Method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in coking plant

A technology for thiocyanate and desulfurization waste liquid, which is applied in the field of preparation of thiocyanate and sulfate, can solve the problems such as difficulty in improving product quality, and achieve the effect of less consumption, less solute loss, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

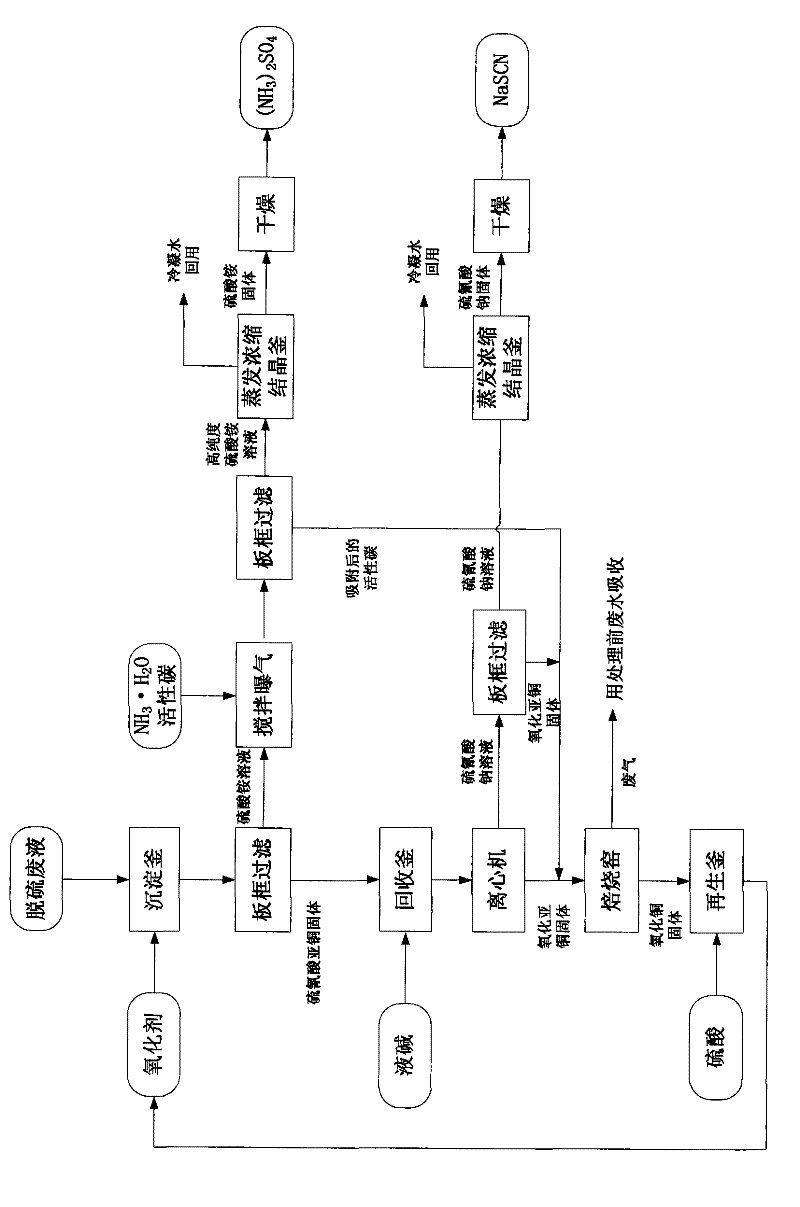

[0029] Refer to attached figure 1 , present embodiment is the method for preparing sodium thiocyanate and ammonium sulfate with the desulfurization waste liquid that HPF method desulfurization effluxes, and concrete process is as follows:

[0030] 1. Pour the desulfurization waste liquid discharged from HPF desulfurization into the precipitation reactor, take the copper sulfate solid, prepare a saturated copper sulfate solution at 80 ° C, and carry out the batching according to the volume ratio of the saturated copper sulfate solution to the desulfurization waste liquid of 1:2, and put Add the prepared saturated copper sulfate solution into the precipitation reactor and mix with the desulfurization waste liquid, mix and stir, keep the reaction temperature at 80°C, and stir for 45 minutes to obtain a slurry containing cuprous thiocyanate and having a pH of 0-3;

[0031] 2. Using a plate and frame filter or a centrifuge, the slurry obtained in step 1 containing cuprous thiocyana...

Embodiment 2

[0055] Present embodiment is the method for preparing ammonium thiocyanate and ammonium sulfate with the desulfurization waste liquid that PDS method desulfurization effluxes, and process is similar to embodiment 1, and concrete process is as follows:

[0056] Take copper sulfate pentahydrate solid, prepare saturated solution of copper sulfate at 95°C, mix according to the volume ratio of saturated copper sulfate solution and desulfurization waste liquid at 1:1, stir, keep the reaction temperature at 95°C, and stir for 10 minutes; then use a centrifuge Carry out solid-liquid separation to obtain cuprous thiocyanate solid and remaining waste liquid.

[0057] Discharge the remaining waste liquid into the decolorization oxidation reactor, add granular activated carbon at the rate of 1 kg of activated carbon / ton of the remaining waste liquid, use ammonia water to adjust the pH to 5, and carry out oxygen aeration for 360 minutes. Then a plate and frame filter is used for solid-liqu...

Embodiment 3

[0060] The present embodiment is the method for preparing potassium thiocyanate and sodium sulfate with the desulfurization waste liquid discharged from the desulfurization of the improved ADA method, similar to embodiment 1, and the specific process is as follows:

[0061] Prepare saturated copper sulfate solution at 50°C, mix according to the volume ratio of saturated copper sulfate solution and desulfurization waste liquid at 1:2.5, stir, keep the reaction temperature at 40°C, and stir for 80 minutes; then use a plate and frame filter for solid-liquid separation, Obtain cuprous thiocyanate solid and remaining waste liquid.

[0062] Discharge the remaining waste liquid into the decolorization oxidation reactor, add powdered activated carbon at the rate of 50kg activated carbon per ton of the remaining waste liquid, use sodium hydroxide liquid caustic soda to adjust the pH to 7, and carry out ozone aeration for 10 minutes. Then a centrifuge is used for solid-liquid separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com