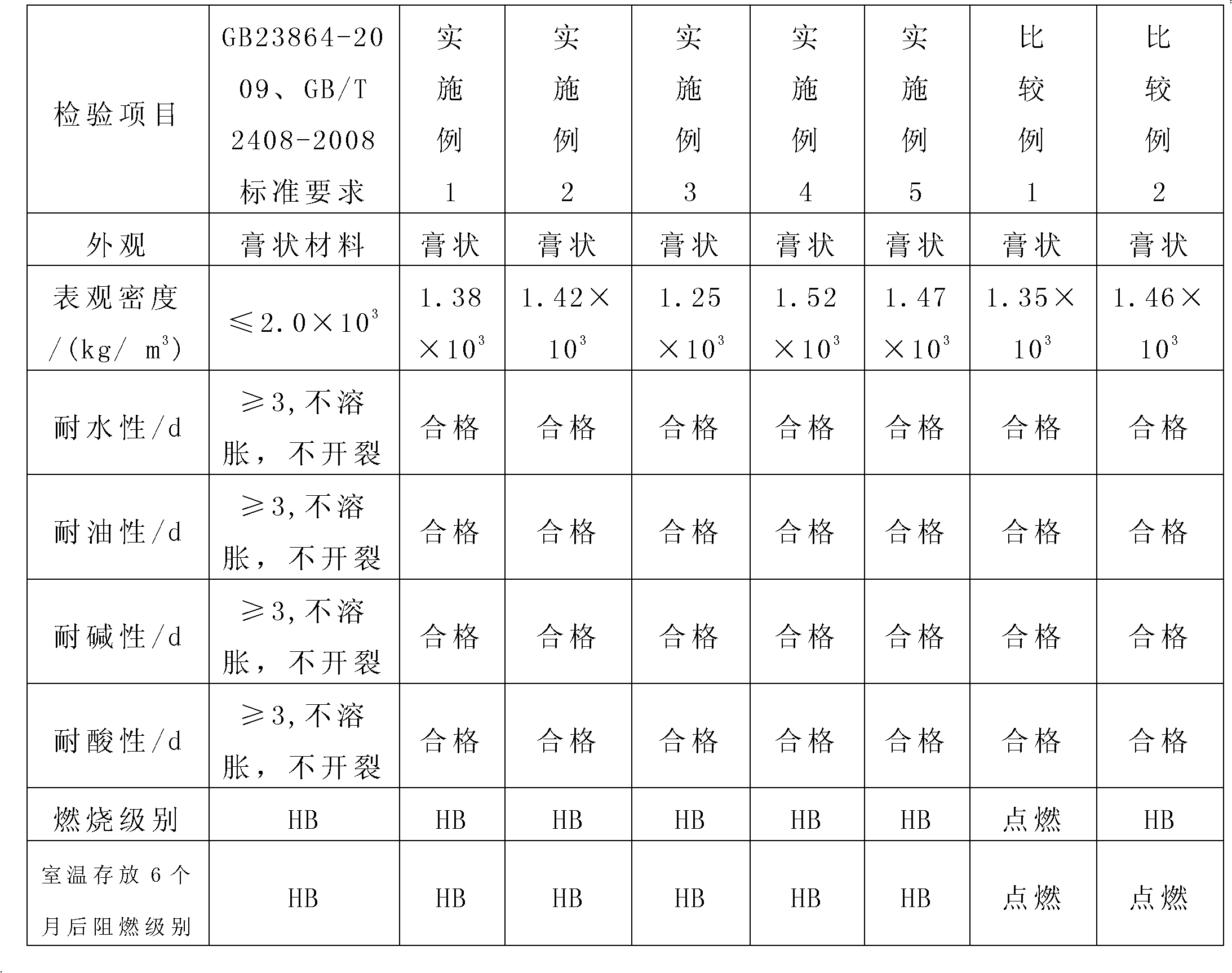

[0027] At room temperature, add the above-mentioned base material into a vacuum high-speed disperser, and then add 5 parts of r-aminopropyltrimethoxysilane, 1 part of dibutyltin diacetate, and 20 parts of vinyl tributylketoximosilane in turn. 0.07MPa, rotating speed 35rpm, stirring and reacting for 80 minutes, a one-component room temperature vulcanized silicone fireproof sealant was prepared. The product performance test results are shown in Table 1.

Embodiment 3

[0029] Add 100 parts of α, ω-dihydroxy polydivinyl siloxane, 20 parts of methyl silicone oil, 80 parts of fumed silica and 30 parts of environmentally friendly flame retardant into the vacuum kneader and stir, and heat while stirring. When the temperature reaches 90°C, start vacuuming, the degree of vacuum is 0.065MPa, stop heating when the temperature reaches 150°C, and stir in vacuum for 4 hours. The cooled material is ground with a three-roll mill until the particle size is ≤1 μm to obtain the base material.

[0030] At room temperature, put the above base material into a vacuum high-speed disperser, and then add 1 part of r-(2,3 glycidoxy)propyltrimethoxysilane, 2 parts of dibutyltin dioctoate, phenyltributanone oxime 10 parts of base silane, under the conditions of vacuum degree of 0.06MPa and rotation speed of 100rpm, stirred and reacted for 40 minutes to prepare a one-component room temperature vulcanized silicone fireproof sealant. The product performance test results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com