Medical magnesium alloy biodegradability in-vitro dynamic simulation test equipment

A technology of biodegradation and dynamic simulation, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as difficult to accurately predict the biodegradation performance of materials/device in vivo, unavoidable shearing effect, discount of clinical reference value, etc., to improve R&D efficiency and R&D quality, compact structure, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

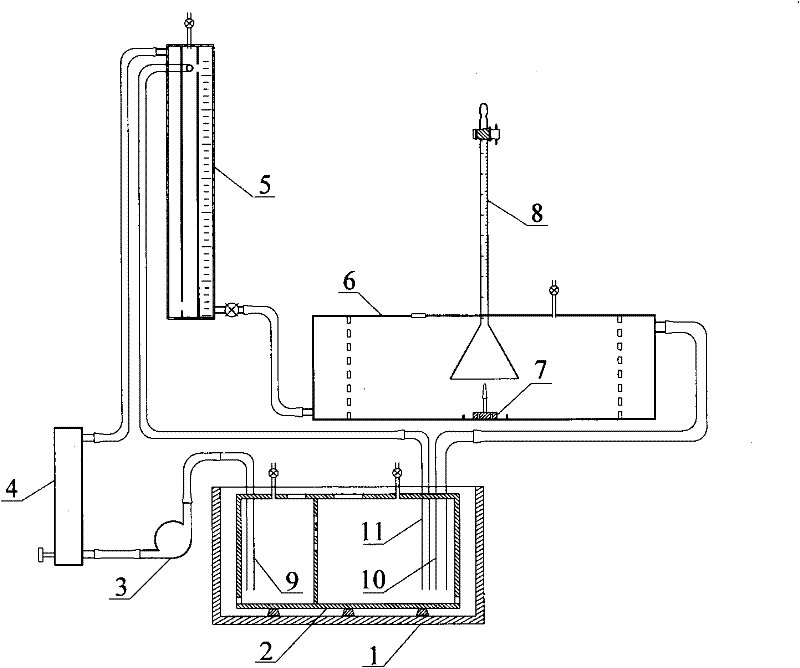

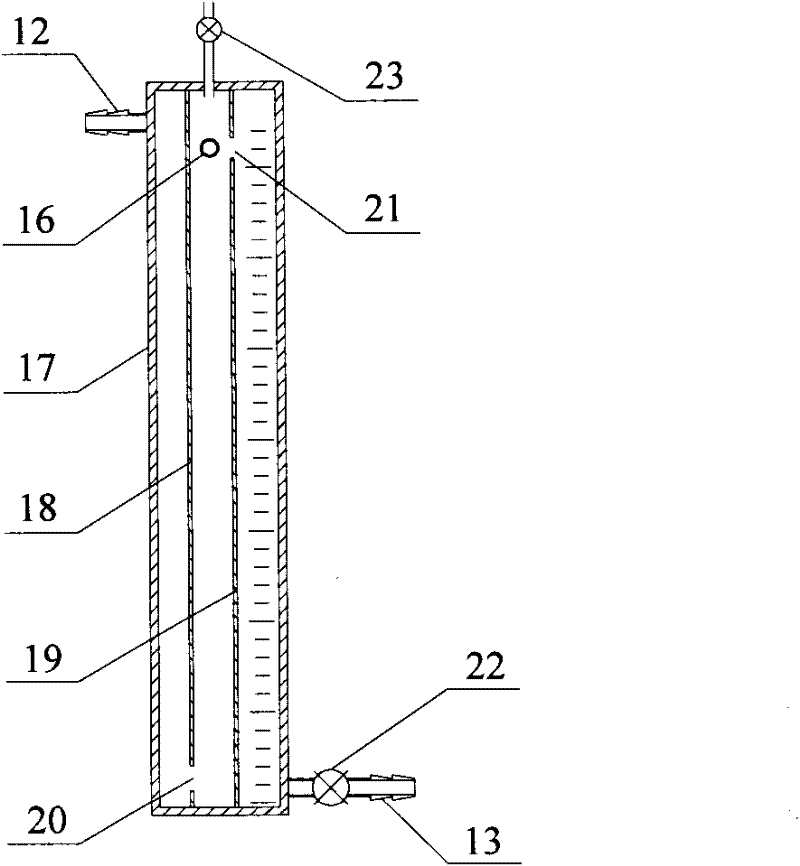

[0037] Taking the dynamic simulation test of the biodegradability of the medical magnesium alloy by the present invention as an example, the usage of the present invention is described in detail below: the pre-configured test medium such as Hank's simulated body fluid etc. is injected through the supply port 32 on the top of the liquid storage tank 2 Liquid storage tank 2; turn on the power switch of constant temperature tank 1, preset the temperature, heat the test medium and keep it constant temperature; carry out metallographic grinding, cleaning, drying, Micro-arc / anodizing, bionic passivation and other pre-treatments, and then screw / press it into the loading end 44 of the lower sample carrier 7; fix the lower sample carrier 7 to the test chamber 6 through the positioning hole 41 and the positioning pin 25 Bilge; open the circulation pump 3, and send the test medium into the power tank 5 and the test chamber 6; fix the gas gauge 8 vertically directly above the sample, adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com