Method for preparing active carbon material by using waste and old polyethylene glycol terephthalate

A polyethylene terephthalate, a technology for preparing activated carbon, applied in the direction of solid waste removal, etc., can solve the problems of use limitation, transparency and sanitation problems, low physical properties of recycled materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

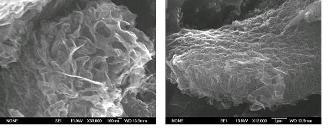

Image

Examples

Embodiment 1

[0016] Rinse the waste PET with deionized water and put it in an oven at 40°C for 24 hours. The dried waste PET is crushed into 80 mesh powdered PET with a crusher. Take 1g waste PET powder and 4g K 2 CO 3 Grind and mix well in a mortar. Then put the uniformly mixed raw materials into a tubular heating furnace, under the protection of nitrogen at a flow rate of 100mL / min, heat to a carbonization temperature of 500℃ at a heating rate of 10℃ / min, and keep it for 120min; The heating rate is heated to the activation temperature of 800℃, and the activation time is 60min; after the activation is completed in N 2 Naturally cool to room temperature under protection. Finally, the sample after carbonization and activation is washed with 0.5mol / L hydrochloric acid solution for about 5 times, and then washed with deionized water for about 5 times. The washed product is placed in an oven at 120°C for 24 hours to obtain 0.246 g Dry activated carbon products.

[0017] According to the nation...

Embodiment 2

[0019] Rinse the waste PET with deionized water and put it in an oven at 40°C for 24 hours. The dried waste PET is crushed into 80 mesh powdered PET with a crusher. Weigh 4g of activator K 2 CO 3 Dissolve in 20ml of deionized water. After dissolving, add 1g of PET powder and mix thoroughly. After mixing, put it in an oven and bake at 90°C for 24 hours to obtain a solid mixture. Then put the uniformly mixed raw materials into a tubular heating furnace, under the protection of nitrogen at a flow rate of 100mL / min, heat to a carbonization temperature of 500℃ at a heating rate of 10℃ / min, and keep it for 120min; The heating rate is heated to the activation temperature of 800℃, and the activation time is 60min; after the activation is completed in N 2 Naturally cool to room temperature under protection. Finally, the carbonized and activated sample was washed with 0.5mol / L hydrochloric acid solution for about 5 times, and then washed with deionized water for about 5 times. The washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com